Dust suppressant and preparation method and application thereof

A technology of dust suppressant and moisturizing agent, applied in the field of dust suppressant and its preparation, can solve the problems of low dust suppression efficiency, equipment corrosion, long degradation time, etc., so as to improve the wetting efficiency, strengthen the bonding characteristics, and improve the moisturizing effect. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

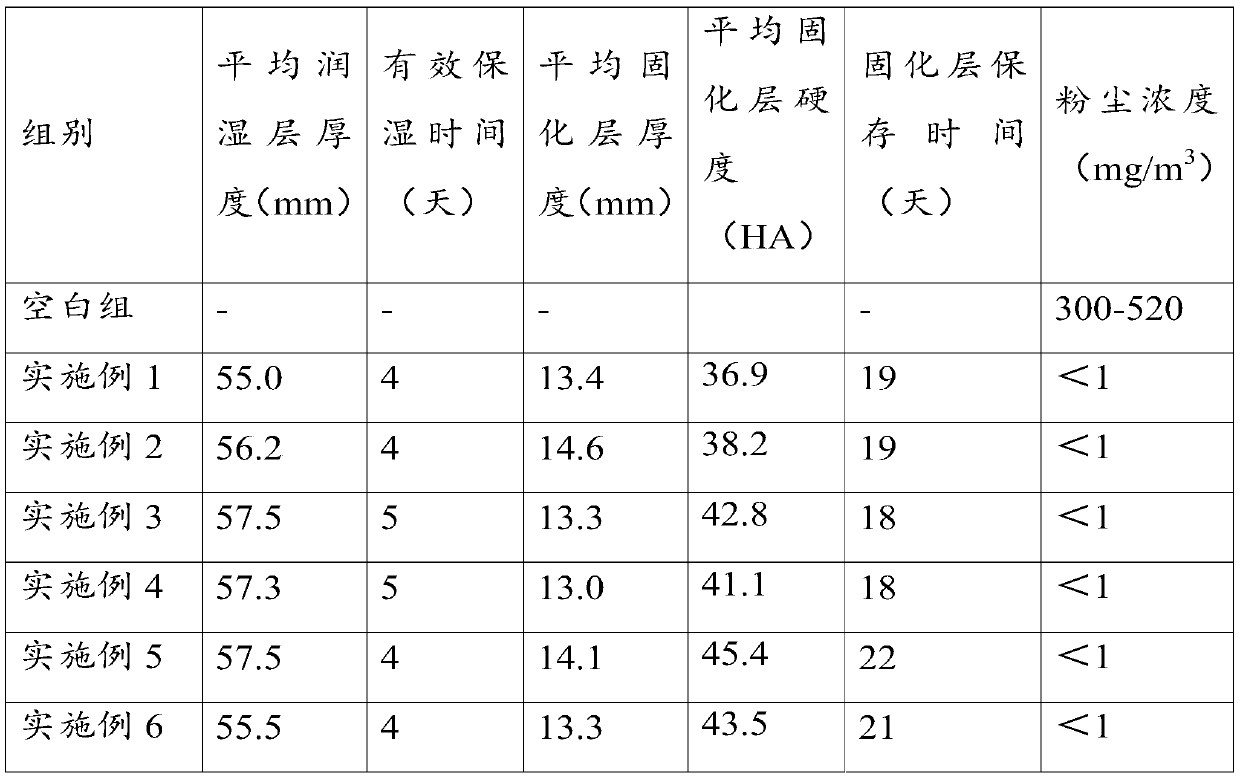

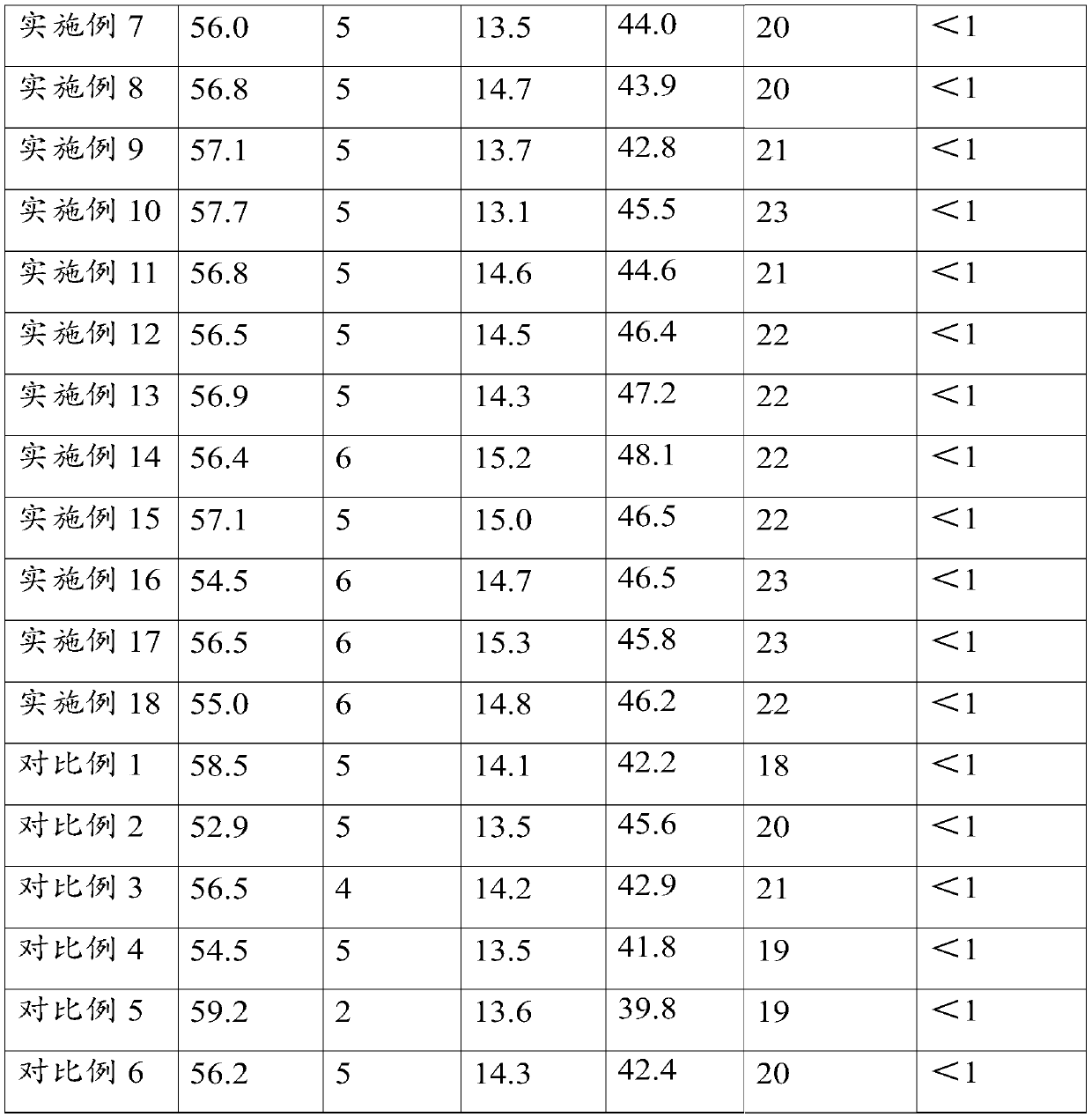

Examples

preparation example Construction

[0076] According to another aspect of the present invention, a method for preparing the above-mentioned dust suppressant is provided, comprising the following steps: uniformly mixing the components to obtain the dust suppressant. The method has simple process, and the prepared dust suppressant has the advantages of high dust suppression efficiency, safety, environmental protection and low cost.

[0077] In a preferred embodiment, the vegetable gum, humectant, wetting agent, thickener and optional bactericide are mixed once, then mixed with water for the second time, and the pH of the solution is adjusted to obtain the dust suppressant . In this preferred embodiment, the raw materials except water are firstly mixed, and then mixed with water for the second time, and then the pH is adjusted to reach a suitable pH to obtain the dust suppressant.

