A Method for Estimating Vertical Stiffness of Locomotive Body

A locomotive and car body technology, applied in the field of locomotive body vertical stiffness estimation, can solve the problems of long time, low calculation accuracy, no clear method, etc., and achieve the effect of high accuracy and fast estimation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

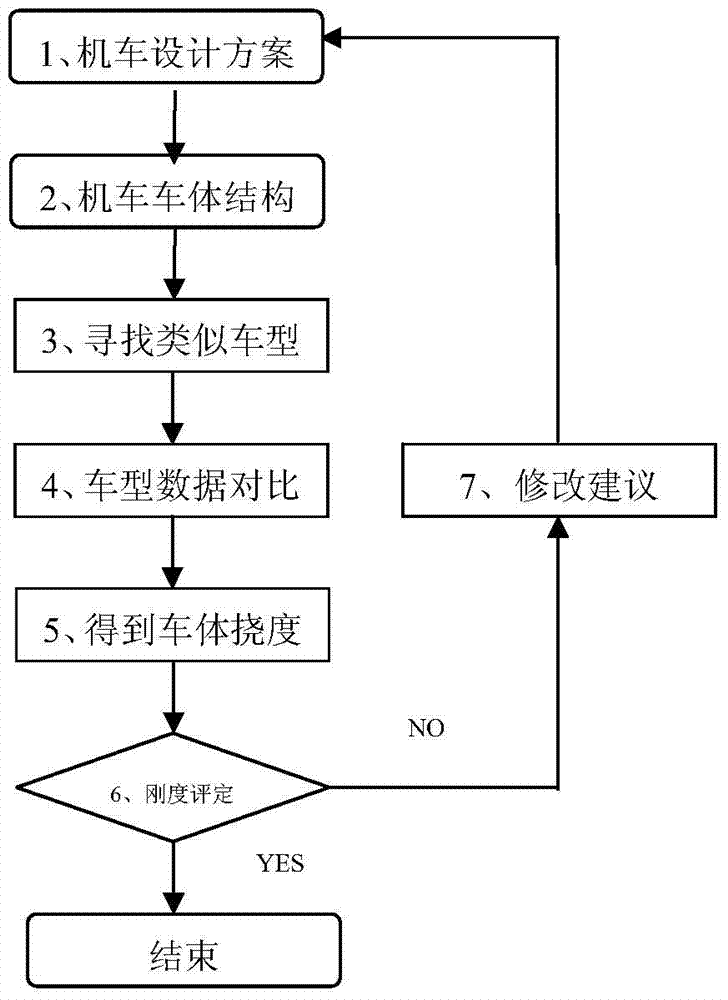

[0027] A method for estimating the vertical stiffness of a locomotive body, such as figure 1 shown, including the following steps:

[0028] Step 1. Locomotive Design Scheme

[0029] According to the requirements of the locomotive research project or the requirements of the locomotive product contract, a preliminary design of the locomotive is carried out to determine the overall design scheme of the locomotive, and the scheme data is the basis for stiffness estimation.

[0030] Step 2. Car body plan

[0031] According to the overall design plan of the locomotive, determine the car body plan, which includes: side beam length, side beam form, beam section parameters, car body section, equipment layout, etc., and then determine the specific data of the following main parameters of the design model: front and rear side bearings Parameters such as center distance L1, vehicle body and upper load F1, section moment of inertia I1, etc.

[0032] In the design of locomotives, there a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com