Preparation method of optical-grade potassium metaphosphate

An optical-grade potassium metaphosphate technology, which is applied in the field of preparation of optical-grade potassium metaphosphate, can solve problems affecting the optical properties of glass and achieve strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

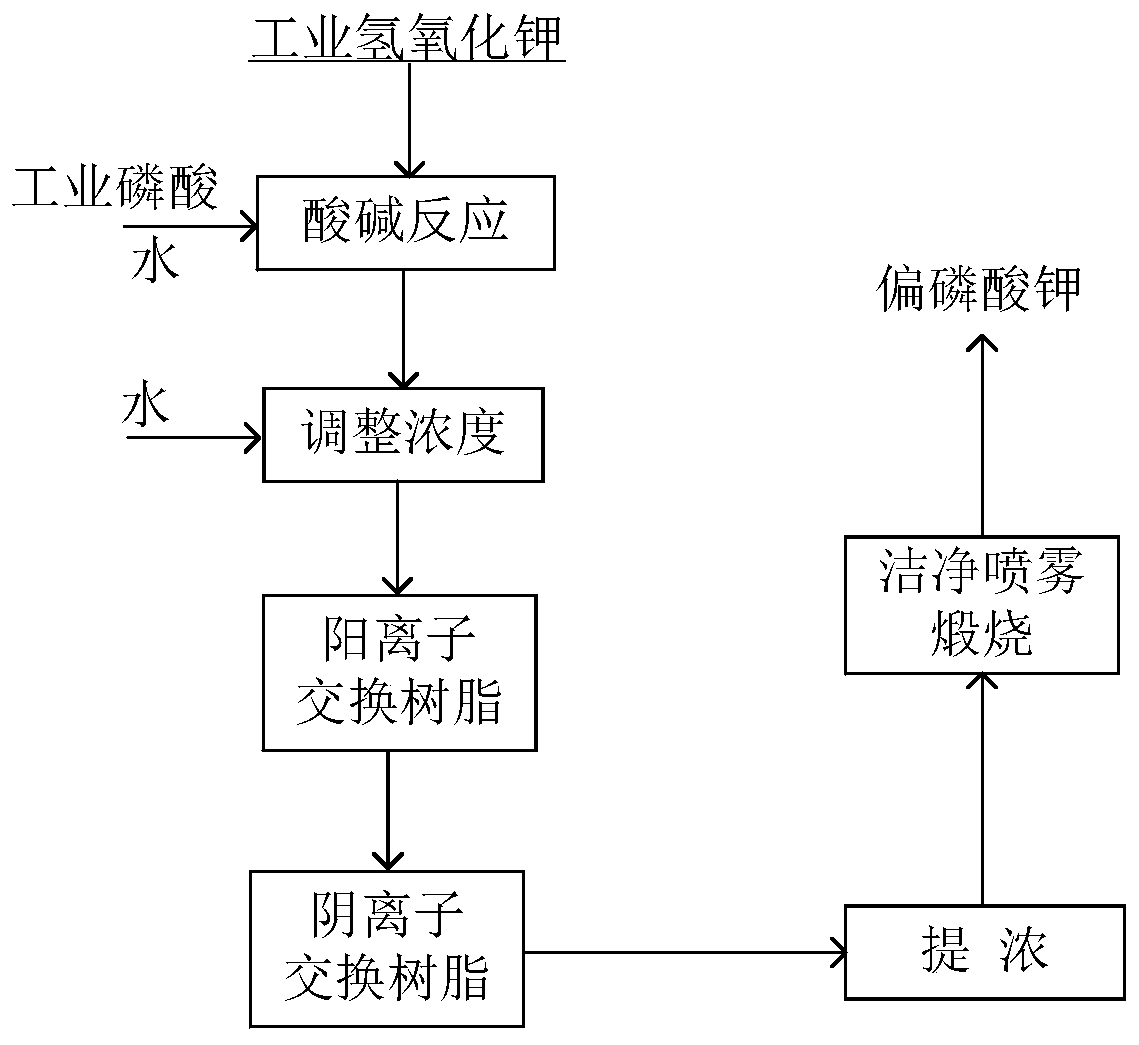

[0022] Such as figure 1 Shown, the preparation method of the optical grade potassium metaphosphate of technical scheme of the present invention comprises the steps:

