Automatic soft metal line welding equipment

A technology of welding equipment and soft metal wires, which is applied in the direction of connections, circuit/collector parts, electrical components, etc., can solve problems such as inability to be welded and formed at one time, and achieve joints that are not loose, weld fusion, and high strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

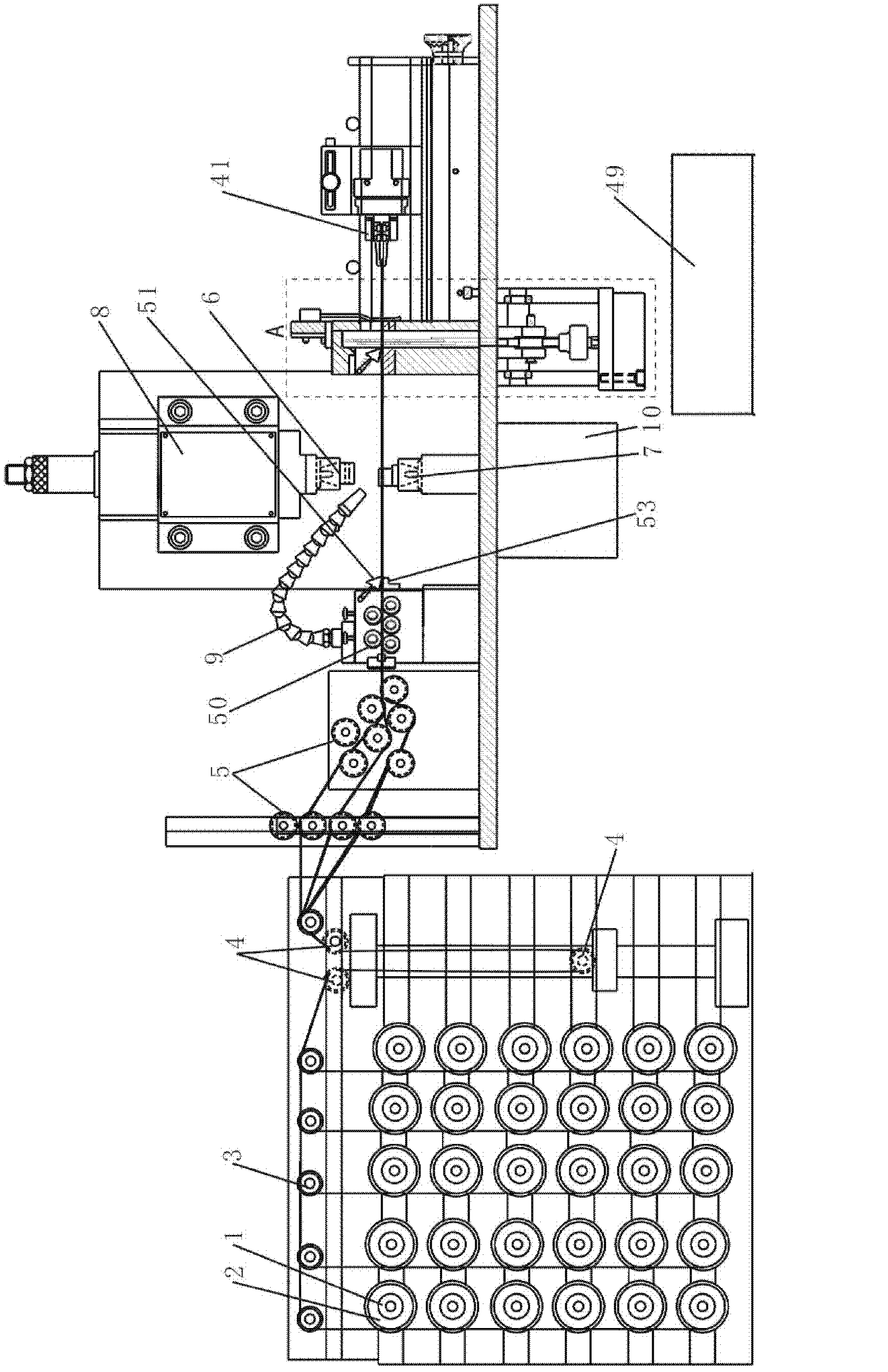

