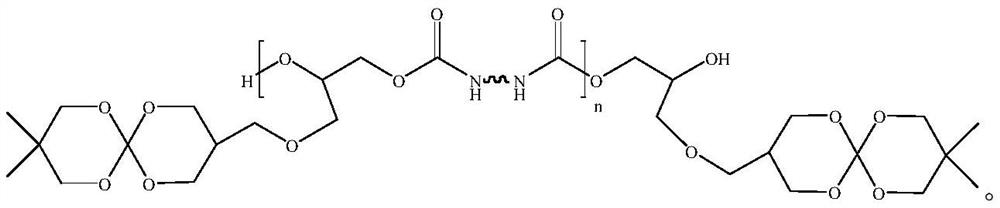

A kind of low-shrinkage cable material resin and preparation method thereof

A cable material resin and low-shrinkage technology, applied in the field of low-shrinkage cable material resin and its preparation, can solve the problems of low volume shrinkage, poor oil resistance, poor wear resistance, etc., achieve high reactivity, solve poor shrinkage resistance, and wide Market Space Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

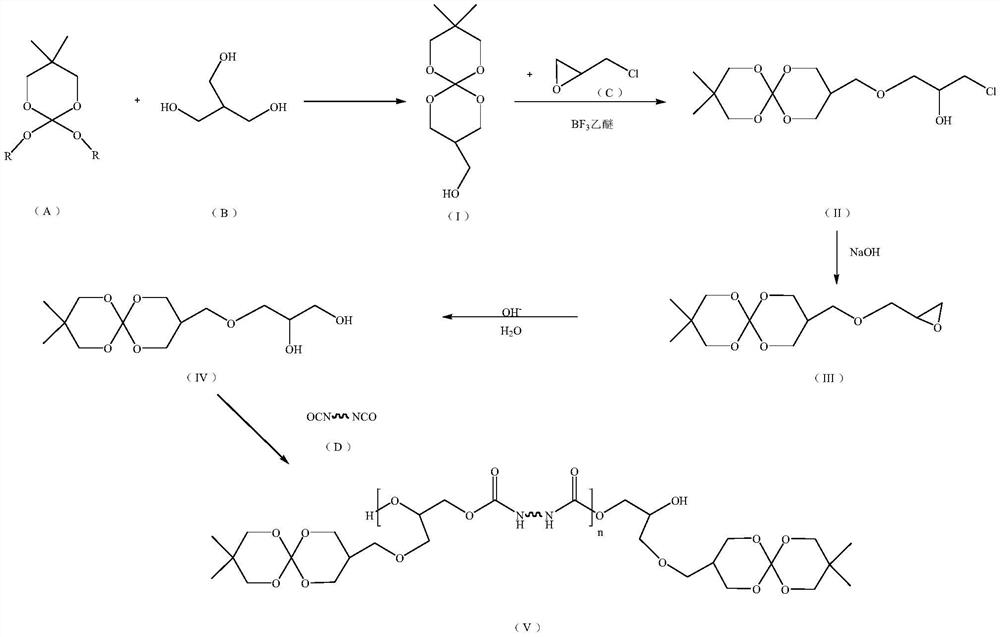

Method used

Image

Examples

Embodiment 1

[0052] Step (1) 1mol 1,3-dioxane-2,2-diethoxy-5,5-dimethyl-(9CI)(A), 1mol 2-hydroxymethyl-1,3 propanediol (B), 3wt% potassium carbonate is mixed and dissolved in 20mol toluene, stirred for 3h at 70°C, left to stand, filtered, and distilled under reduced pressure at 40°C to obtain the intermediate product I (IR: 1204cm -1 、1105cm -1 : spiro-C-O-C-existence; 3315cm -1 : -OH exists; 2963cm -1 :-CH 3 exist);

[0053] The dosage of potassium carbonate is 3wt% of the mass of 1,3-dioxane-2,2-diethoxy-5,5-dimethyl-(9CI).

[0054] Step (2) 1mol I is added to the solution containing 3wt% BF 3 In 1.2mol epichlorohydrin (C) in diethyl ether, heat to 80°C, react for 2h; stand still, and distill under reduced pressure at 40°C to obtain intermediate product II (IR: 1204cm -1 、1105cm -1: spiro-C-O-C-existence; 3393cm -1 : -OH exists; 747cm -1 :-C-Cl exists);

[0055] The BF 3 Ether consumption is 3wt% of 1 quality.

