Production process of velvet containing spiral pile

A production process and spiral technology, which is applied to the production process field containing spiral pile velvet, can solve the problems of incompatibility, weak fluff, environmental pollution, etc. elastic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

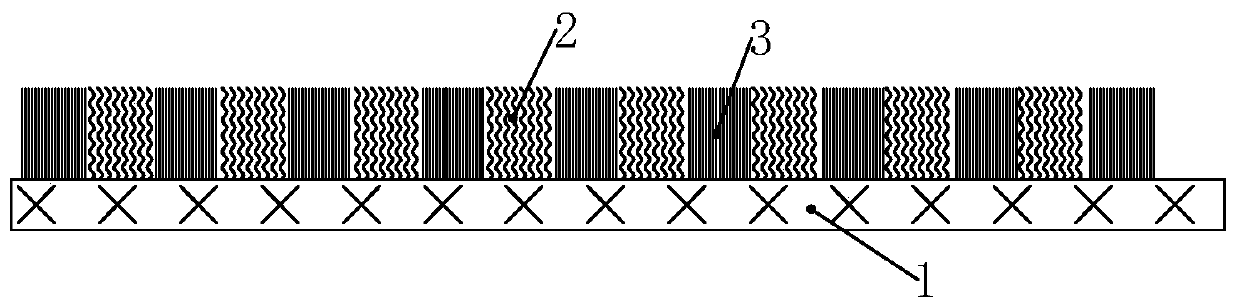

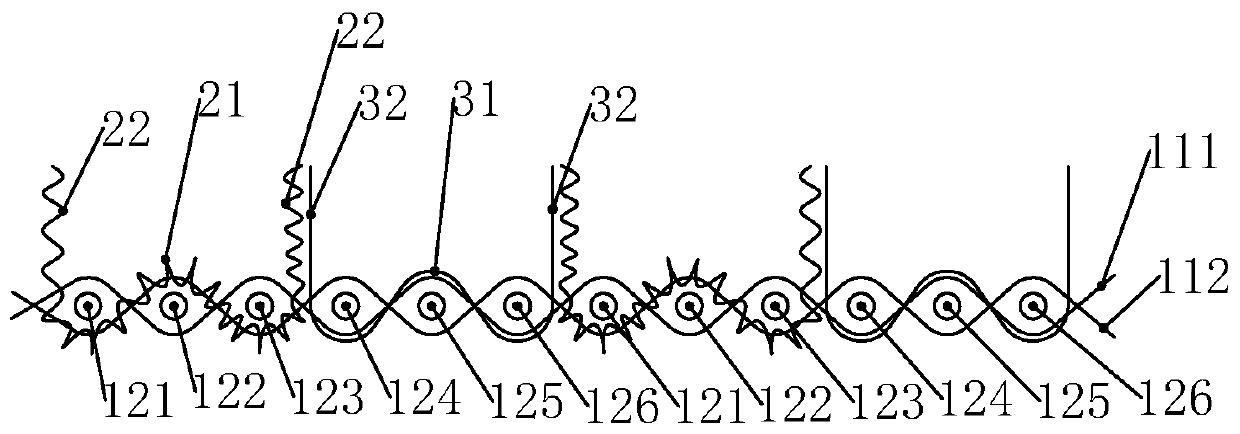

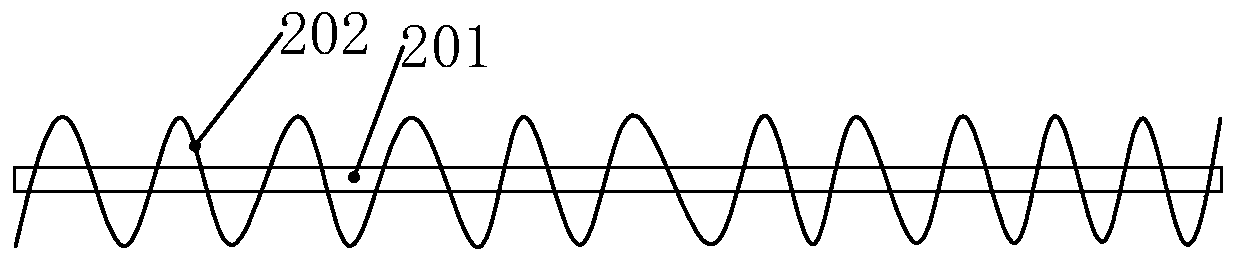

[0030] combine Figure 1 to Figure 3 , to describe this embodiment in detail. The velvet with spiral pile involved in this embodiment includes base fabric 1 and pile. The base fabric 1 is formed by interweaving ground warp yarns and ground weft yarns, and the fluff includes a consolidated portion fixed to the base fabric and piles protruding from the base fabric. The consolidation part and the ground weft yarn are consolidated in V-shape or W-shape. The villi include spiral villi. Further, fluff also includes conventional fluff formed by conventional yarns. The spiral piles form the spiral pile region, and the regular piles form the regular pile region. The spiral pile area and the conventional pile area cooperate in a certain order to form a pattern. The spiral pile 2 and the base cloth 1 are consolidated through the spiral pile through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com