Saline-alkali soil improver as well as preparation method and application thereof

A soil conditioner and saline-alkali technology, which is applied in the field of saline-alkaline soil conditioner and its preparation, can solve environmental problems, human hazards and other problems, and achieve the effects of low material cost, reduced loss, and improved plant tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

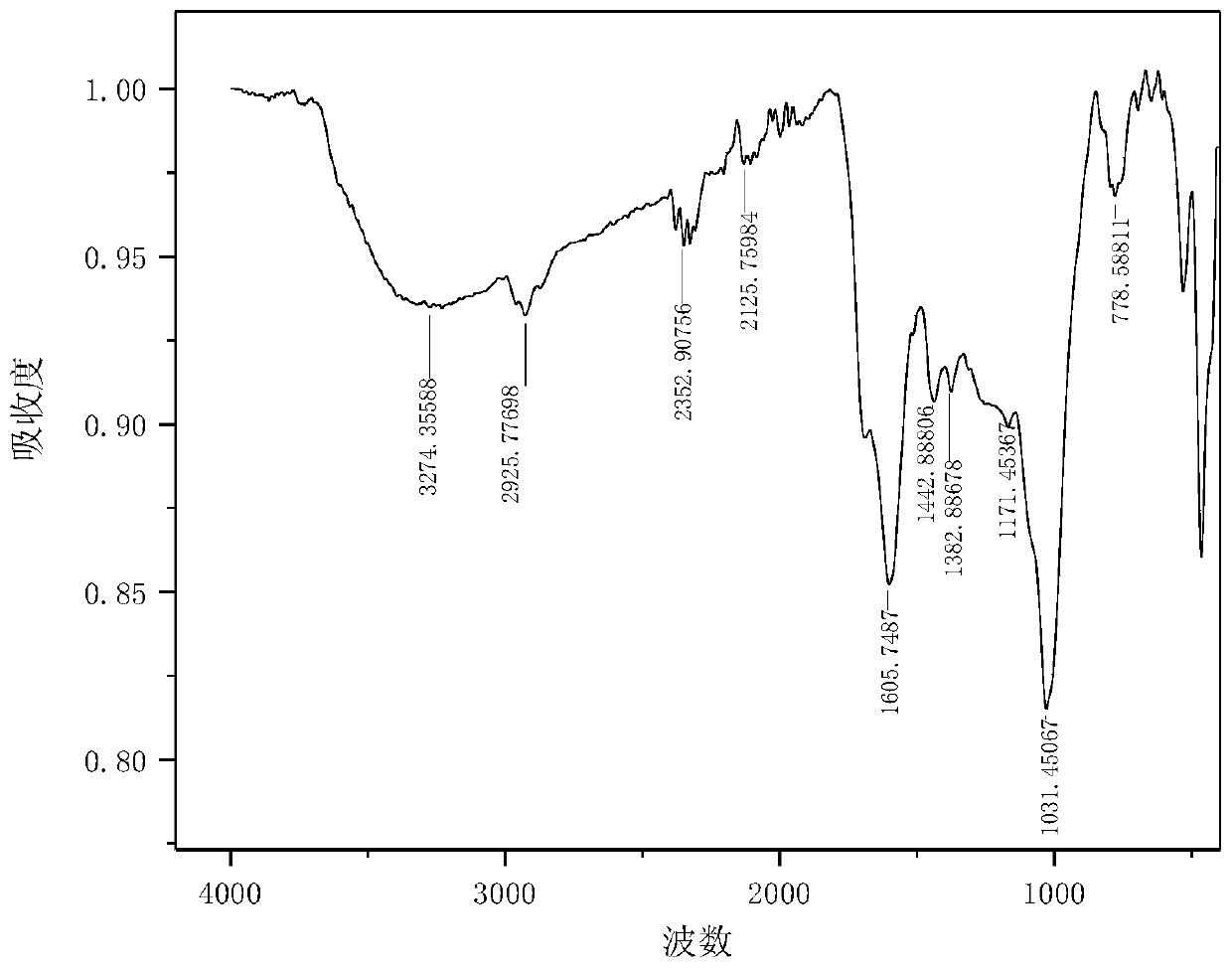

Image

Examples

Embodiment 1

[0034] This embodiment provides a kind of saline-alkaline soil improving agent, and the preparation method comprises the following steps:

[0035] 1) Mix corn stalks and sunflower stalks with a mass ratio of 1:1 to prepare straw biochar;

[0036] 2) Collect mung bean seeds that cannot germinate, wash, crush and crush, pass through a 10-mesh sieve, take the under-sieve and soak for 2 days to obtain auxiliary materials;

[0037]3) Mix 300 g of auxiliary materials in step 2 with 200 g of straw biochar, 4 g of yeast agent, and 2000 g of water in step 1), seal with gauze, and ferment for 80 days to obtain a fermentation mixture; wherein, the fermentation conditions are: keep auxiliary materials and straw biochar and The temperature of the water mixture was 30° C. for 7 days, inoculated yeast inoculum, and adjusted the water content once every 3 days to maintain the water content in the fermentation vessel. During fermentation, shake 6 times.

[0038] 4) separating the solid from ...

Embodiment 2

[0042] This embodiment provides a kind of saline-alkaline soil improving agent, and the preparation method comprises the following steps:

[0043] 1) Mix corn stalks and sunflower stalks with a mass ratio of 1:1 to prepare straw biochar;

[0044] 2) Collect mung bean and soybean seeds that cannot germinate, wash, crush and crush, pass through a 10-mesh sieve, take the under-sieve and soak for 2 days to obtain auxiliary materials; wherein, the weight ratio of soybean seeds and mung bean seeds is 1:1;

[0045] 3) Mix 300 g of auxiliary materials in step 2 with 200 g of straw biochar, 4 g of yeast agent, and 2000 g of water in step 1), seal with gauze, and ferment for 80 days to obtain a fermentation mixture; wherein, the fermentation conditions are: keep auxiliary materials and straw biochar and The temperature of the water mixture was 30° C. for 7 days, inoculated yeast inoculum, and adjusted the water content once every 3 days to maintain the water content in the fermentation ...

Embodiment 3

[0049] This embodiment provides a kind of saline-alkaline soil improving agent, and the preparation method comprises the following steps:

[0050] 1) Mix corn stalks and sunflower stalks with a mass ratio of 1:1 to prepare straw biochar;

[0051] 2) Collect mung bean and soybean seeds that cannot germinate, wash, crush and crush, pass through a 10-mesh sieve, take the under-sieve and soak for 2 days to obtain auxiliary materials; wherein, the weight ratio of soybean seeds and mung bean seeds is 1:1;

[0052] 3) Combine step 2) 150g of auxiliary materials with step 1) 200g of straw biochar, 5g of yeast inoculum, and 2000g of water, seal with gauze, and ferment for 90 days to obtain a fermentation mixture; wherein, the fermentation conditions are: keep the auxiliary materials and straw biochar and The temperature of the water mixture was 30° C. for 7 days, inoculated yeast inoculum, and adjusted the water content once every 3 days to maintain the water content in the fermentatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com