A Treatment Method for Incompletely Regenerated Flue Gas

A complete regeneration, flue gas technology, applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve the problem of low catalytic conversion activity, and achieve the effect of reducing NOx emission and improving catalytic conversion activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

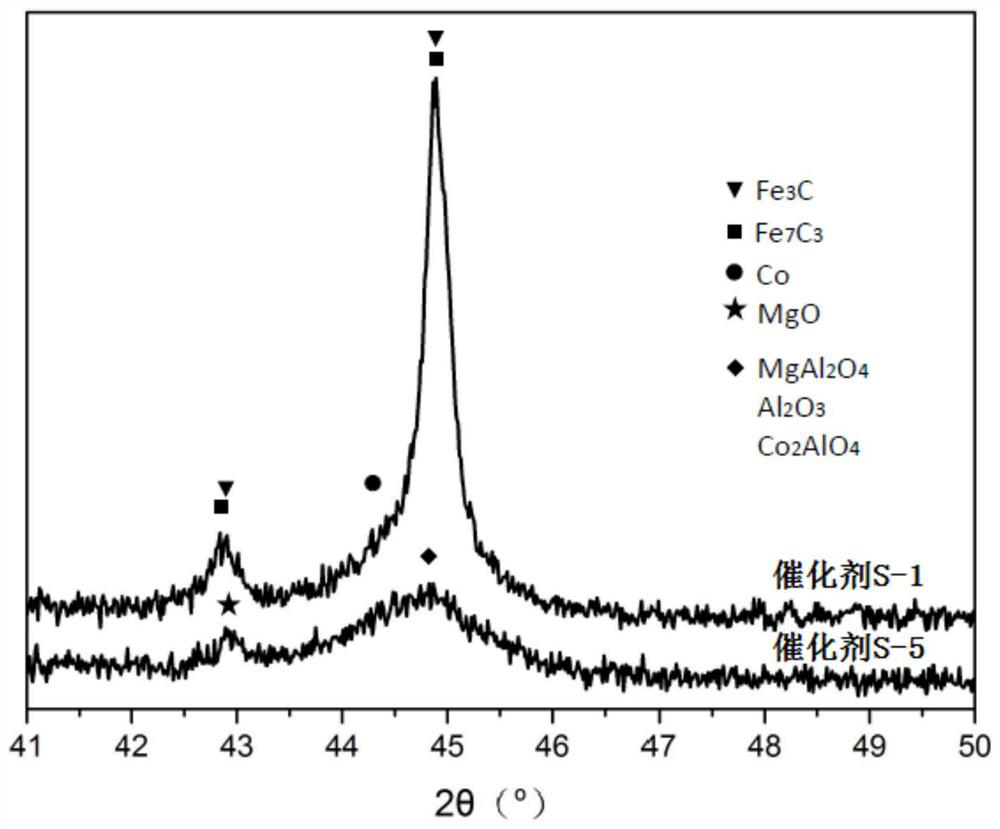

Image

Examples

preparation example Construction

[0055] The present invention has no special limitation on the preparation method of the regular structure catalyst, as long as the regular structure catalyst with the above-mentioned composition and structural characteristics can be obtained, it can be used in the present invention. Preferably, the preparation method of the regular structure catalyst includes:

[0056] Option One:

[0057] (1) mixing and beating the matrix source, the first metal element precursor, the second metal element precursor and water to obtain the active component coating slurry;

[0058] (2) Coating the structured structure carrier with the active component coating slurry and drying and first roasting to obtain the active component coating distributed on the inner surface and / or outer surface of the regular structure carrier;

[0059] or

[0060] Option II:

[0061] a) mixing and beating the matrix source, the first metal element precursor and water to obtain the first slurry;

[0062] b) coating ...

