Fault early warning method based on industrial process operation state trend analysis

A technology for operating states and industrial processes, applied in the fields of instruments, character and pattern recognition, computer parts, etc., it can solve the problems of insufficient robustness of data prediction in different time series processes, a large number of training samples of neural network methods, and difficulty of support vector regression. , to achieve more intuitive and reliable industrial process fault warning information, improve monitoring efficiency, and meet timeliness requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

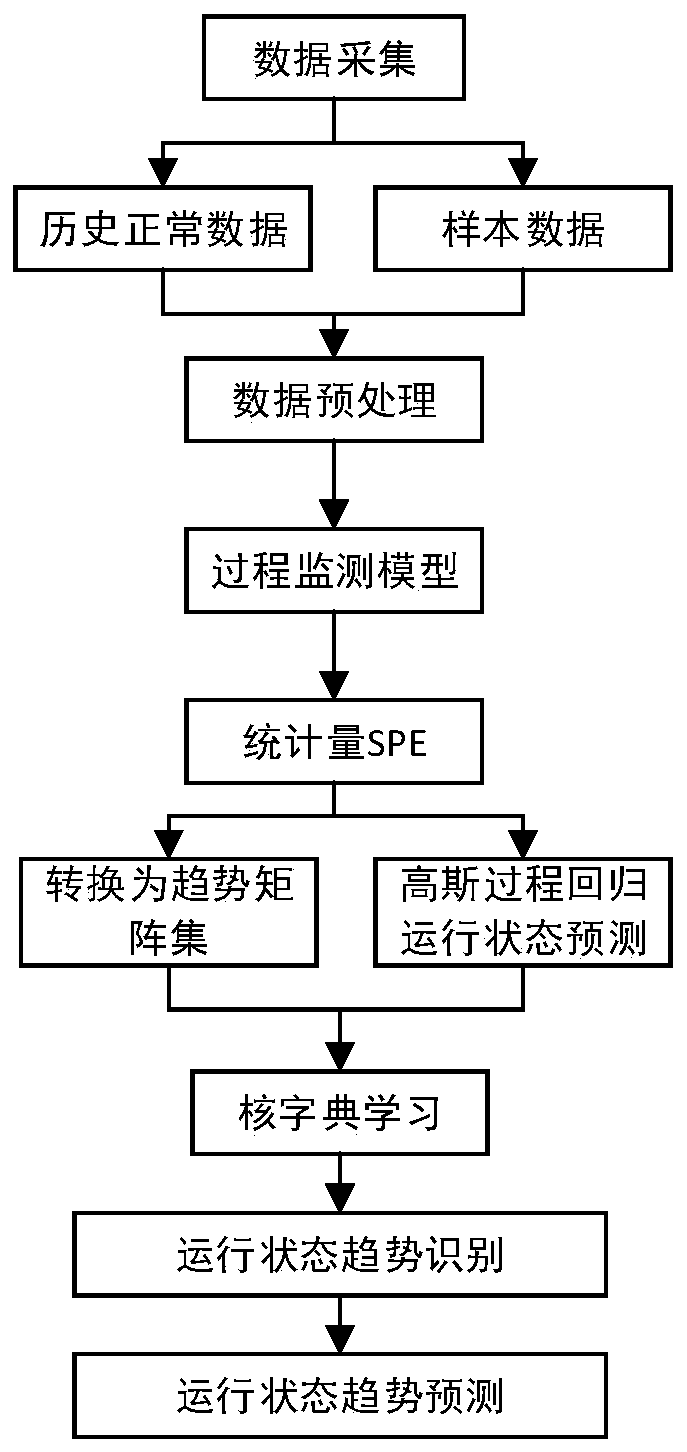

[0040] as attached figure 1 and 2 A fault early warning method based on trend analysis of industrial process operation status is shown, which is a fault trend prediction method based on Gaussian process regression and kernel dictionary learning. The present invention adopts following technical scheme:

[0041] (1) Based on the process data sensor acquisition system on the industrial site, obtain the historical normal process data sample set X and the process data sample set S with faults in the industrial process;

[0042] (2) Build a fault monitoring model through the sample set X, and then monitor the sample set S to obtain the value of the fault data monitoring statistic SPE, which is used as the observation vector Y to describe the operating state of the system;

[0043] (3) Construct a Gaussian process regression model for the sample set S and the observation vector Y;

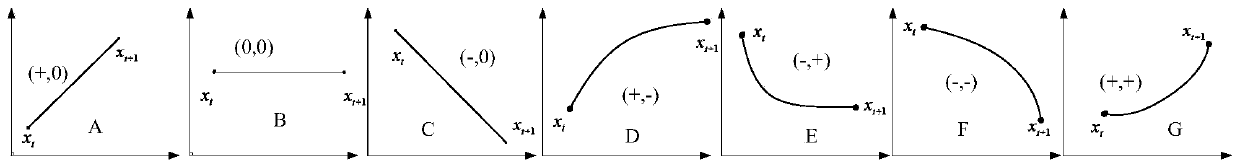

[0044] (4) Extract 7 basic trends in the sample data set S through kernel dictionary learning, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com