Composition capable of reducing CO and NOx emission, preparation method and application thereof, and fluid catalytic cracking method

A composition and catalyst technology, which is applied in catalytic cracking, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of low catalytic conversion activity and achieve high catalytic conversion activity and production The effect of low cost and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0043] According to a preferred embodiment of the present invention, the inorganic oxide carrier is at least one selected from alumina, spinel and perovskite, more preferably alumina.

[0044] In the present invention, the alumina can be selected from at least one of γ-alumina, δ-alumina, η-alumina, ρ-alumina, κ-alumina and χ-alumina, and the present invention There is no particular limitation.

[0045] The alumina may be derived from various sols or gels of aluminum, or aluminum hydroxide. The aluminum hydroxide may be selected from at least one of gibbsite, pyrenite, diaspore, diaspore, boehmite and pseudoboehmite. Preferably the alumina is derived from pseudoboehmite.

[0046] The above-mentioned inorganic oxide supports are commercially available, and can also be prepared by existing methods.

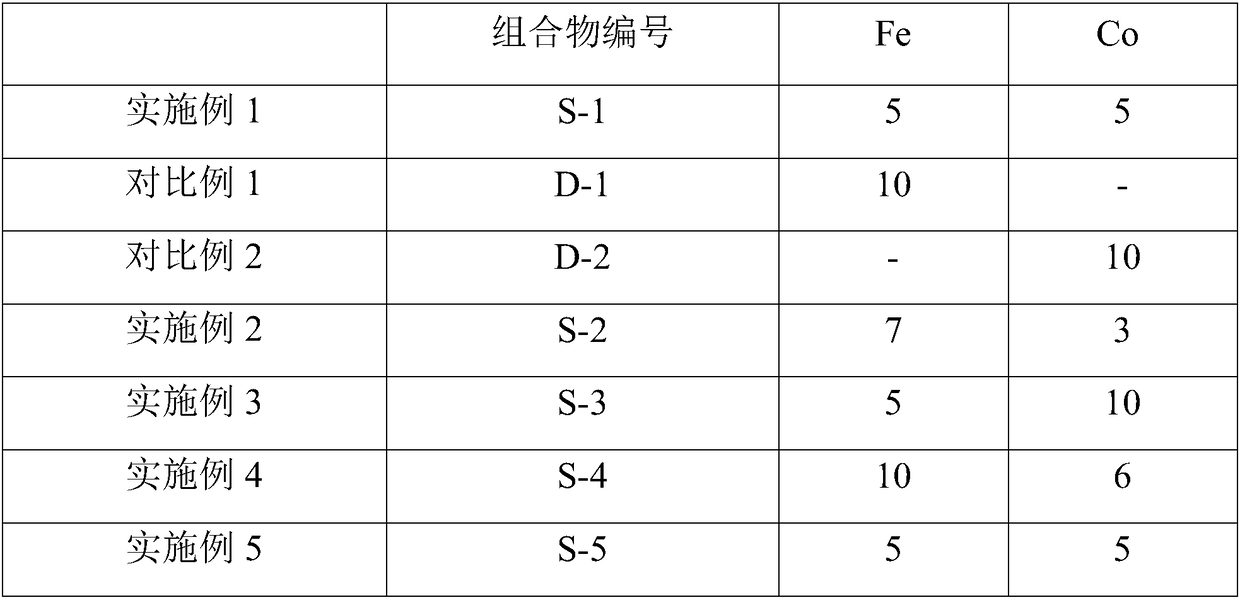

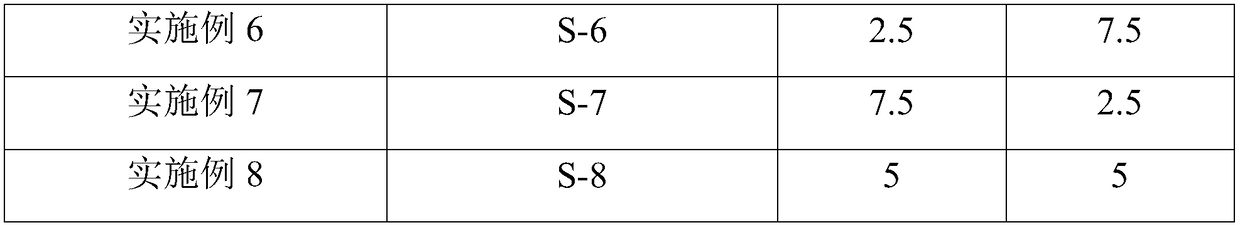

[0047] According to a most preferred embodiment of the present invention, with specific content Fe, Co are used as metal elements, can greatly improve the composition that can re...

Embodiment 1

[0092] (1) 2.62kg of pseudo-boehmite is added to 14.2kg of deionized water for beating and dispersion, then 238mL of hydrochloric acid is added for acidification for 15min to obtain the bauxite colloid, and ferric nitrate (calculated as Fe) 2 o 3 meter, the same below) 100g, cobalt nitrate (in Co 2 o 3 Add 100g of bauxite colloid, the same below) into 3500mL of water and stir until it is fully dissolved, then add bauxite colloid and stir for 20min to obtain a slurry, spray dry the slurry, and take 100g of spray-dried particles (average particle diameter is 65μm, particle particles with a diameter of 40-80 μm accounted for 60%, the same below) were transferred to the tube furnace, and CO / N with a CO concentration of 10% by volume was fed at a flow rate of 100mL / min. 2 The mixed gas was treated at 600°C for 1.5h to obtain composition S-1.

