Regular structure catalyst, preparation method and application thereof, and treatment method of incomplete regeneration flue gas

A technology of regular structure and regular structure carrier, applied in catalyst activation/preparation, gas treatment, chemical instruments and methods, etc., can solve the problem of low catalytic conversion activity, achieve high catalytic conversion activity, simple preparation method, and be conducive to catalysis The effect of transforming activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

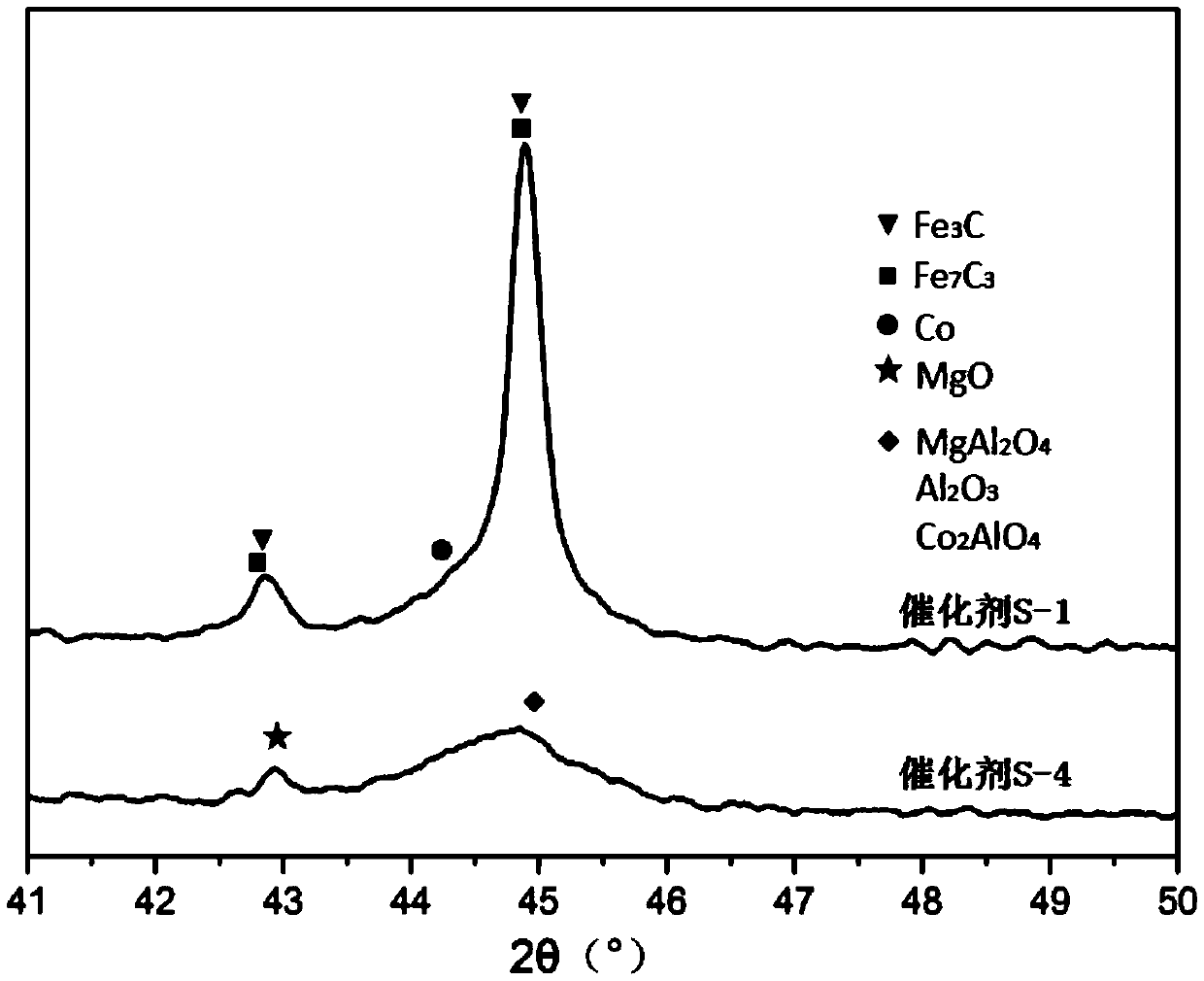

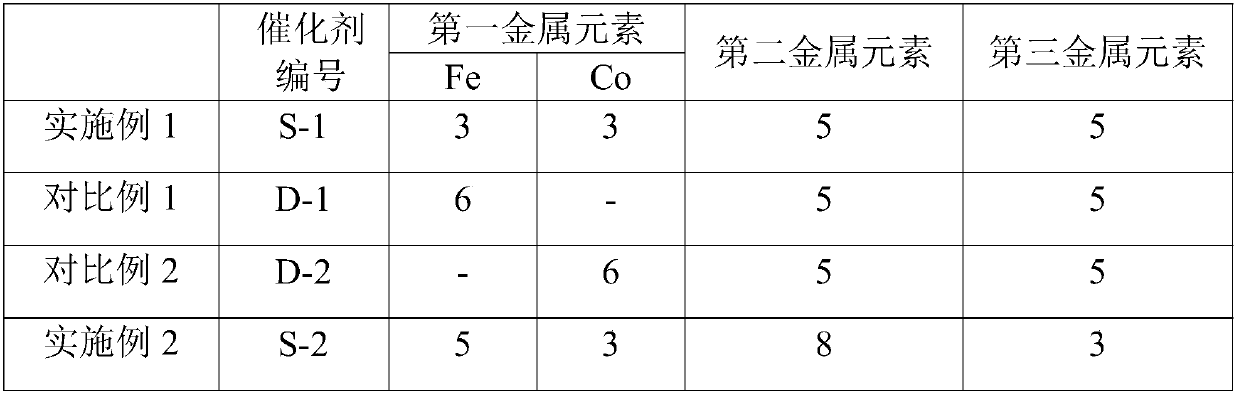

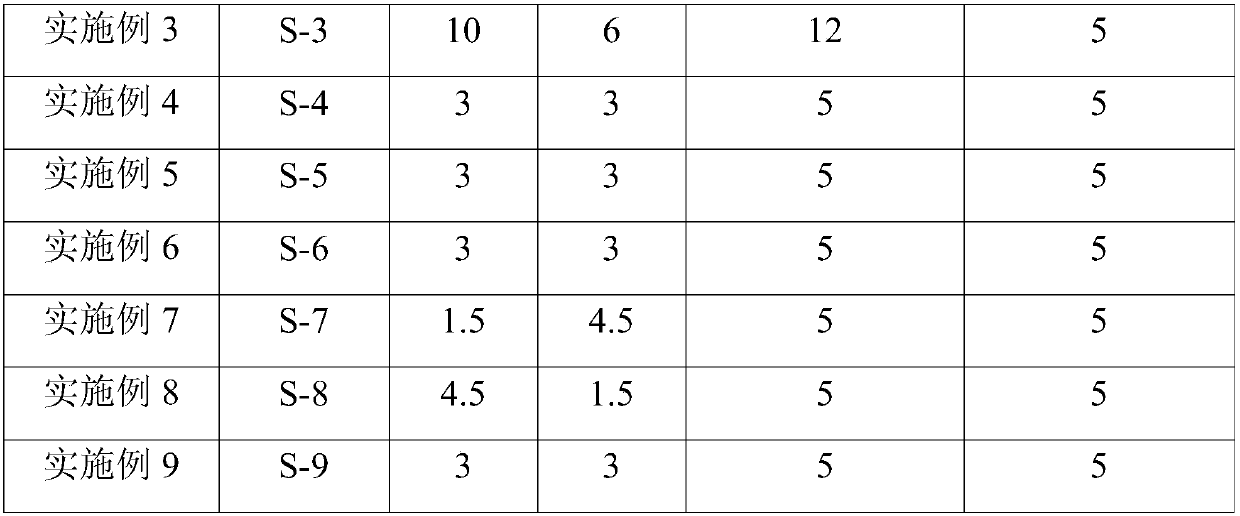

Embodiment 1

[0099] (1) Add 262g pseudo-boehmite to 1.42kg deionized water to make a slurry and disperse, then add 23.8mL hydrochloric acid to acidify for 15min to obtain bauxite colloid. The iron nitrate (as Fe 2 O 3 Calculated) 6g, cobalt nitrate (in Co 2 O 3 Count) 6g, KMnO 4 (Calculated by MnO) 10g, add 350mL water and stir until fully dissolved, add bauxite colloid to it, stir for 15min to obtain the first solution; add 10g MgO to 30g water, stir for 10min, add to the first solution, stir for 20min Afterwards, the active component coating slurry is obtained;

[0100] (2) Use the active component coating slurry obtained in step (1) to coat the cordierite honeycomb carrier (the carrier pore density is 400 pores / square inch, the cross-section opening rate is 70%, and the pore shape is square). Dry (100℃, 4h), then transfer to a tube furnace, and pass in CO / N with a CO concentration of 10% by volume at a flow rate of 100mL / min 2 The mixed gas is treated at 600°C for 1.5h to obtain a coating o...

Embodiment 2

