Method for preparing artificial soil with shale gas water-based drilling cuttings and sludge fermentation products

A technology of fermentation products and artificial soil, applied in the directions of botanical equipment and methods, culture medium, planting substrate, etc., can solve the problem that mellow soil cannot be widely applied, and the utilization and consumption of water-based drilling cuttings building materials is limited and cannot be used. It can meet the problems of shale gas treatment progress after drilling, and achieve the effect of good water retention and permeability, expansion of resource utilization methods, and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

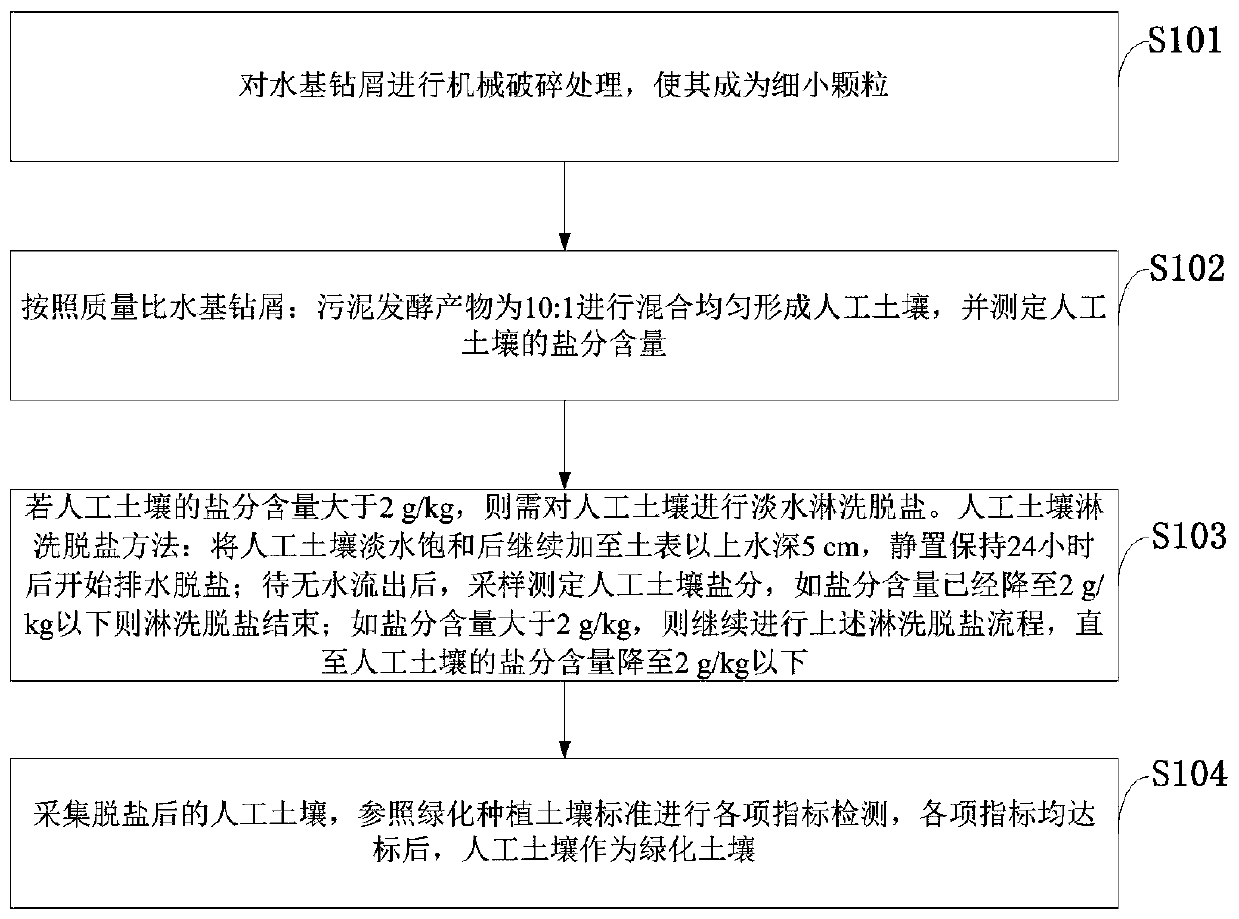

Method used

Image

Examples

Embodiment 1

[0043] The main physical and chemical properties of the artificial soil of the embodiment of the present invention: the total salt content is 0.92g / kg, the pH is 8.2, the contents of alkali-hydrolyzable nitrogen, available phosphorus, and available potassium are respectively 176mg / kg, 79.6mg / kg, and 5252mg / kg; 1.1g / cm 3 , which meets the technical requirements in CJ / T340-2016 "Green Planting Soil", and can be used as green planting soil.

