Anode gas purification control method for proton exchange membrane fuel cell

A proton exchange membrane and anode gas technology, which is applied in the direction of fuel cells, fuel cell additives, electrolyte treatment of solid electrolyte batteries, etc., can solve the problems of difficult selection of purification time, waste of hydrogen, etc., to reduce the number of purification times and control the duration of purification time, and the effect of improving the utilization rate of hydrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

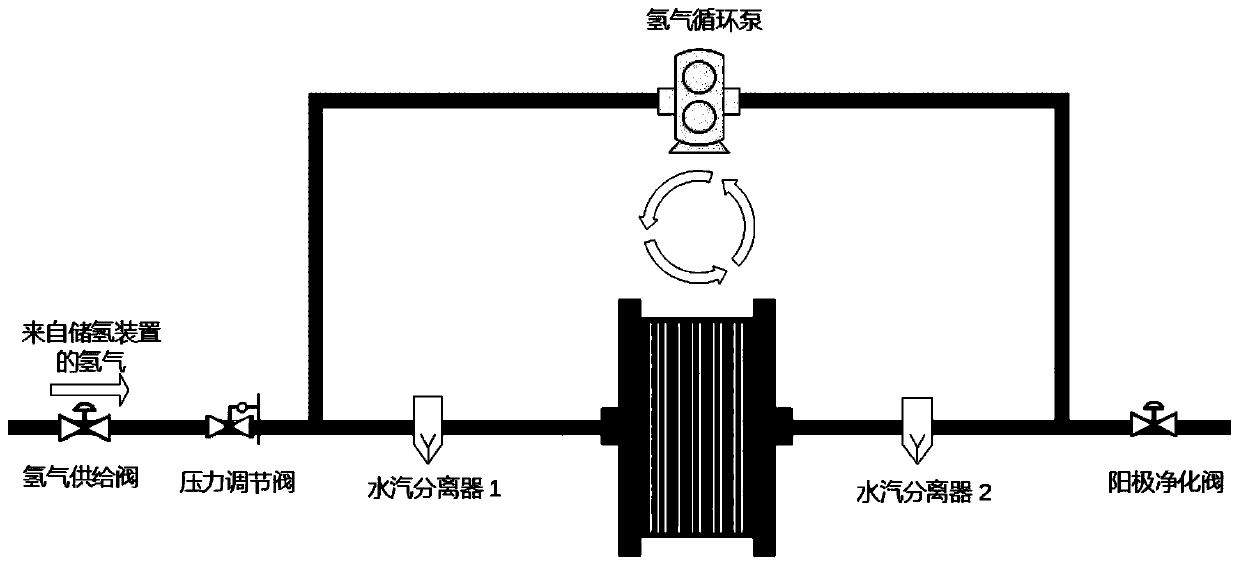

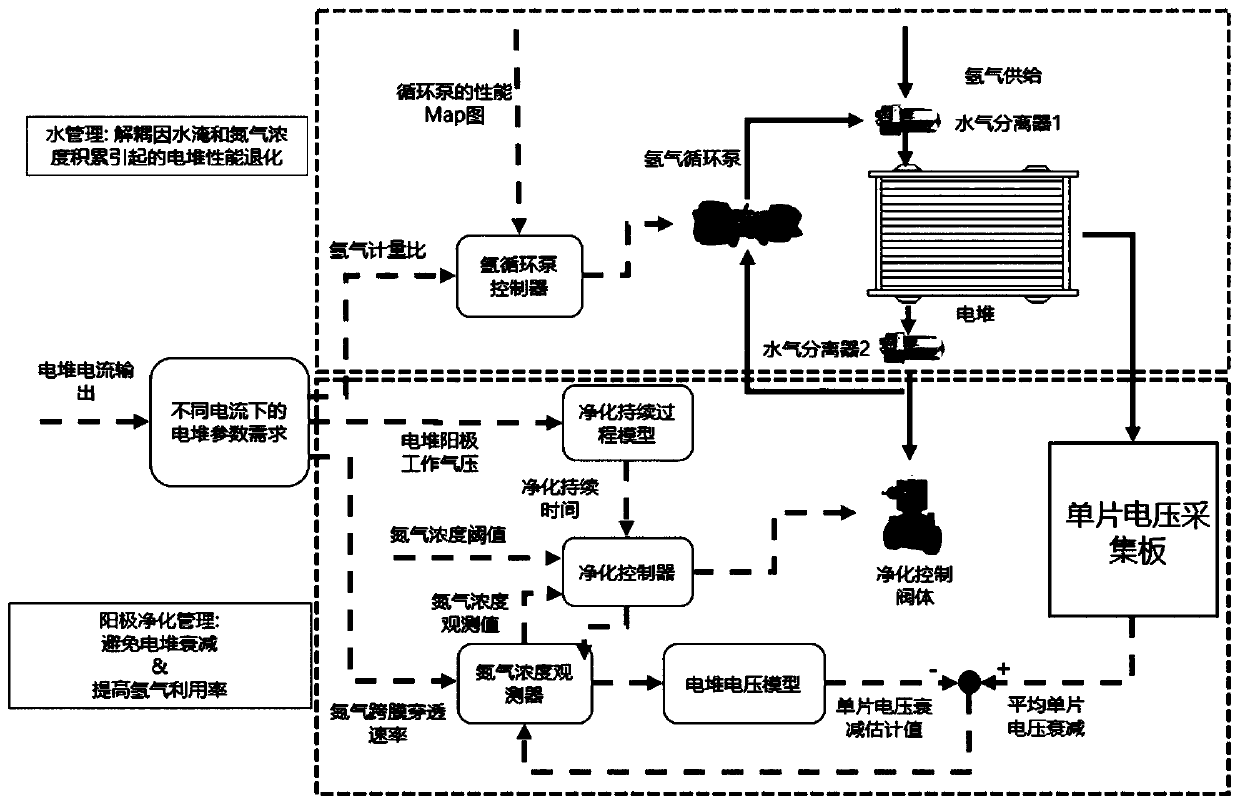

[0030] according to figure 1 The schematic diagram of the structure shown builds the experimental platform. And according to the anode purification process described in the summary of the invention, it is realized in the program of the experimental bench.

