Solid-liquid separator suitable for various livestock and poultry feces and operation method thereof

A technology of solid-liquid separator and livestock and poultry manure, which is applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve the problems of unsuitable treatment of high-viscosity manure, limited types of manure, and high cost of screen replacement. Achieve the effect of improving solid removal rate, reducing labor intensity and convenient transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

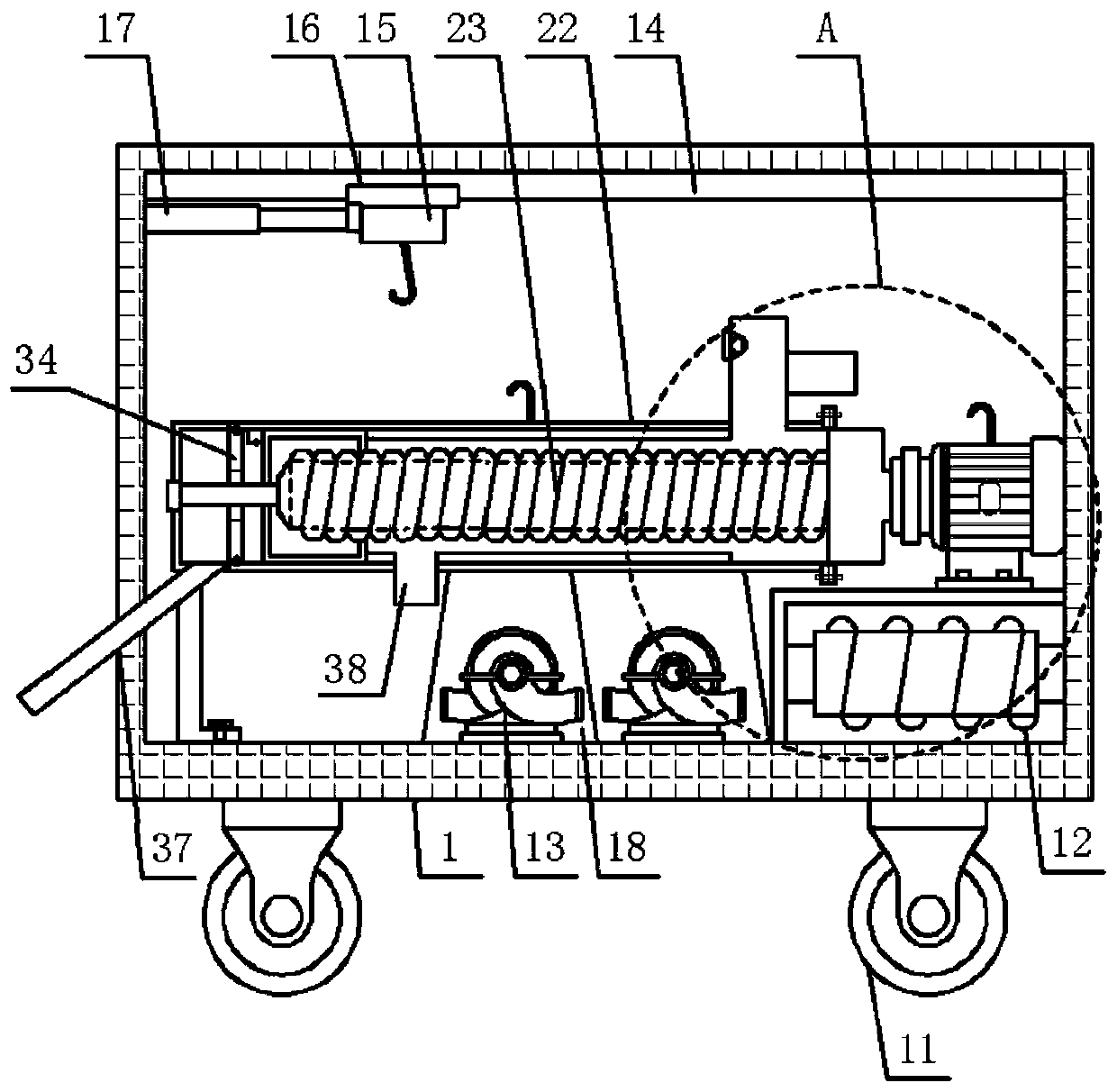

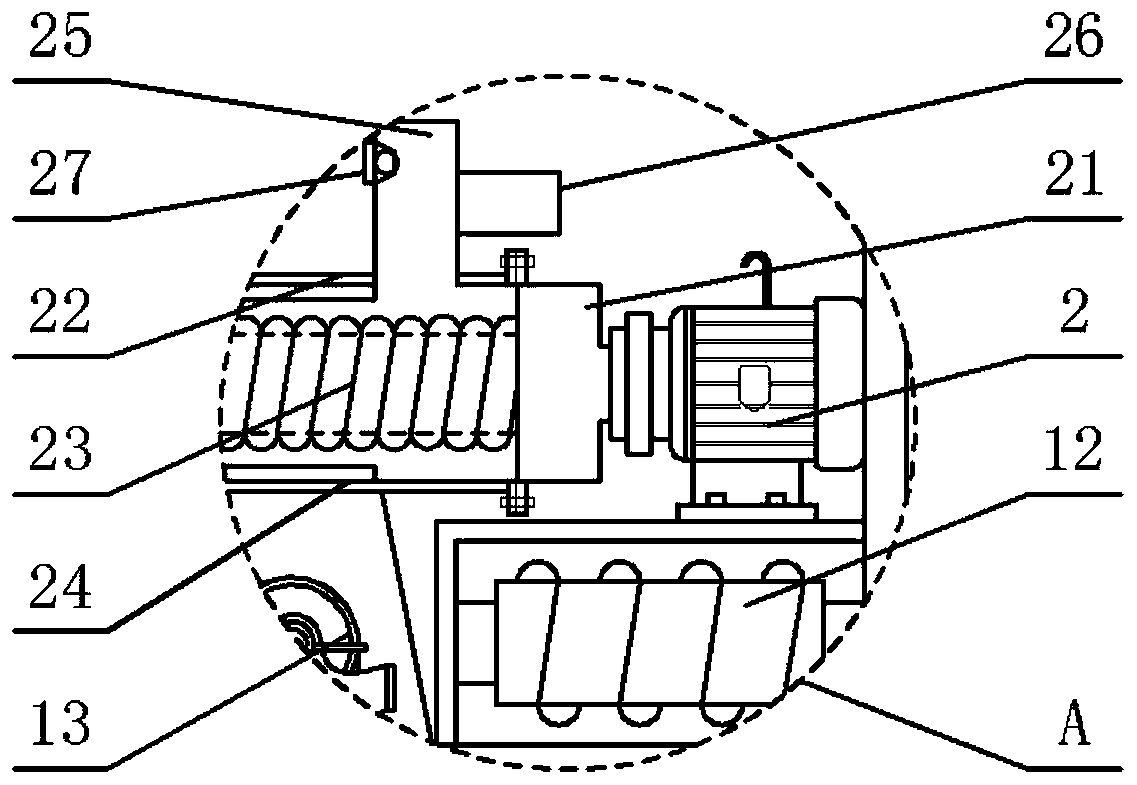

[0039] Embodiment 1: In order to realize the solid-liquid separation treatment of current livestock and poultry manure, improve efficiency, and ensure separation quality, this embodiment provides a solid-liquid separator. Specifically, see Figure 1-9, a solid-liquid separator adapted to various livestock and poultry manure, comprising a frame 1, the frame 1 is a horizontally arranged rectangular frame, the bottom and top of the frame 1 are respectively provided with a rectangular bottom plate and a top plate, The four corners of the bottom plate and the top plate are fixedly connected by longitudinal rods; the middle part of the bottom plate of the frame 1 is longitudinally provided with a trapezoidal support base 18, and the top surface of the support base 18 is horizontally recessed with an arc-shaped groove. The inner shell 22 is placed horizontally, see Figure 7 , both sides of the outer wall of the housing 22 are laterally extended with fixing plates 221, and each fixin...