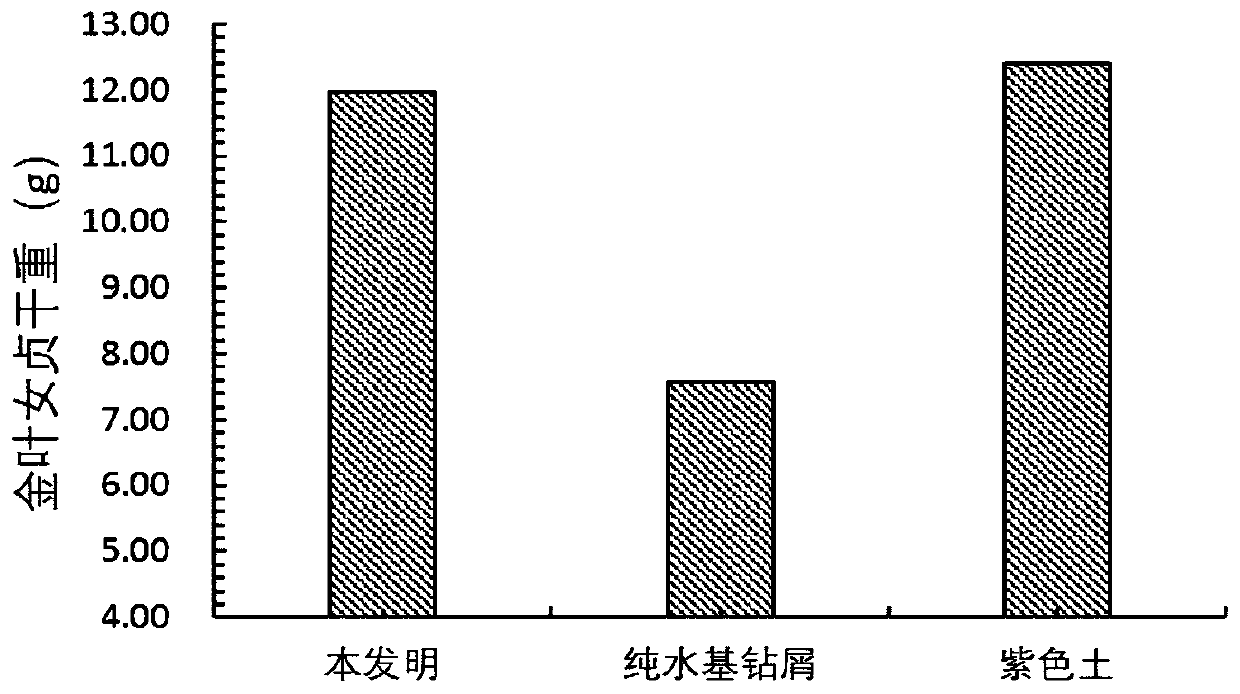

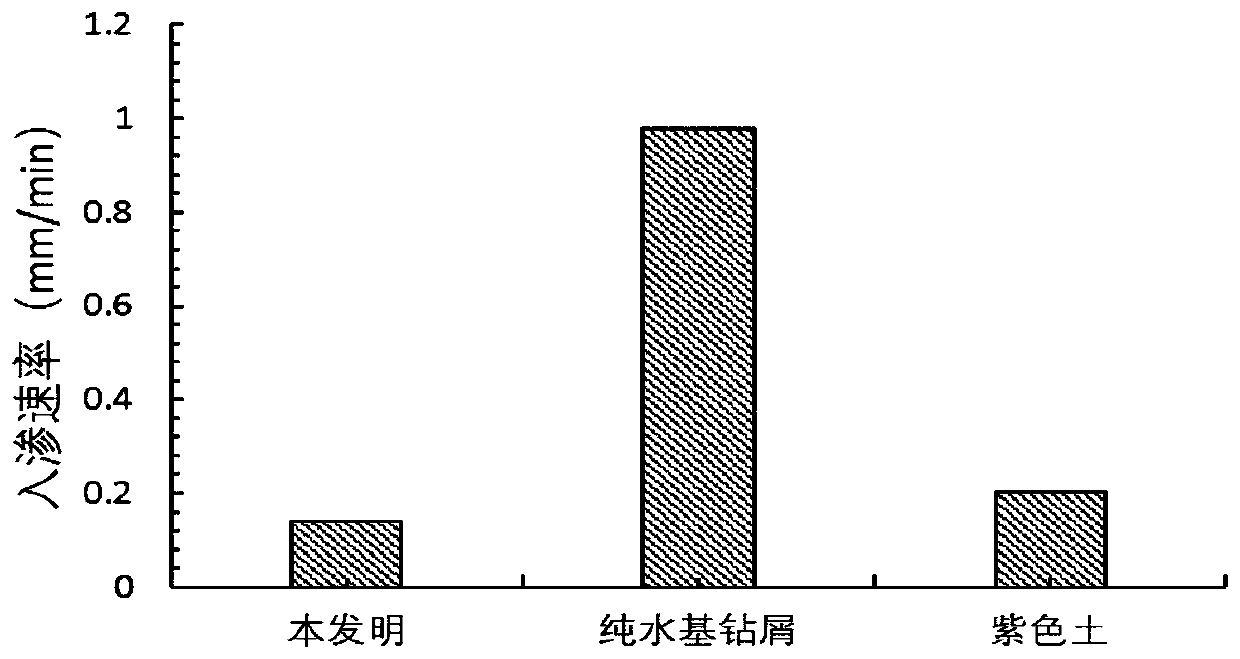

[0044] The implementation site is located in the green belt of a leisure square in Fuling District, Chongqing City, with a total of 30m 2 ; 10m each of artificial soil, pure water-based drilling cuttings and purple soil were arranged 2 (divided into 3 sections), wherein pure water-based drilling cuttings and purple soil are used as the application effect control area of the present invention. Cover the green area with 40cm thick artificial soil, pure water-based cuttings, and purple soil, and control the soil bulk density of the correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com