[0031] According to the embodiment that the method of content of the present invention implements completely is as follows:

[0032] The stack used in this embodiment is a 3kW proton exchange membrane fuel cell stack.

[0033] During the experiment, the cathode was given a constant metering ratio of 2.5, and the oxygen content of the test environment was 21%. The temperature was controlled at 65°C ± 0.5°C.

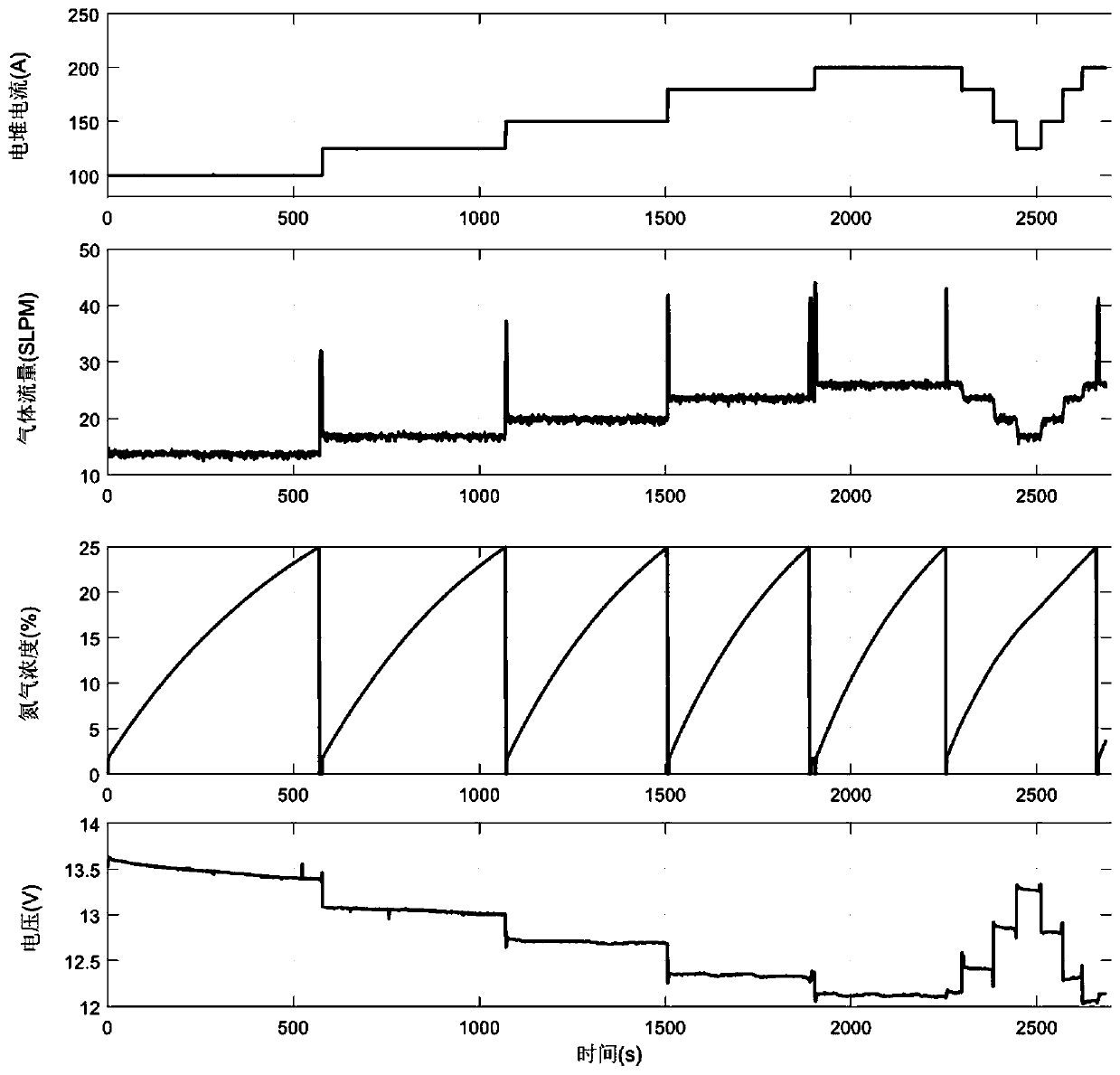

[0034] Example implementation results such as image 3 shown. Using the operating conditions of the system after the present invention in a working condition cycle, the two situa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com