[0078] Preferably, the conditions for the secondary mixing include: the stirring speed is 800-1000 rpm, and the stirring time is 30-5...

Embodiment 1

[0086] A dust suppressant, comprising the following components in parts by mass: 62 parts of vegetable glue, 24 parts of humectant, 8 parts of wetting agent and 2.5 parts of thickener, and water, the concentration of dust suppressant is 0.15wt% , pH is 7;

[0087] The vegetable gum is guar gum, the humectant is sodium carboxymethylcellulose and carboxymethyl starch with a mass ratio of 1:1, the wetting agent is cetyltrimethylammonium chloride, and the thickener is a molecular weight of The polyacrylamide of 13 million; The viscosity of the aqueous solution of the sodium carboxymethyl cellulose of 2wt% is 750cps;

[0088] The dust suppressant is prepared by the following method: mix vegetable glue, humectant, wetting agent and thickener once, then mix with water twice (stirring speed is 700rpm, stirring time is 25min), adding citric acid to adjust the pH of the solution , get dust suppressant.

Embodiment 2

[0090] A dust suppressant, comprising the following components in parts by mass: 60 parts of vegetable glue, 28 parts of humectant, 12.5 parts of wetting agent, 3 parts of thickener, and water.

[0091] The mass parts of plant gum, humectant, wetting agent and thickener are different from Example 1 in this example, and the rest are all the same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Average volume particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com