[0093] The content determination results of each component in composition S-1 are listed in Table 1.

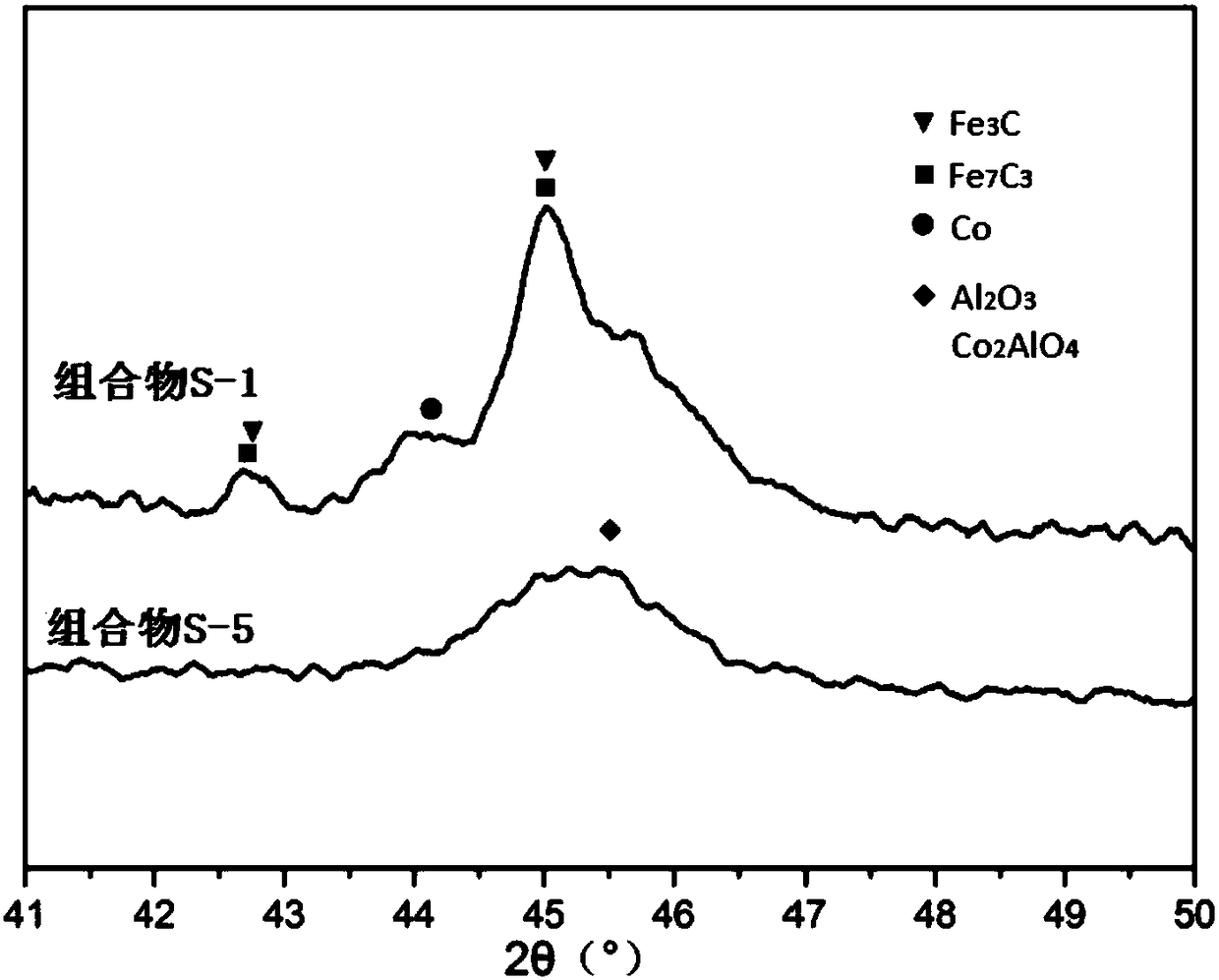

[0094] Carry out XRD analysis to ...

Embodiment 2

[0098] (1) Add 2.56kg of pseudoboehmite to 13.9kg of deionized water for beating and dispersing, then add 232mL of hydrochloric acid to acidify for 15min to obtain bauxite colloid, add 140g of iron nitrate and 60g of cobalt nitrate calculated as metal oxides into 3500mL of water Stir until fully dissolved, add the bauxite colloid, stir for 20 minutes to obtain a slurry, spray dry the slurry, transfer 100 g of the spray-dried particles to a tube furnace, and feed the CO concentration at a flow rate of 100mL / min 10% by volume CO / N 2 Mixed gas and treated at 500°C for 3 hours to obtain composition S-2.

[0099] The content determination results of each component in the composition S-2 are listed in Table 1. The XRD analysis result of composition S-2 is similar to that of Example 1. In the XRD spectrum of the composition S-2 treated with a carbon-containing atmosphere, there is not only Al at about 45.5° 2 o 3 and Co 2 AlO 4 , and there are obvious diffraction peaks at about...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com