High-density micro-nano coil flexible heterogeneous integration method

A micro-nano and coil technology, applied in the field of micro-electromechanical system technology and micro-energy collection, can solve the problems of complex engraving process, non-conformal assembly, impracticality, etc., and achieve the effect of expanding the application range and enhancing the adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The idea, specific structure and technical effects of the present application will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present application.

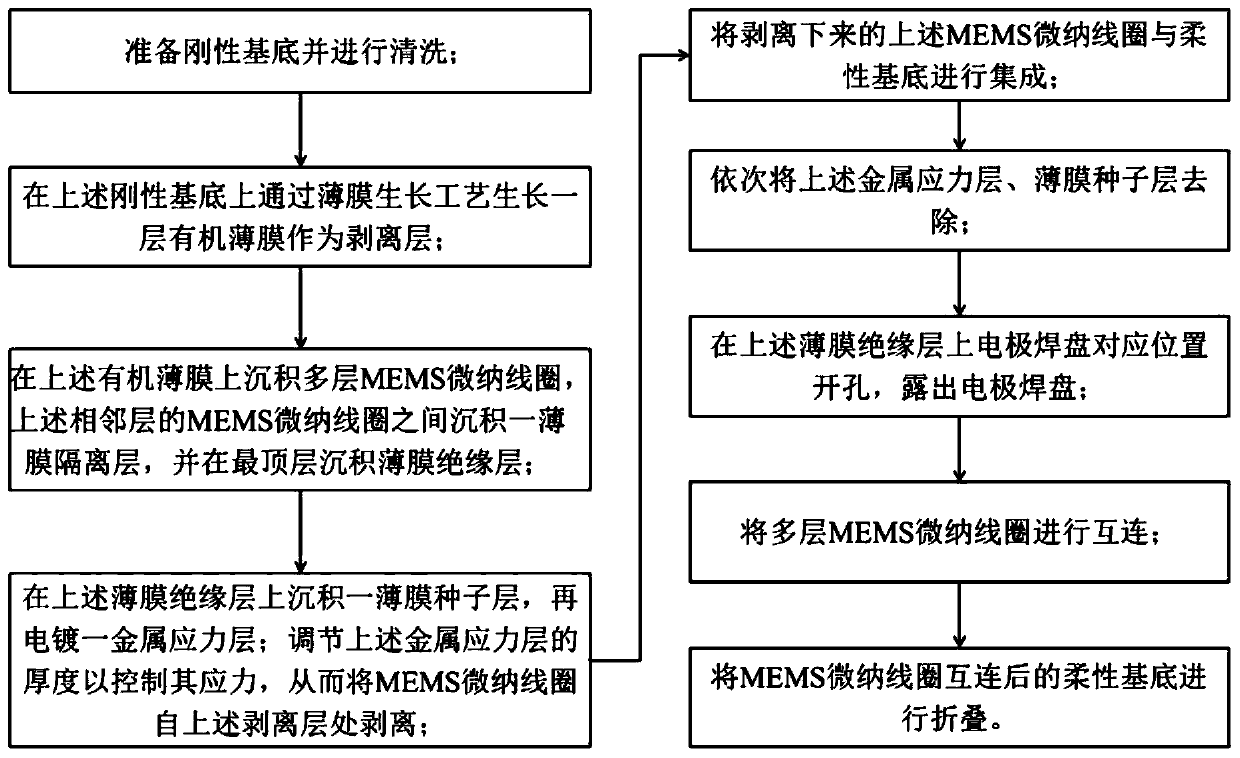

[0050] Such as figure 1 As shown, in one of the embodiments of the present application, a method for flexible heterogeneous integration of high-density MEMS micro-nano coils, the method includes the following steps:

[0051] Step 1, preparing the rigid base 1 and cleaning it.

[0052] Wherein, in this embodiment, the above-mentioned rigid substrate 1 can adopt silicon wafer or glass, etc., such as figure 2 shown.

[0053] Specifically, in this embodiment, a four-inch, double-sided polished clean silicon wafer or glass can be prepared.

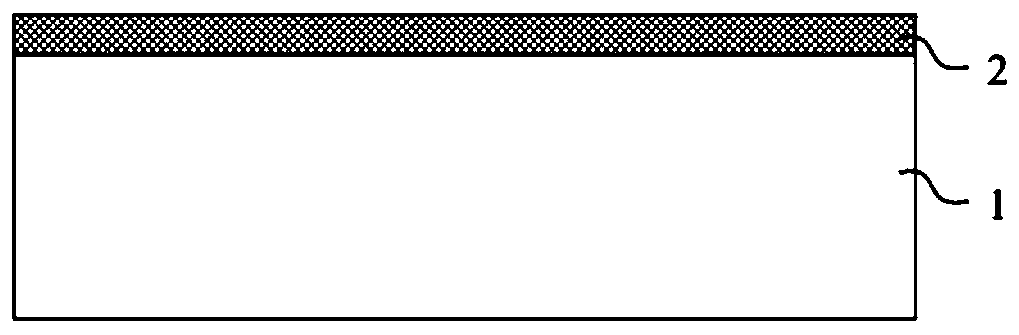

[0054] Step 2, grow a peeling layer 2 on the rigid substrate 1 through a thin film growth process, such as image 3 shown.

[0055] Wherein, the film growth process includes: chemical vapo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com