[0105] (1) Add 253g pseudo-boehmite into 1.37kg deionized water for beating and dispersing, and then add 22.9mL hydrochloric acid to acidify for 15min to obtain bauxite colloid. The ferric nitrate (as Fe 2 O 3 Calculated) 10g, cobalt nitrate (in Co 2 O 3 Count) 6g, KMnO 4 (Calculated by MnO) 6g was added to 350mL of water and stirred until fully dissolved, the bauxite colloid was added to it, stirred for 15min to obtain the first solution; 16g MgO was added to 48g of water, stirred for 10min, then added to the first solution, stirred for 20min , Obtain the active component coating slurry;

[0106] (2) Use the active component coating slurry obtained in step (1) to coat the cordierite honeycomb carrier (the carrier pore density is 400 pores / square inch, the cross-section opening rate is 70%, and the pore shape is square). Dry (100℃, 4h), then transfer to a tube furnace, and pass in CO / N with a CO concentration of 10% by volume at a flow rate of 100mL / min 2 The mixed gas was treated...

Embodiment 3

[0110] (1) Add 209g pseudo-boehmite into 1.13kg deionized water to make a slurry and disperse, and then add 19.0mL hydrochloric acid to acidify for 15min to obtain bauxite colloid. The iron nitrate (as Fe 2 O 3 Calculated) 20g, cobalt nitrate (in Co 2 O 3 Total) 12g, KMnO 4 (Calculated by MnO) add 10g into 350mL water and stir until fully dissolved, add bauxite colloid to it, stir for 15min to obtain the first solution; add 24g MgO to 72g water, stir for 10min, add to the first solution, stir for 20min , Obtain the active component coating slurry;

[0111] (2) Use the active component coating slurry obtained in step (1) to coat the cordierite honeycomb carrier (the carrier pore density is 400 pores / square inch, the cross-section opening rate is 70%, and the pore shape is square). Dry (100℃, 4h), then transfer to a tube furnace, and pass in CO / N with a CO concentration of 10% by volume at a flow rate of 100mL / min 2 The mixed gas is treated at 650°C for 1 hour to obtain a coating of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com