Nano zirconia material, its preparation method and application

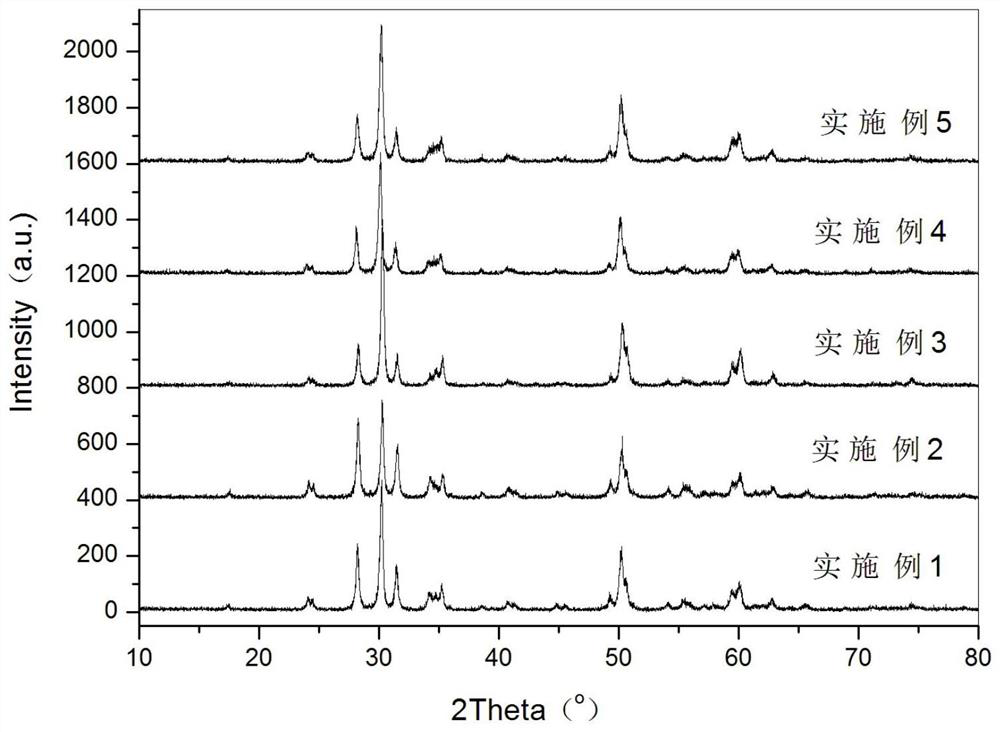

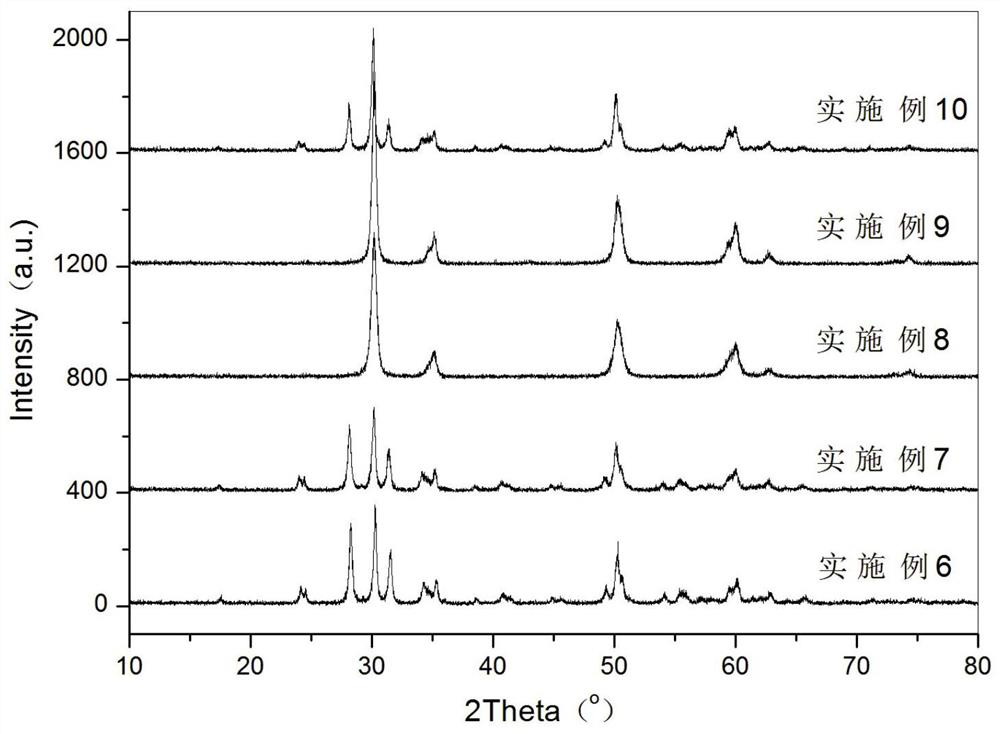

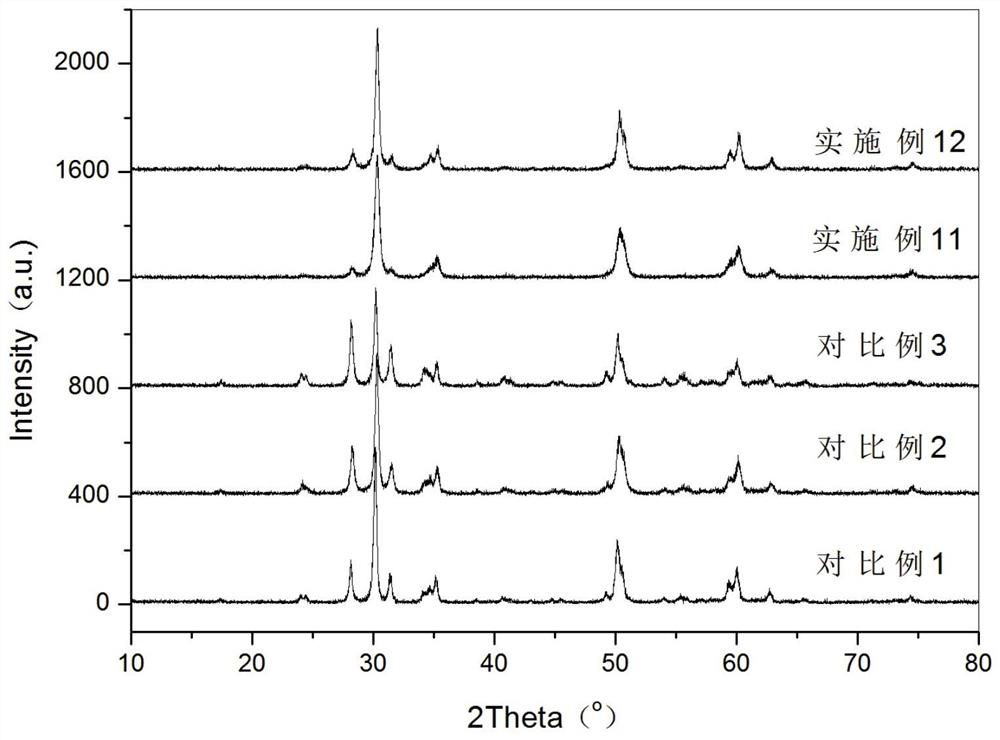

A technology of nano-zirconia and zirconia, which is applied in the direction of zirconia, chemical industry, sustainable manufacturing/processing, etc., can solve the problems of poor dielectric properties and complicated procedures of nano-zirconia, achieve small particle size distribution, improve Diffraction intensity, effect of increasing crystallinity

Active Publication Date: 2022-05-31

SHANDONG SINOCERA FUNCTIONAL MATERIAL CO LTD

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] The main purpose of the present invention is to provide a nano-zirconia material, its preparation method and application, so as to solve the problem of poor dielectric properties or complex process of nano-zirconia in the prior art

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

[0029] More preferably, the first reaction temperature is 75-90 °C, and the second reaction temperature is 135-180 °C.

[0037] More preferably, the solvent used in the configuration mixed solution and the urea solution is water.

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides a nano zirconia material, its preparation method and application. The dielectric constant of the nano-zirconia material is 18.01-19.97 at 20GHz, and the dielectric loss tangent is 0.0008-0.0027; the dielectric constant at 28GHz is 18.46-21.27, and the dielectric loss tangent is 0.0012-0.0035; The dielectric constant is 18.73-23.88, the dielectric loss tangent is 0.0041-0.0078; the dielectric constant at 65GHz is 19.75-25.35, the dielectric loss tangent is 0.0031-0.0073; the