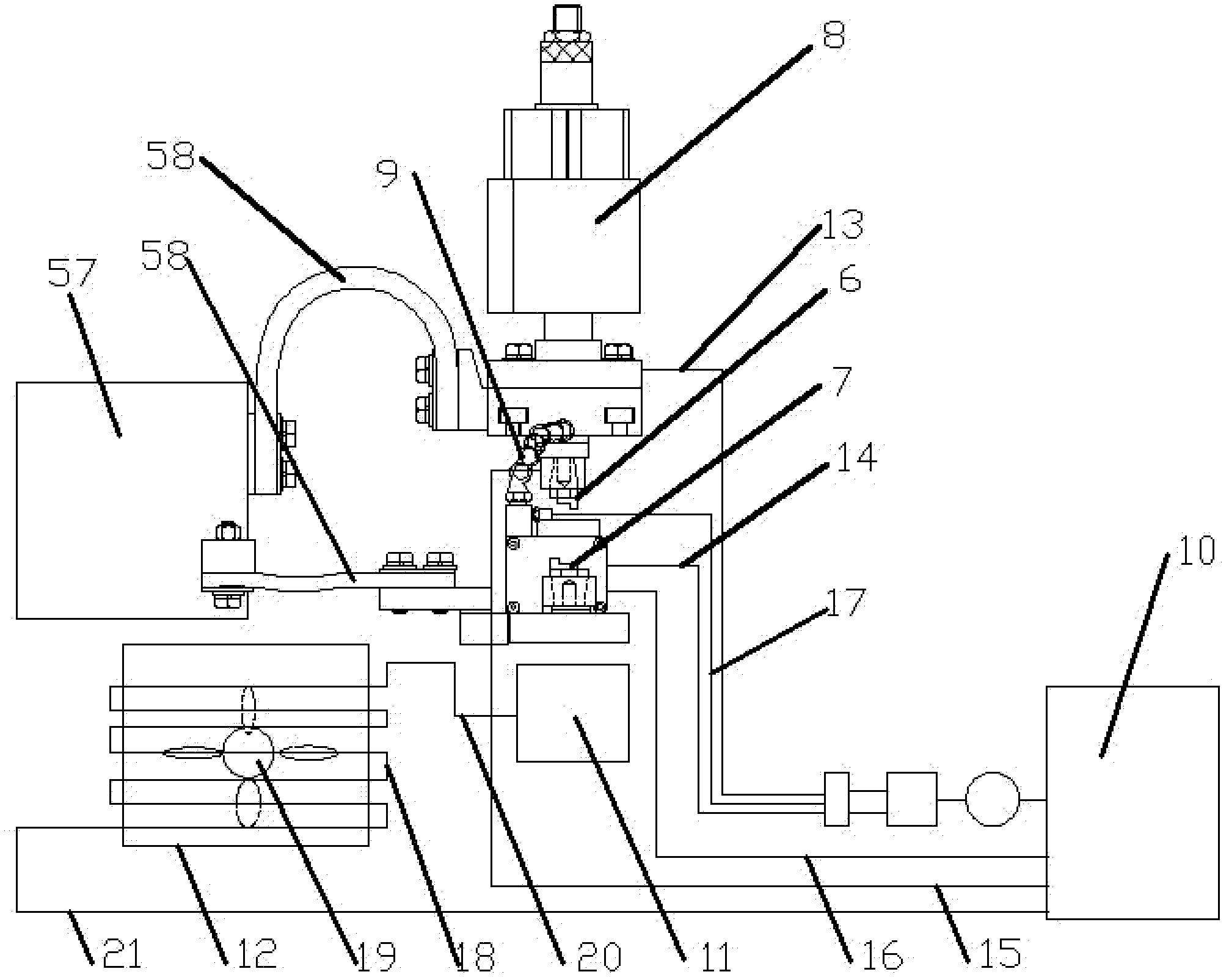

[0046] Such as figure 1 As shown, the present invention provides a fully automatic wire welding equipment for soft metal wires, which includes a soft wire closing part, a soft wire straightening part, a crimping roller set, a welding part, a cutting part and a fixed-length drawing part arranged in sequence; Including cooling part, feeding part and clamping part.

