Acidizing temporary plugging agent as well as preparation method and application thereof

A technology of temporary plugging agent and cross-linking agent, which is applied in the field of acidified temporary plugging agent and its preparation, can solve the problems of incomplete degradation of acidified temporary plugging agent, complicated preparation technology, and low mechanical properties, etc., to achieve increased degradable performance, Broad application prospects and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

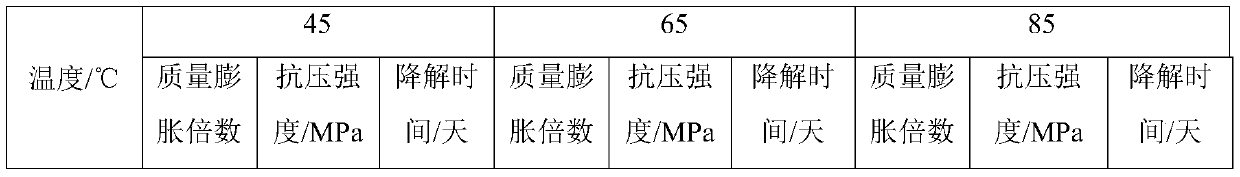

Examples

preparation example Construction

[0031] The preparation method of used polybutylacrylate emulsion is:

[0032] (1) Add 300g of deionized water, 100g of butyl acrylate, 0.25g of dodecyl mercaptan, 1.2g of sodium lauryl sulfate, polyethylene Diol octyl phenyl ether 3.6g.

[0033] (2) Start the mechanical stirring, keep the rotation speed at 400rpm, emulsify at room temperature for 15 minutes, and pass nitrogen protection, and heat the reaction kettle to 70°C with a circulating water bath.

[0034] (3) Weigh 0.48 g of potassium persulfate, dissolve it in 8 mL of pure water, and inject it with a syringe.

[0035] (4) Keep the rotational speed at 400 rpm, react at 70° C. for 1 hour, then end the reaction, and cool to room temperature to obtain a polybutylacrylate emulsion.

Embodiment 1

[0037] A kind of preparation method of acidification temporary plugging agent, comprises steps as follows:

[0038] Add 2g sodium carboxymethylcellulose and 60g distilled water to the reaction kettle, stir and dissolve; then add 10g polybutylacrylate emulsion, 26.6g acrylamide, 1.4g maleic anhydride, 0.18g ethylene glycol diacrylate, 0.12 g ammonium persulfate, mixed evenly, and reacted at 45°C for 5 hours to obtain an elastic gel, which was granulated, dried, and pulverized to obtain an acidified temporary plugging agent.

Embodiment 2

[0040] A kind of preparation method of acidification temporary plugging agent, comprises steps as follows:

[0041] Add 2.5g sodium hydroxypropyl cellulose and 61g distilled water to the reaction kettle, stir and dissolve; then add 11g polybutylacrylate emulsion, 22.9g acrylamide, 1.0g acrylic acid, 0.14g ethylene glycol diacrylate and 0.11g Ammonium persulfate, mixed evenly, reacted at 45°C for 5 hours to obtain an elastic gel; the obtained gel was granulated, dried, and pulverized to obtain an acidified temporary plugging agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Salinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com