Composition capable of reducing CO and NOx emission, preparation method and application thereof, and fluid catalytic cracking method

A composition and oxide technology, used in catalytic cracking, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of low catalytic conversion activity and achieve high catalytic conversion activity, Simple preparation method and the effect of reducing CO and NOx emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a method for preparing a composition capable of reducing CO and NOx emissions, the method comprising:

[0030] (1) mixing and beating the precursor of the inorganic oxide carrier, the precursor of the first metal element and water to obtain a slurry, spray-drying the slurry, and then performing the first roasting to obtain a semi-finished composition;

[0031] (2) Using the solution containing the precursor of the fourth metal element as the impregnating solution, the semi-finished composition obtained in step (1) is impregnated to obtain a solid product, and the solid product is subjected to alkali treatment, and then dried and / or the second Roasting;

[0032] Wherein, the first metal element is selected from Group VIII non-noble metal elements, and the first metal element includes Fe and Co; the fourth metal element is selected from at least one of noble metal elements;

[0033] Wherein, in the precursor of the first metal element, the amount o...

Embodiment approach

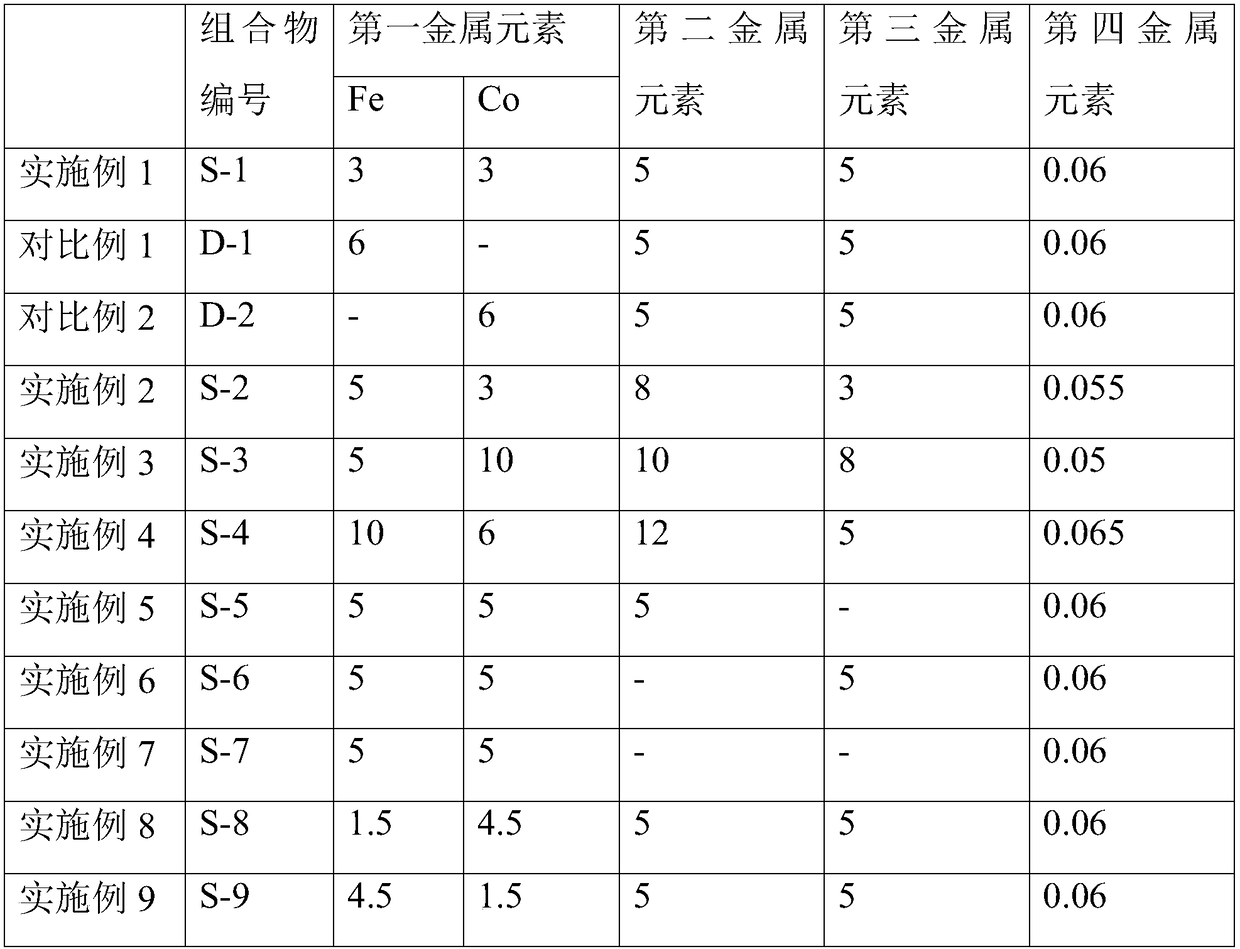

[0053] According to a preferred embodiment of the present invention, the method also includes: introducing a second metal element precursor and / or a third metal element precursor in the mixing and beating process described in step (1); From at least one of Group IA and / or Group IIA metal elements, the third metal element is selected from at least one of Group IB-VIIB non-noble metal elements.

[0054] Introducing the second metal precursor in the beating process can improve the performance of the composition, and introducing the third metal precursor in the beating process can also improve the performance of the composition, but at the same time introducing the second metal element precursor and the third metal element precursor The body is more conducive to further improving the performance of the composition.

[0055] Therefore, according to the preparation method of the present invention, in step (1), preferably, the precursor of the inorganic oxide carrier, the first metal...

Embodiment 1

[0101] (1) 2.62kg of pseudo-boehmite is added to 14.2kg of deionized water for beating and dispersion, then 238mL of hydrochloric acid is added for acidification for 15min to obtain the bauxite colloid, and ferric nitrate (calculated as Fe) 2 o 3 Count, the same below) 60g, cobalt nitrate (as Co 2 o 3 meter, the same below) 60g, KMnO 4 (calculated as MnO, the same below) 100g was added into 3500mL water and stirred until it was fully dissolved, then the bauxite colloid was added into it, and stirred for 15 minutes to obtain the first solution; 100g of MgO was added to 300g of water, stirred for 10 minutes, then added to the first solution, stirred After 20 minutes, the slurry was obtained, and the slurry was spray-dried, and 150 g of particles obtained by spray drying (the average particle diameter was 65 μm, and the particles with a particle diameter of 40-80 μm accounted for 60%, the same below) were transferred to a tube furnace, Air was introduced at a flow rate of 100m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com