Water-soluble toilet paper and preparation process thereof

A preparation process and technology for toilet paper, applied in the field of toilet paper preparation, can solve the problems of toilet blockage and long time, and achieve the effects of increasing concentration, good and rapid dissociation, and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

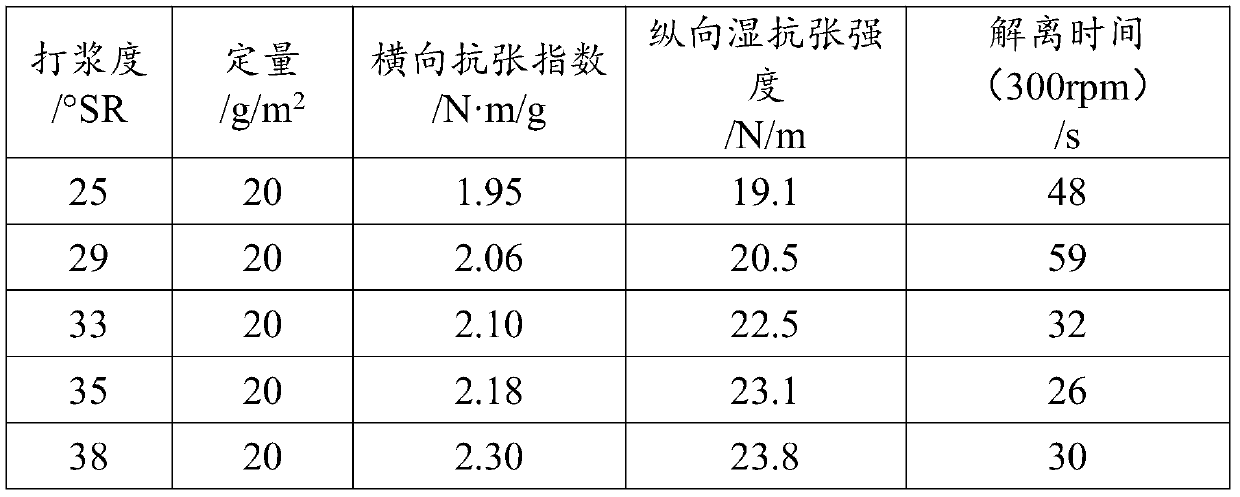

[0033] A kind of preparation technology of water-soluble toilet paper, specifically comprises the steps:

[0034] (1) After mixing the mixed bleached wood pulp and sodium carboxymethyl cellulose, it is disintegrated and beaten to obtain a mixed slurry;

[0035] (2) Screening and purifying the mixed slurry obtained in step (1), followed by slow-speed papermaking and pressing to obtain paper sheets;

[0036] (3) Alkali treatment is carried out on the paper sheet obtained in step (2) with weakly alkaline sodium salt, followed by drying and rolling to obtain water-soluble toilet paper.

[0037] In order to further optimize the above-mentioned technical scheme, the mixed bleached wood pulp in step (1) is a mixture of bleached softwood pulp and bleached hardwood pulp according to the following mass ratio: bleached softwood pulp 10% to 30%, bleached hardwood pulp 70% %~90%.

[0038] In order to further optimize the above-mentioned technical scheme, the mass ratio of sodium carboxym...

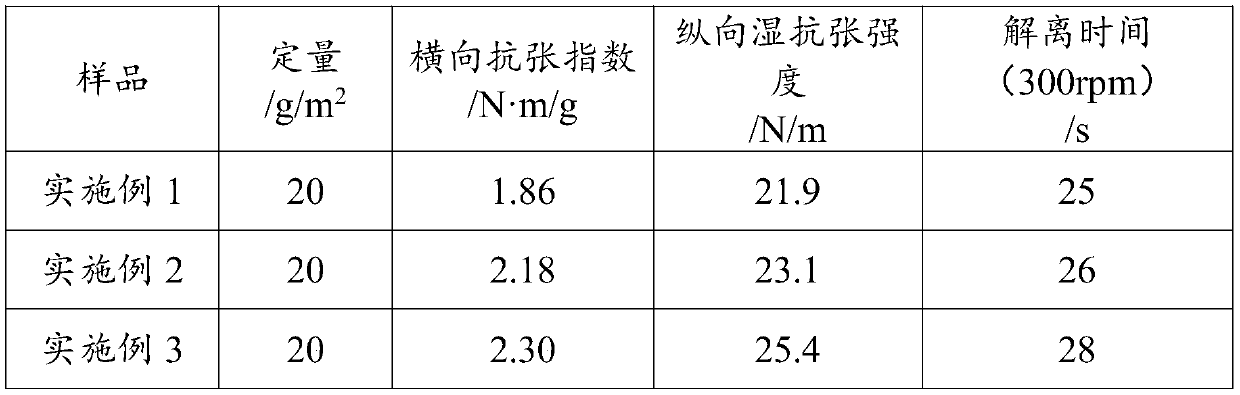

Embodiment 1

[0043] A kind of preparation technology of water-soluble toilet paper, concrete steps are as follows:

[0044] The ratio of bleached softwood pulp and bleached hardwood pulp in the mixed bleached wood pulp is 1:9, the amount of sodium carboxymethyl cellulose is 30% of the mixed bleached wood pulp, and the mixed bleached wood pulp and CMC are mixed and beaten in a beater The degree of beating is 33°SR, and it is slowly copied and pressed on the paper machine; finally, the paper is treated with alkaline sodium salt, and the concentration of lye is 10%, and then dried and rolled to obtain water-soluble toilet paper .

Embodiment 2

[0046] A kind of preparation technology of water-soluble toilet paper, concrete steps are as follows:

[0047] The ratio of bleached softwood pulp and bleached hardwood pulp in the mixed bleached wood pulp is 2:8, the amount of sodium carboxymethyl cellulose is 33% of the mixed bleached wood pulp, and the mixed bleached wood pulp and CMC are mixed and beaten in a beater The degree of beating is 35°SR, and it is slowly copied and pressed on the paper machine; finally, the paper is treated with alkali with a weak alkaline sodium salt, and the concentration of the lye is 11%, and then dried and rolled to obtain water-soluble toilet paper .

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com