[0056] Step (3) Add 1.2 mol of sodium hydroxide to 1 mol of II, ...

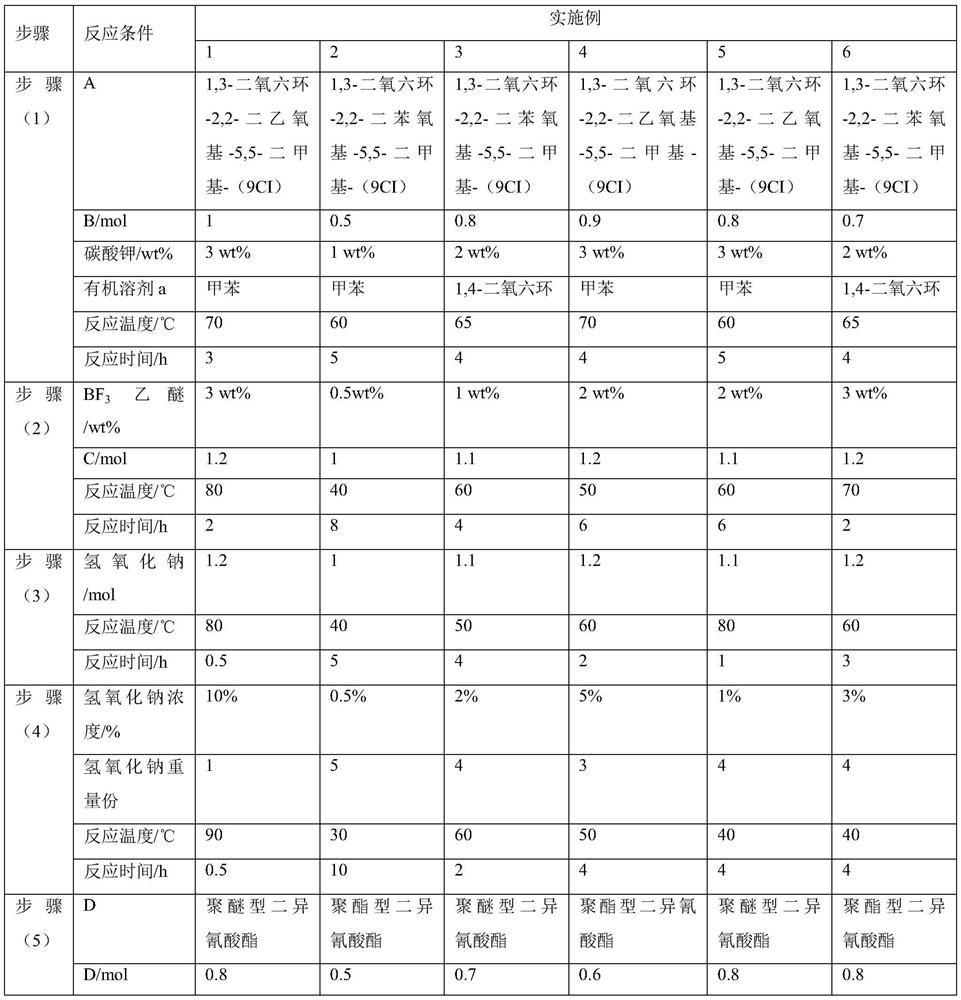

specific Embodiment 2-6

[0060] Specific embodiment 2-6, other are with specific embodiment 1, difference is following table:

[0061]

[0062]

[0063] The low-shrinkage cable material resin obtained in Example 1 is used as the base material of the application example, and processed to form a low-shrinkage cable sheath.

[0064] The flame retardant described in the present invention is magnesium hydroxide and aluminum hydroxide in a mass ratio of 3:1; the antioxidant is tetrakis[β-(3',5'-di-tert-butyl-4'-hydroxyphenyl) Propionic acid] pentaerythritol ester; filler: nano-titanium dioxide; curing accelerator: N,N-dihydroxypropyl-p-toluidine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com