Photo-fuel cell sensor based on anode light induction and pollutant analysis method

A fuel cell and sensor technology, applied in the direction of material analysis, material analysis, and material electrochemical variables through electromagnetic means, can solve the problems of stability and reproducibility, output power drop, detection signal change, etc., to achieve stability Good, accelerated transfer rate, high output power effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A self-powered sensor for atrazine was prepared as follows:

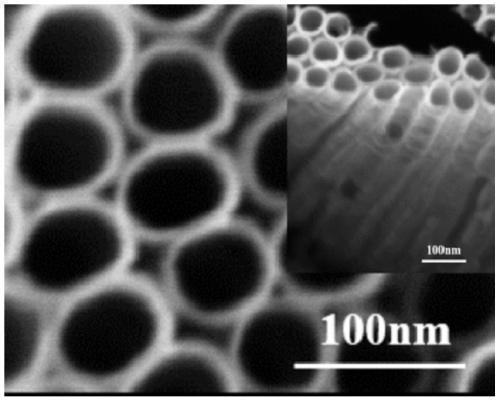

[0045] (1) Preparation of Ti-Fe-O NTs substrate electrode. First, the Ti-Fe alloy plate (the content of iron is 6wt%) with a size of 30×10×1 mm was polished to a smooth surface using 180#, 320#, 600# and metallographic sandpaper in sequence. Then ultrasonically clean with acetone, absolute ethanol, and high-purity water for 10 minutes, and dry naturally for later use. Secondly, at room temperature, the Ti-Fe alloy plate was used as the anode, placed in the 4 F and 2wt%H 2 In the ethylene glycol solution of O, the platinum plate electrode was used as the cathode, and the distance between the electrodes was 1 cm. Under the condition of stirring at a rotational speed of 100r / min, a DC power supply was used to apply a voltage of 30V to carry out anodic oxidation for 3h, and then the electrode was taken out, and the residual electrolyte on the surface was washed with high-purity water. Finally, it was placed i...

Embodiment 2

[0057] Adopt the self-powered sensor prepared in embodiment 1 to measure the ATZ of different concentrations:

[0058] Atrazine solutions with a series of concentrations were prepared with PBS (PH=7) buffer solution: 0 nM, 0.01 nM, 0.1 nM, 0.5 nM, 1 nM, 5 nM, 10 nM, 50 nM, 100 nM. Incubate the cathode GCE / G / MIP with a series of concentrations of ATZ sequentially, each incubation time is 10min. Under the anodic extreme condition of visible light irradiation, the OCP-T of the self-powered sensor at different concentrations was measured. Through the analysis results, it was found that within a certain concentration range, as the concentration of atrazine increased, the OCP decreased. When the OCP measured by the self-powered sensor was 792mV under blank conditions, the OCP value of the sensor dropped to 785mV after incubation with 0.01nMATZ. After further incubation with 0.1nM ATZ, the OCP value of the sensor dropped to 781mV. This is due to the specific binding of atrazine to...

Embodiment 3

[0060] Adopt the self-powered sensor prepared by embodiment 1 to carry out selective determination:

[0061] Add 8.00mL of 100mM NaOH solution (containing 50mM glucose solution) and 8.00mL of 10mM potassium ferricyanide solution into the anode chamber and the cathode chamber respectively. With the prepared anode Ti-Fe-O NTs / Ni(OH) 2 It is placed in the anode chamber, and the prepared cathode GCE / G / MIP is placed in the cathode chamber. Under the condition of excitation light, the OCP of the self-powered sensor is measured by OCPT technique. GCE / G / MIP was used to incubate 1nM ATZ solution, followed by incubation with 100 times the concentration of interfering substances: hemoglobin, paraquat, monosultap, and acetamiprid, and their OCPs were determined respectively. The relative ratio (R%) of the associated open-circuit voltage was calculated to obtain the selectivity of the self-powered sensor. The results showed that when hemoglobin and acetamiprid contained 100 times the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com