Embodiment 2

[0046] Embodiment 2: In this embodiment, in order to better realize the solid-liquid separation operation of feces, see Figure 4 , further, the helical blades 28 distributed on the helical shaft 23 adopt a three-stage distribution from front to back, wherein,

[0047] The first section is located below the feed pipe 26. Two first continuous helical blades 283 that are staggered are distributed in the first section. The first continuous helical blades 283 are equal-pitch spirals. The screw pitch is 1.5-2.5 times, providing enough forward thrust to realize the rapid forward transport of dung water, at this time, part of the free water in the dung water is directly discharged through the screen;

[0048] see Figure 4 , Figure 5 , there are 3-6 helical structures with broken teeth distributed in the gap in the second section. The helical structure with broken teeth is a double helix structure formed by two broken tooth blades 282 interlaced. It is staggered in the radial dir...

Embodiment 3

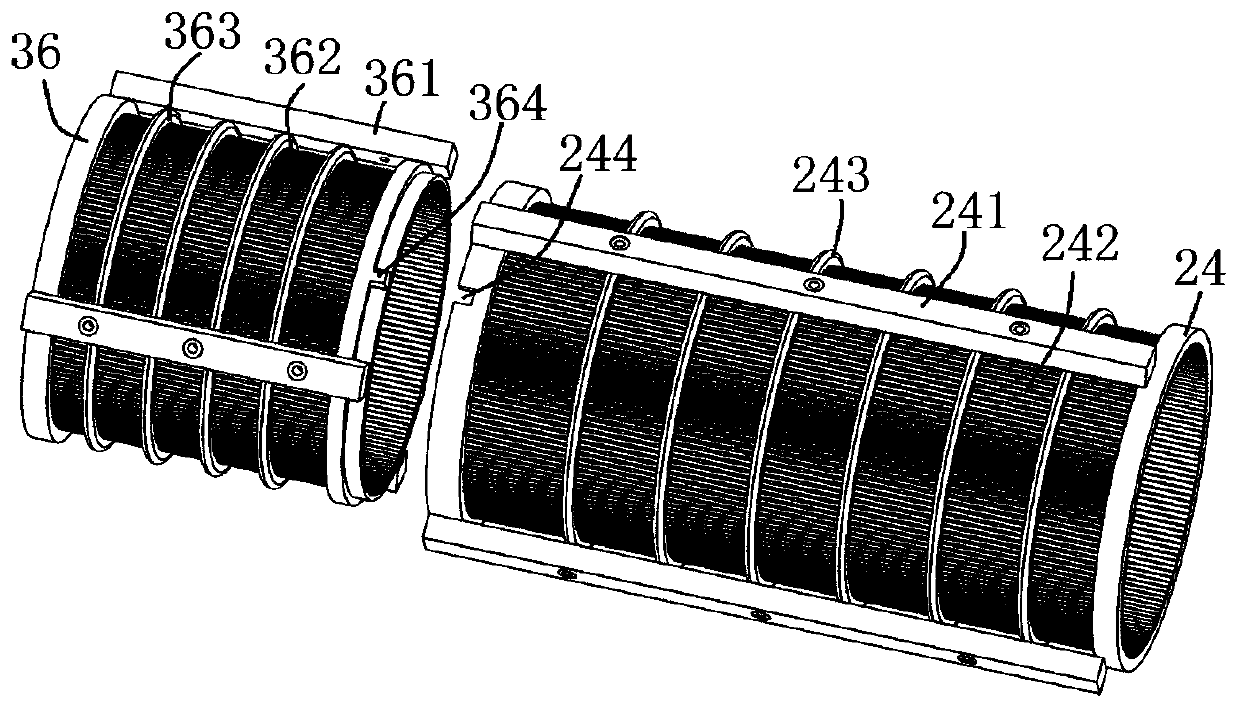

[0050] Embodiment 3: In this embodiment, see image 3 , in order to facilitate the maintenance and replacement of the screen, structurally, the front and rear ends of the first screen 24 are first circular rings arranged in parallel, and a plurality of blocks are axially distributed and fixed on the outer walls of the first circular rings at both ends. The first mounting plate 241, the first screw holes are distributed on the first mounting plate 241; a plurality of annular first reinforcing rings 243 are axially equidistantly distributed in the first ring gap parallel to both sides, each first The first filter plate 242 is annularly distributed on both side walls of the reinforcement ring 243; the snap-fit opening 244 is distributed on the first circular ring at the rear end;

[0051] The front and rear ends of the second screen 36 are second rings arranged in parallel, and the outer walls of the second rings at both ends are axially distributed and fixedly connected with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com