Heavy metal adsorbent, preparation method and application thereof

A technology for adsorbents and heavy metals, applied in the direction of alkali metal compounds, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of waste of resources, easy reunion of waste MTP catalysts, etc., to improve reactivity, improve separation and recovery performance , to achieve the effect of efficient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A second aspect of the present invention provides a method for preparing a heavy metal adsorbent, the method comprising:

[0036] (1) Mix waste MTP catalyst, ethanol solution and iron salt to obtain a mixed solution;

[0037] (2) Reducing the mixed solution to obtain a heavy metal adsorbent.

[0038] In the present invention, the above-mentioned limitations are used for the spent MTP catalyst, and details are not repeated here.

[0039] According to the present invention, preferably, the method further includes: before mixing, roasting the spent MTP catalyst, so as to improve the strength and stability of the spent MTP catalyst.

[0040] Preferably, the calcination conditions include: the temperature is 350-700°C, preferably 450-600°C, and the time is 1-15h, preferably 3-10h. Optimum calcination conditions are more conducive to improving the strength and thermal stability of the spent MTP catalyst.

[0041] In the present invention, unless otherwise specified, the et...

Embodiment approach

[0058] According to a preferred embodiment of the present invention, the heavy metal adsorbent is first washed with absolute ethanol for 3-5 times, then rinsed with oxygen-free deionized water for 3-5 times, filtered with suction, and dried in a vacuum drying oven, and then Keep airtight.

[0059] The third aspect of the present invention provides a heavy metal adsorbent prepared by the above method.

[0060] The fourth aspect of the present invention provides an application of the heavy metal adsorbent mentioned above in the adsorption of heavy metal ions in wastewater.

[0061] In the present invention, the heavy metal ion has a wide selection range, preferably, the heavy metal ion is selected from Pb 2+ 、Cu 2+ 、Cd 2+ and Cr 6+ at least one of the

[0062] According to the present invention, preferably, the concentration of heavy metal ions in the waste water is independently 100-1500 mg / L, more preferably 100-500 mg / L. For example, the wastewater described in the test...

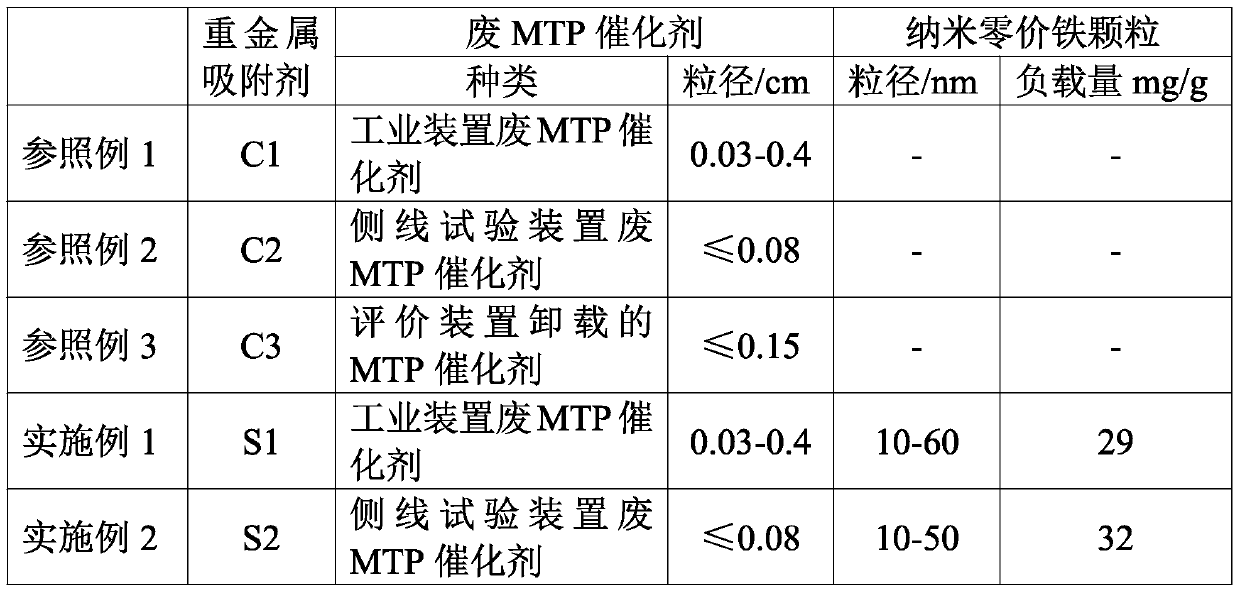

Embodiment 1

[0073] (1) Take the 5-40 mesh sieve sample after crushing the waste MTP catalyst (reference example C1) with ZSM-5 molecular sieve as the main body collected by the 500,000 tons of MTP industrial device of Ningmei Coal Company of Guoneng Group, and put it in the muffle furnace Calcined at 550°C for 4h, in a nitrogen atmosphere, 10g of the calcined spent catalyst was mixed with 100mL of 70% ethanol solution, 1.5g of FeSO 4 ·7H 2 O was stirred at 25° C. for 30 min in water to obtain a mixed solution;

[0074] (2) Continuing to pass nitrogen gas, 150mL of 0.1mol / L NaBH 4 The solution is added dropwise into the mixed solution at a rate of 3 drops / second for reaction, wherein the temperature is 50°C and the time is 200 minutes;

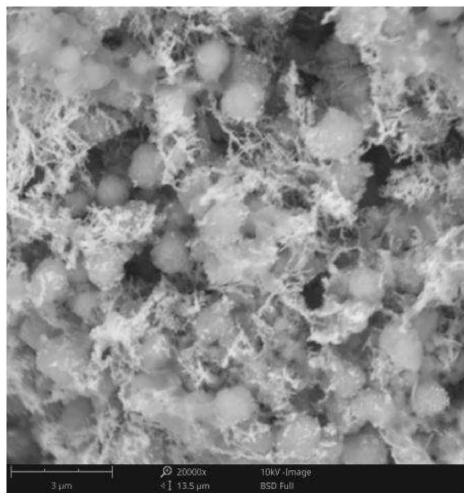

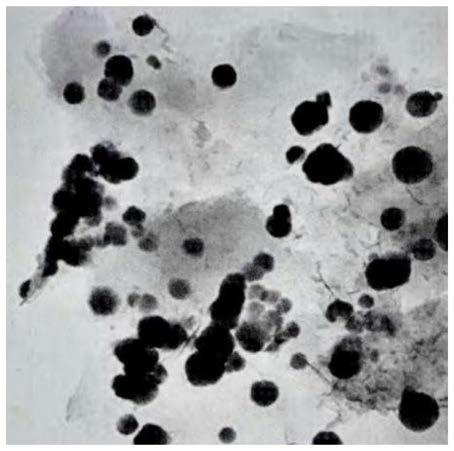

[0075] (3) After the solid-liquid separation of the product in step (2), wash 3 times with absolute ethanol, then rinse 3 times with anaerobic deionized water, filter with suction, dry in a vacuum drying oven at 80°C for 24 hours, seal and store, to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| Loading capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com