Continuous casting roller driving roller shaft spline repairing method

A repair method and continuous casting roll technology, which is applied in the field of spline repair and can solve problems such as scrapping of driving rolls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

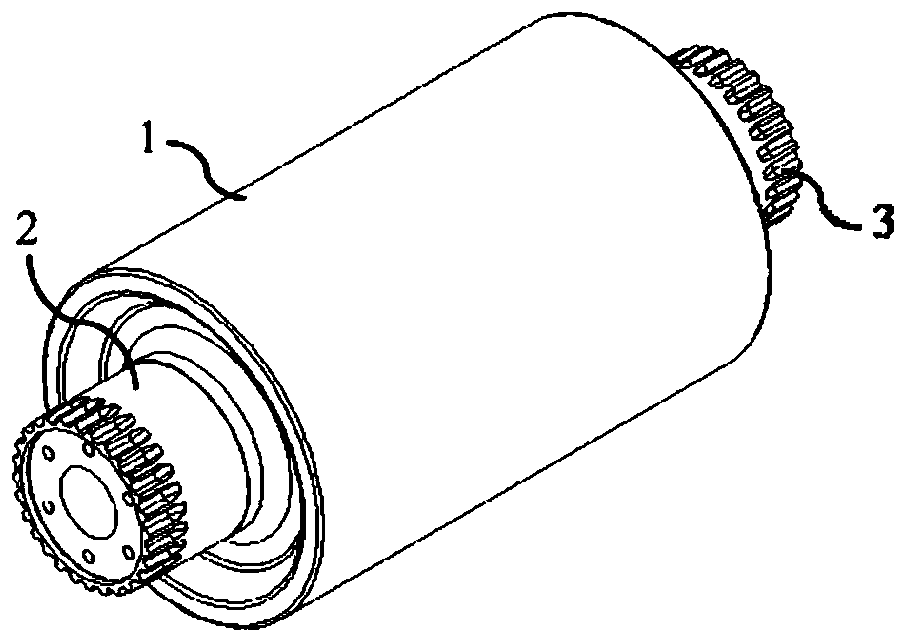

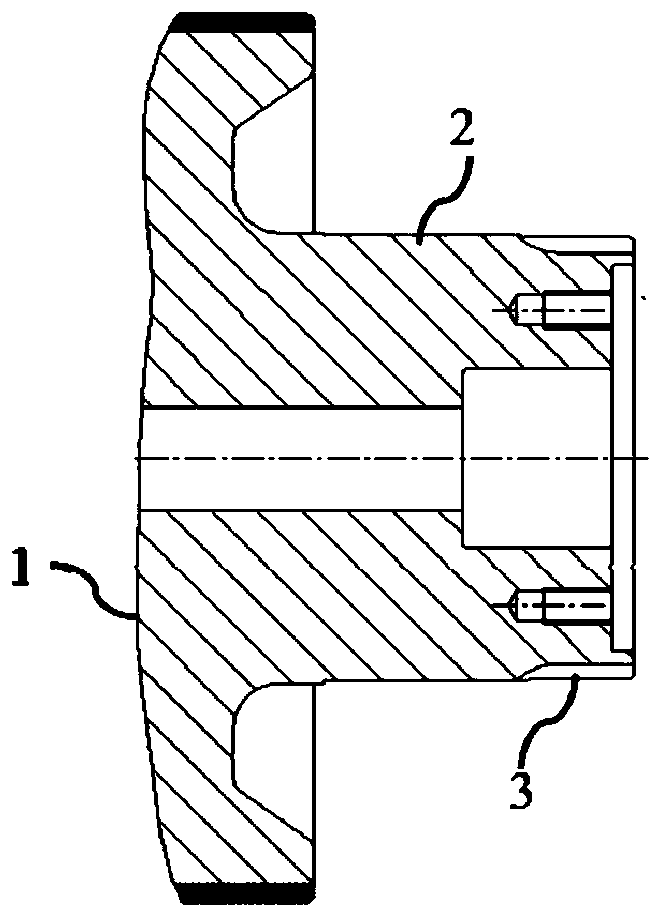

[0050] A method for repairing the spline of the continuous casting roll driving roll shaft in this embodiment, such as Figure 1-2 shown, including the following steps:

[0051] Step 1. Finite element analysis: Simulate the meshing force of the spline, and analyze the distance between the strain generated by the stress and the root of the tooth, so as to determine the length of the old spline tooth removed before welding;

[0052]Step 2. Preheating: Since the material of the continuous casting roll is prone to defects such as cracks, the workpiece is preheated before submerged arc automatic welding. The heating rate is 30-50°C / h, preheated to 250-350°C, and kept 1-2h. During local welding, local preheating treatment can be carried out with the torch flame on the repair welding place and its surrounding area of 75mm;

[0053] Step 3. Clean up the repaired welding surface: Thoroughly clean the repaired welding surface and the rust and other dirt within 25mm nearby;

[0054]...

