Oil-cooled motor with oil path structure and motor oil path cooling system

A cooling system and oil circuit technology, which is applied in the motor oil circuit cooling system and oil-cooled motor field, can solve the problems such as the inability to match the gearbox, achieve the effect of improving power density and reliability, less structural changes, and less structural improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

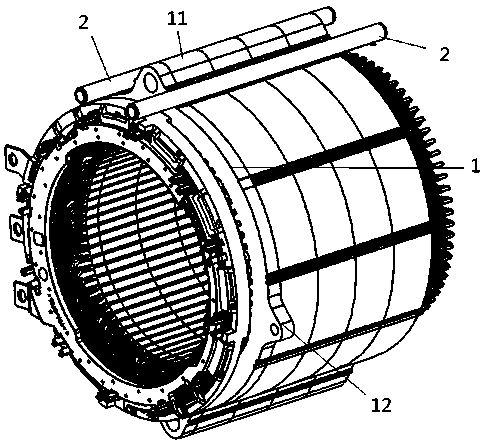

[0037] Figure 4 , 5 Two stator core structures are shown respectively. In one embodiment, there are two armature main assembly ears 11 , and the two armature main assembly ears 11 are symmetrically arranged on the stator core 1 . There are two auxiliary armature mounting ears 12, and the two auxiliary armature mounting ears 12 are arranged symmetrically and on the symmetrical planes of the two main armature mounting ears 12 (refer to Figure 4 ). Each armature main assembly ear has a mounting hole at both ends of the stator core. by Figure 4As an example, the formation of the stator core will be described. Considering the saving of stator punching materials, the blanking of the stator punching sheet is a square, making full use of the maximum diagonal size of the square, one kind of punching sheet symmetrically protrudes from the two armature main assembly ears, and the second type of punching sheet is in the first Two armature auxiliary lugs are added to the symmetric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com