[0023] (1) Potassium hydroxide, phosphoric acid and water are reacted in a certain proportion (ie figure 1 The acid-base reaction in), obtain thick potassium dihydrogen phosphate solution;

[0024] (2) adjust the concentration of described crude potassium dihydrogen phosphate solution (ie figure 1 The concentration adjustment step in the process), and pass through the ion exchange resin at a certain flow rate to remove non-ferrous metals and impurity ions;

[0025] (3) Evaporation and concentration to obtain a concentrated solution containing potassium dihydrogen phosphate at a concentration of more than 30%;

[0026] (4) dehydrate the concentrated solution (ie figure 1 In the clean spray calcination step), the removed moisture includes free water and structural water to obtain optical-grade potassium metapho...

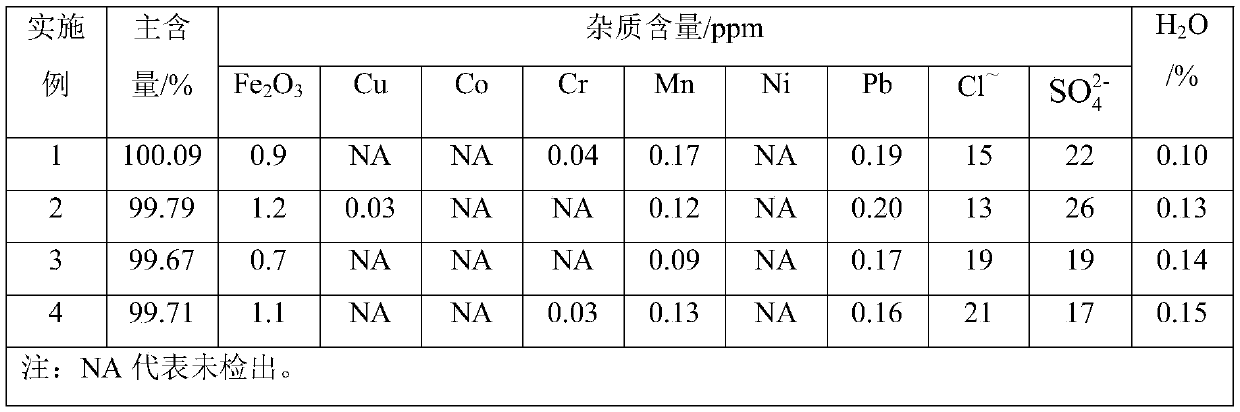

Embodiment 1

[0029] The preparation method of the optical grade potassium metaphosphate of the present embodiment specifically comprises the following steps:

[0030] (1) 100kg of industrial potassium hydroxide with a content of 97% is added to dilute phosphoric acid blended with 202.9kg of 85% industrial phosphoric acid and 487.1kg of water, and the reaction temperature is controlled at 87°C to 91°C to obtain crude dihydrogen phosphate Potassium solution;

[0031] (2) adjust the thick potassium dihydrogen phosphate solution concentration to 12%, pass through a group of cation exchange resin and anion exchange resin with the flow velocity of 3.5L / min, the cation exchange resin that the embodiment of the present invention adopts is 001 * 7, 732 type cations Exchange resin, the anion exchange resin is D202 type anion exchange resin to remove Fe, Mn, Pb, Cr, Cu, Ni, Co and other non-ferrous metals and Cl - , sulfate and other impurities;

[0032] (3) Concentrate by evaporation to obtain a c...

Embodiment 2

[0035] The preparation method of the optical grade potassium metaphosphate of the present embodiment specifically comprises the following steps:

[0036] (1) 120kg of industrial potassium hydroxide with a content of 97% is added to dilute phosphoric acid blended with 244.7kg of 85% industrial phosphoric acid and 587.3kg of water, and the reaction temperature is controlled at 85°C to 89°C to obtain crude dihydrogen phosphate Potassium solution;

[0037] (2) adjust the thick potassium dihydrogen phosphate solution concentration to 11%, pass through a group of cation exchange resin and anion exchange resin with the flow velocity of 4L / min, the cation exchange resin that the embodiment of the present invention adopts is 741 type, D001 type cation exchange resin , the anion exchange resin is D202 type, D406 type anion exchange resin to remove Fe, Mn, Pb, Cr, Cu, Ni, Co and other non-ferrous metals and Cl - , sulfate and other impurities;

[0038] (3) Concentrate by evaporation to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com