[0047] The soft wire closing part includes a plurality of pay-off reels 1, and the plurality of pay-off reels 1 are arranged in M rows×N columns. Each pay-off reel 1 is provided with a coil 2, and each column of pay-off reels 1 is provided with a first One scroll wheel3.

[0048] The cord straightening part is made up of three second rollers 4 in a "V" shape.

[0049] The crimping roller group is made up of a plurality of the 3rd roller 5.

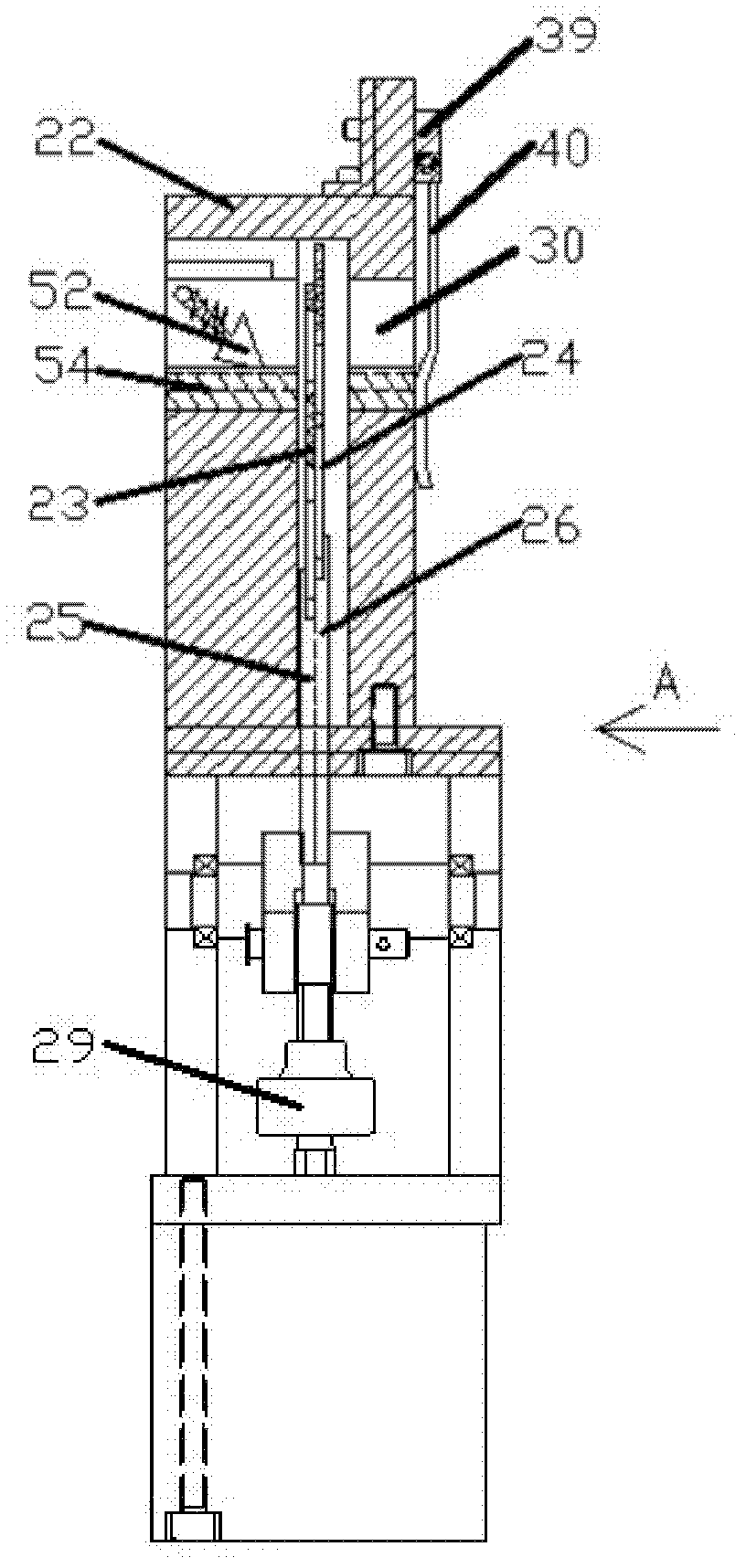

[0050] The welding part includes an upper welding joint 6 and a lower welding joint 7, such as Figure 13 As shown, the upper welding head 6 is made up of the first electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com