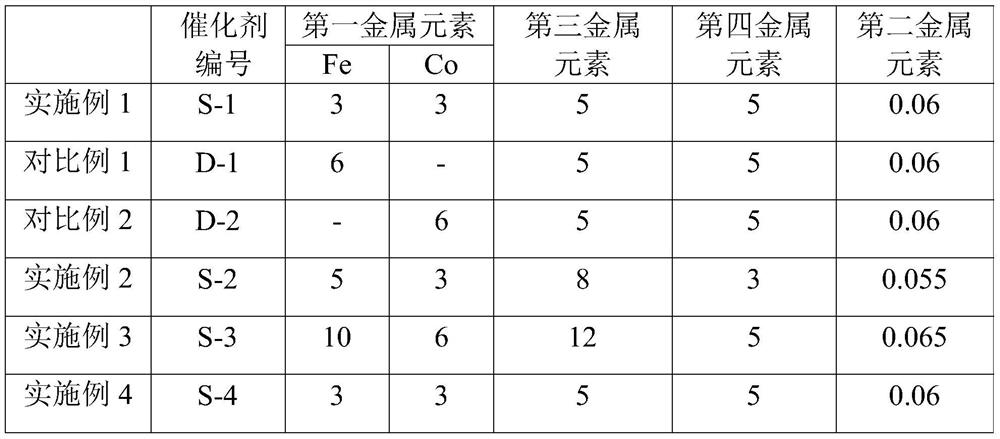

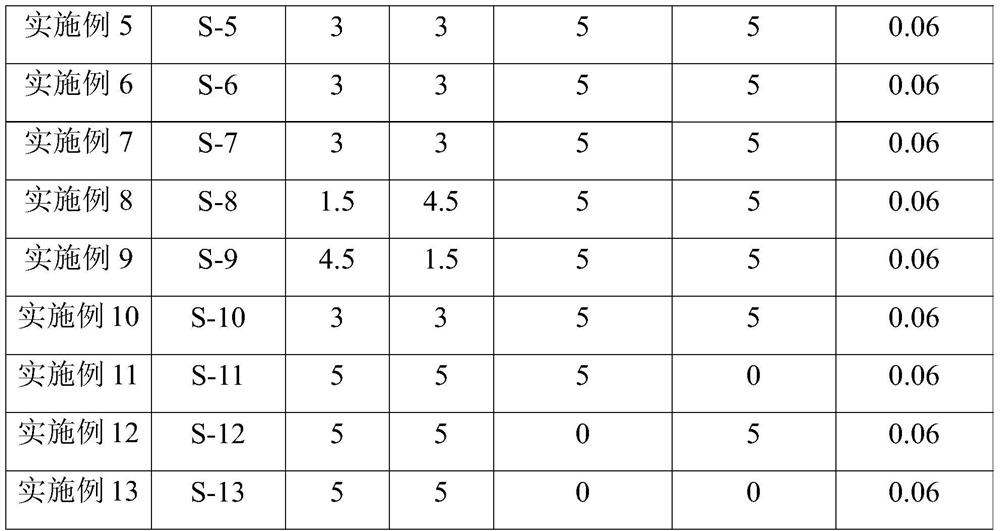

Embodiment 1

[0101] (1) 262g of pseudo-boehmite was added into 1.42kg of deionized water for beating and dispersion, then 23.8mL of hydrochloric acid was added for acidification for 15min to obtain the bauxite colloid, and ferric nitrate (calculated as Fe) 2 o 3 Count) 6g, cobalt nitrate (as Co 2 o 3 Count) 6g, KMnO 4 (as MnO) 10g, RuCl with a mass content of 12.5g / L in terms of metal elements 3 Add 9.6mL of the solution into 350mL of water and stir until it is fully dissolved, add bauxite colloid to it, and stir for 15min to obtain the first solution; add 10g of MgO to 30g of water, stir for 10min, then add it to the first solution, and stir for 20min to obtain the active Component coating slurries;

[0102] (2) The active component coating slurry obtained in step (1) is used to coat the cordierite honeycomb carrier (the carrier pore density is 400 holes / square inch, the opening rate of the cross section is 70%, and the shape of the hole is a square), after Dry (100°C, 4h), then tran...

Embodiment 2

[0107] (1) 253g of pseudo-boehmite was added into 1.37kg of deionized water for beating and dispersion, then 22.9mL of hydrochloric acid was added for acidification for 15min to obtain the bauxite colloid, and ferric nitrate (calculated as Fe) 2 o 3 Count) 10g, cobalt nitrate (as Co 2 o 3 Count) 6g, KMnO 4 (as MnO) 6g, RuCl with a mass content of 12.5g / L in terms of metal elements 3 Add 8.8mL of the solution into 350mL of water and stir until it is fully dissolved, add bauxite colloid to it, and stir for 15min to obtain the first solution; add 16g of MgO to 48g of water, stir for 10min, then add it to the first solution, and stir for 20min to obtain the active Component coating slurries;

[0108] (2) The active component coating slurry obtained in step (1) is used to coat the cordierite honeycomb carrier (the carrier pore density is 400 holes / square inch, the opening rate of the cross section is 70%, and the shape of the hole is a square), after Dry (100°C, 4h), then tran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com