dielectric constant at 70GHz is 20.68-26.26, The dielectric loss tangent is 0.0043-0.0080. The nano-zirconia material has excellent dielectric properties and is suitable for applications such as 5G communication consumer electronics dielectric substrates, mobile phone backplanes, and fingerprint identification. It is a ceramic material that can be applied in the millimeter wave frequency band.

Description

Nano-zirconia material, its preparation method and application technical field The present invention relates to the field of inorganic nanomaterial preparation, specifically, relate to a kind of nanometer zirconia material, its preparation methods and applications. Background technique [0002] 5G has the characteristics of high speed, low latency (only 1ms latency), low energy consumption, and full network coverage. With communication equipment The operating frequency continues to increase, the signal delay will become more obvious, and the loss and heat generation of the system will also increase. The dielectric properties of the bond material are required to be higher. Nano-zirconia is a kind of ceramic material integrating superior electrical properties and mechanical properties, which is used in electronic ceramics. Porcelain, functional ceramics and structural ceramics have a wide range of applications. Zirconia has three crystal phases with different structu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C04B35/626C04B35/48C01G25/02

CPCC04B35/62685C04B35/62675C04B35/48C01G25/02C01P2002/72C01P2004/64C01P2002/30C01P2004/62C01P2006/40C04B2235/3225C04B2235/5445C04B2235/5454C04B2235/96Y02P20/10

Inventor 宋锡滨赵莎王军焦英训

Owner SHANDONG SINOCERA FUNCTIONAL MATERIAL CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com