A Multifunctional Machining Electrode System

An electrode system and multi-functional technology, applied in the direction of electrode characteristics, pressure electrodes, resistance electrode holders, etc., can solve the problems of low production efficiency, difficult to guarantee product quality, and inability to realize long welds, etc., to achieve high production efficiency and convenient operation , the appearance does not change the effect of discoloration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

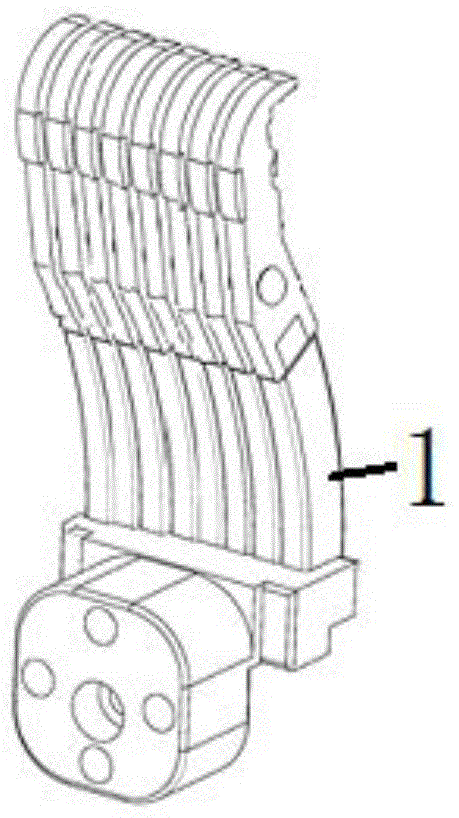

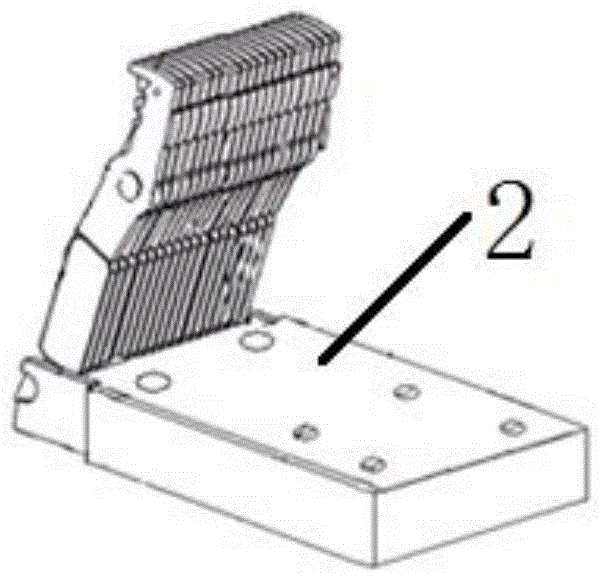

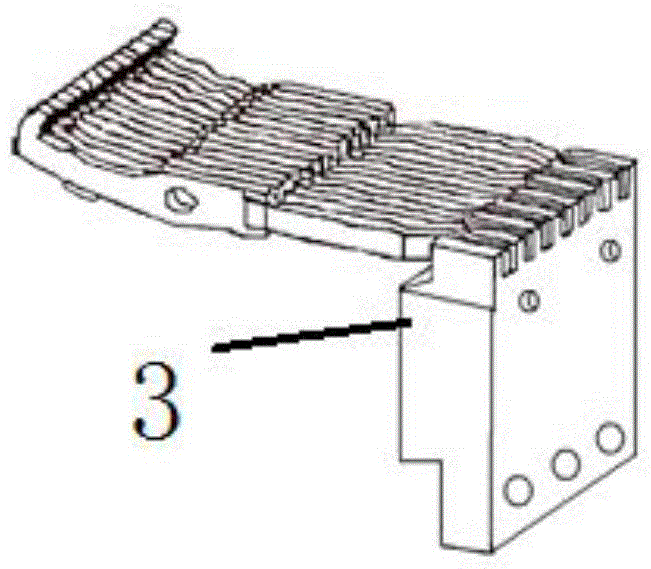

[0046] Such as Figure 1-Figure 6 As shown, it is the structure model of the movable contact of different specifications processed by the present invention, wherein, figure 1 Shown is the first type of single power moving contact 1, figure 2 Shown is the second type of single power moving contact 2, image 3 Shown is the third type of single power moving contact 3, Figure 4 Shown is the fourth type of single power moving contact 4, Figure 5 Shown is the board type dual power moving contact 5, Image 6 Shown is split type dual power moving contact 6.

[0047] The structure of the multifunctional processing electrode system of the present invention is that it includes three major parts: an upper electrode pressurizing mechanism 402, an intermediate electrode assembly 413 and a lower electrode assembly 404, and the intermediate electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com