Current sensor error rapid on-line self-correcting motor driving system and control method

A motor drive system, current sensor technology, applied in the direction of motor generator control, electronic commutation motor control, AC motor control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0096] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

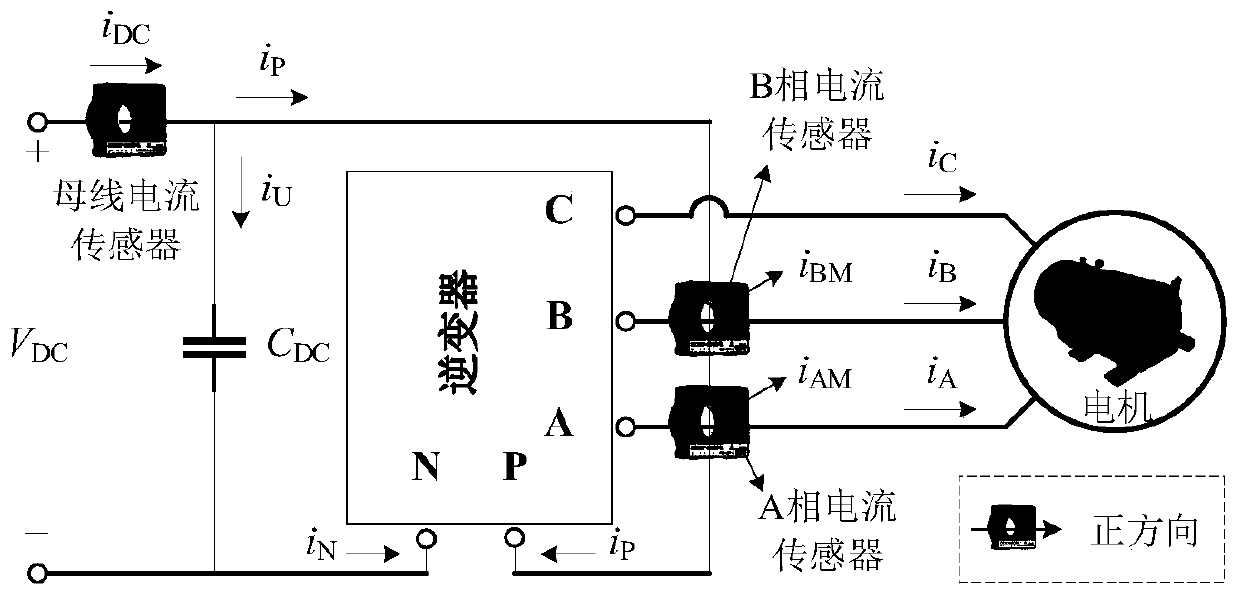

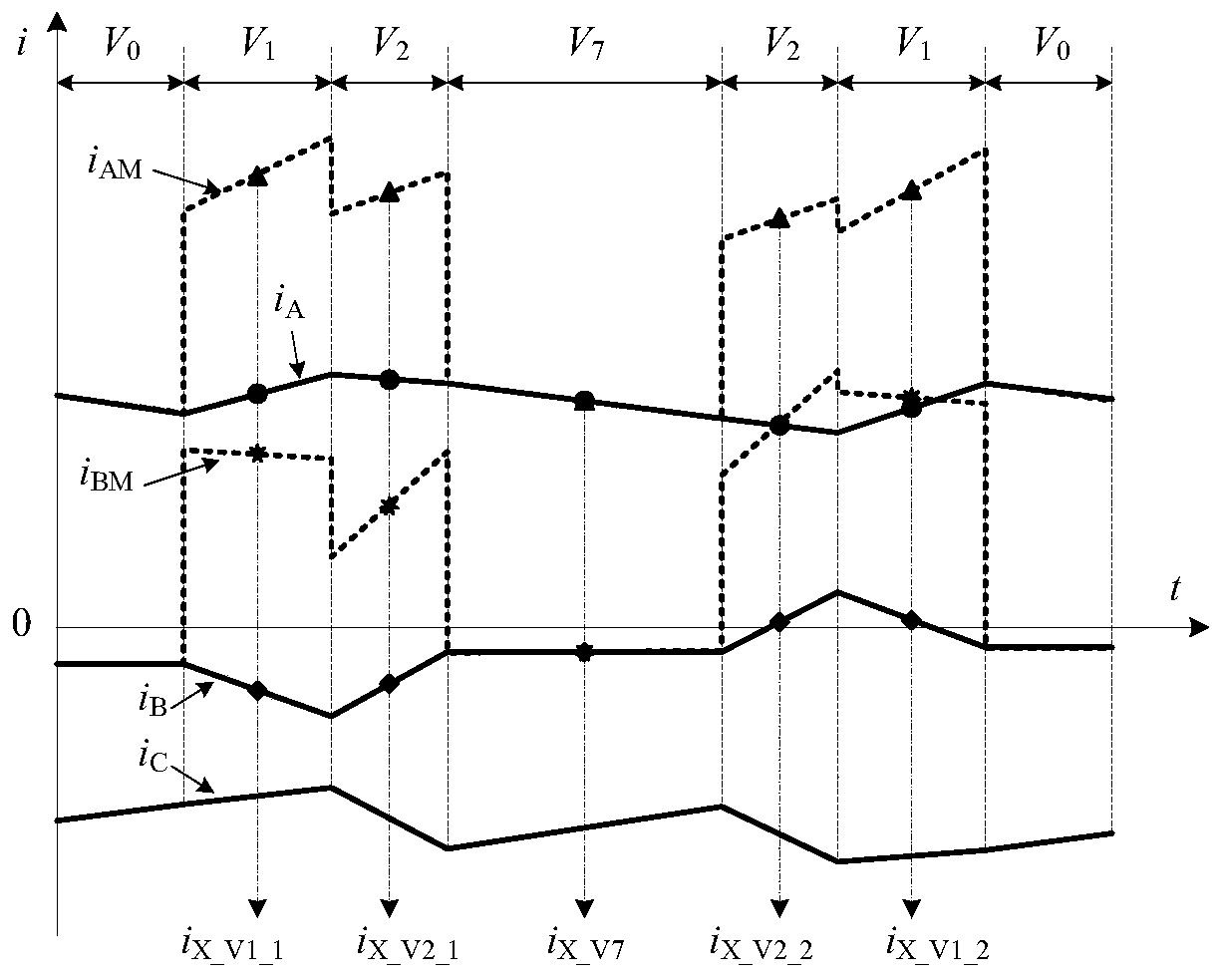

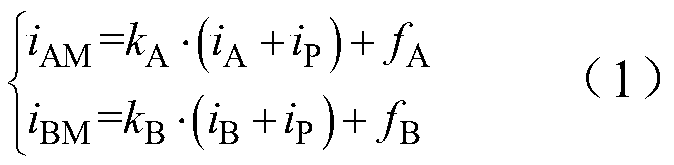

[0097] A current sensor error fast online self-correcting motor drive system. In the three-phase motor drive control system, the inverter is powered by the DC bus voltage, and the three-phase windings of the motor are respectively connected to the output three-phase interface of the inverter. The motor A , B two-phase winding input cables are forwardly through the A, B two-phase current sensor signal acquisition ports, and the cables input to the positive end of the inverter are also forwardly through the A, B two-phase current sensor signal acquisition ports , using the topological relationship between the final acquisition signal of the A and B two-phase current sensors and the switching state of the inverter, determine the manifestation of the current sampling error in the system, and obtain the relationship between the current sampling value containi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com