Embodiment 2

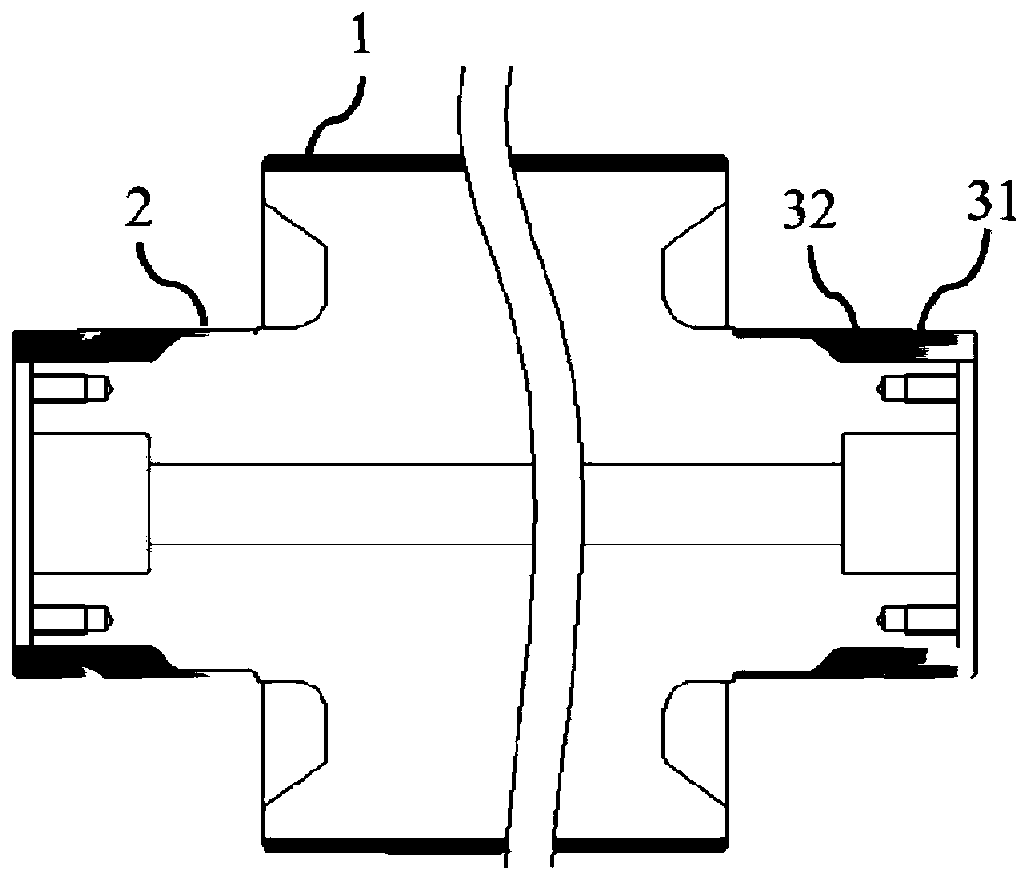

[0071] The method for repairing the spline of the driving roller shaft of the continuous casting roller in this embodiment has the same basic structure as that in Embodiment 1, the difference and improvement are: in step 1, the analysis module of proe5.0 is used to simulate the meshing force of the spline 3 ,Such as Figure 4 As shown, the spline 3 torque T1 is calculated according to the calculation formula of the circumferential force, radial force and normal force, where T1=Fr, the torque T1 is converted into the load force, and the spline 3 pitch circle and the width of the tooth surface Add the load at the intersection of the directions, and make the stress, strain and displacement finite element model of the spline 3 after being subjected to the rotational moment. According to the deformation per unit length generated under the maximum stress, the distance between the strain caused by the stress and the root of the tooth is obtained by analysis. , so as to determine the ...

Embodiment 3

[0077] A method for repairing the spline of the continuous casting roller driving roller shaft in this embodiment, the basic structure is the same as that of Embodiment 2, the difference and improvement lies in that it also includes a pre-welding preparation step, including:

[0078] Step A, determination of welding materials:

[0079] i) Use Φ3.2mm flux-cored wire CY430 with SJ604 flux (or flux HJ260) to weld the transition layer, ensuring that the single side is about 3mm;

[0080] ii) Use Φ3.2mmH2Cr13 flux-cored welding wire with SJ604 flux (or flux HJ260) to weld the wear-resistant layer on the cover surface, and the welding direction reciprocates;

[0081] Step B, process specification: the flux is baked at 250° C. for more than 2 hours, and used after cooling out of the oven.

[0082] In this embodiment, considering the fusion of the spline 3 body and the welding material, the material of the continuous casting roll is 21CrMoV5, and the welding material should contain e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com