A lithium battery device for automobiles

A lithium battery and automobile technology, applied in the automotive field, can solve the problems of being unable to play a waterproof role and affecting the safety of automobile lithium battery packs, and achieve excellent waterproof effects, high comprehensive performance, and high operational stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

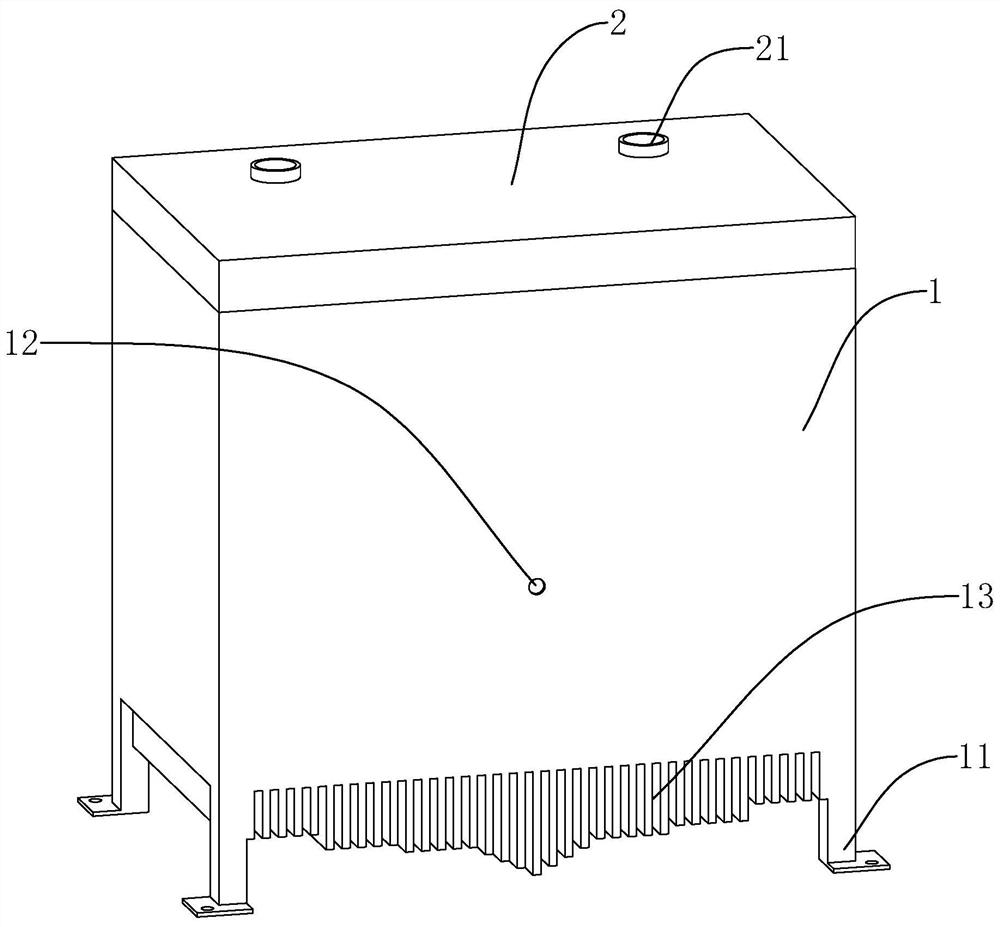

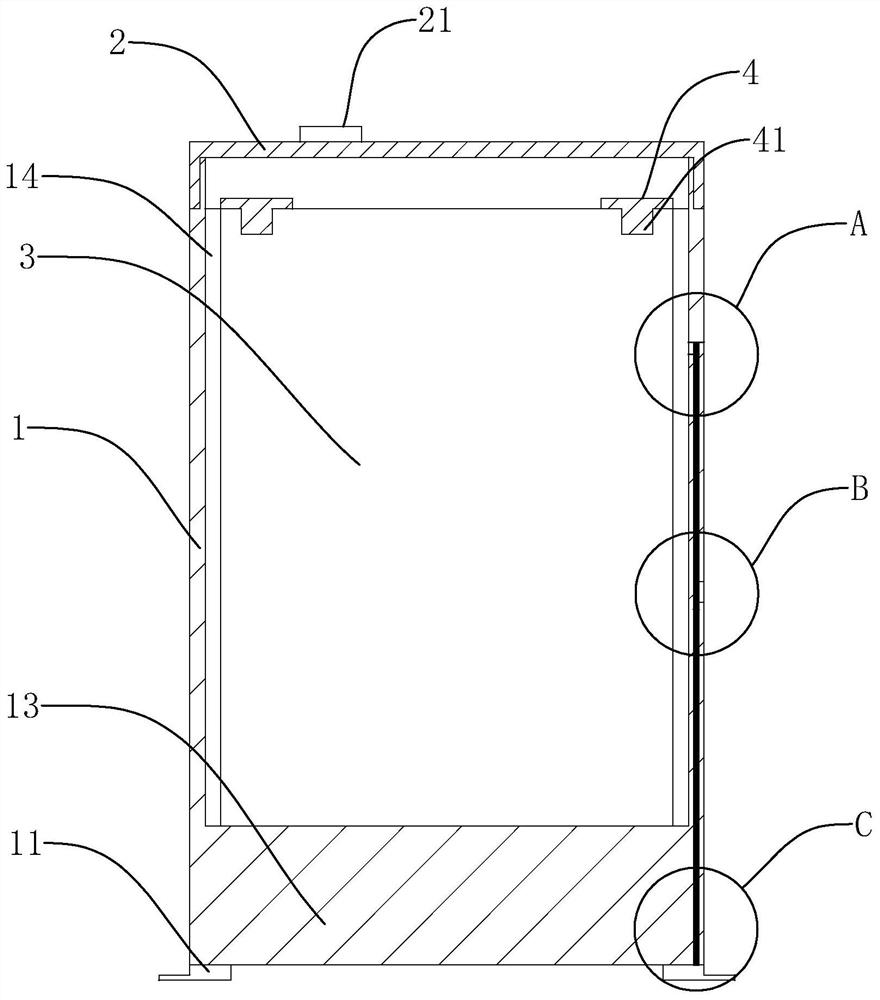

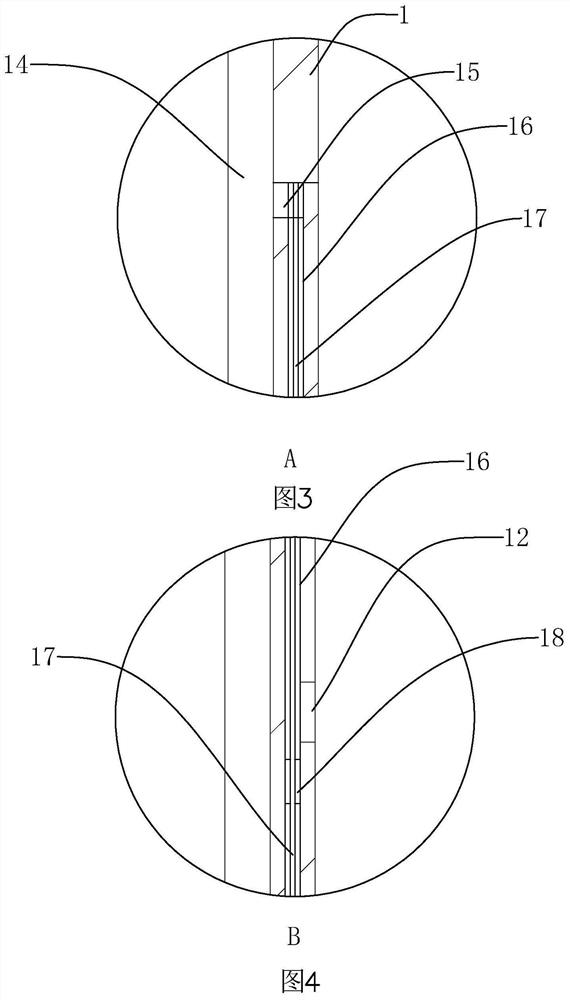

[0046] like figure 1 As shown, a lithium battery device for an automobile includes an outer casing. The outer casing serves to keep the inside of the lithium battery device dry. It should be noted that the outer casing includes the lower casing 1 and the upper cover 2 matched with the top end of the lower casing 1 . At the bottom of the lower case 1 are a plurality of heat dissipation plates 13 arranged at intervals and fixing feet 11 for fixing the outer case. When the lithium battery device is installed and fixed by the fixing feet 11, the interior of the outer case is separated by the heat dissipation plate 13 at the same time. The heat of the battery is exchanged with the outside of the outer casing, so as to achieve the effect of affecting the life of the lithium battery device caused by the accumulation of heat inside the outer casing. The upper cover 2 is provided with a power interface 21 , and the power cord is sealed and connected to the interior of the lithium bat...

Embodiment 2

[0057] The difference between Example 2 and Example 1 is that the adhesive layer in Example 2 includes the following components by weight: 14 parts of polyethylene; 14 parts of glycidyl butyl ether; 2 parts of rubber powder; deionized water 150 servings.

[0058] And the preparation method of the adopted battery separator comprises the following steps:

[0059] Step 1. Mix 14 parts of polyethylene, 14 parts of glycidyl butyl ether; 2 parts of rubber powder; and 150 parts of deionized water to obtain an adhesive with a viscosity between 40-80 cP;

[0060] Step 2. Control the temperature of the adhesive at 48°C, put the non-woven base layer in the adhesive for 30 minutes, take it out, dry at 380°C, and form an adhesive layer on both sides of the non-woven base layer to obtain a diaphragm coarse material;

[0061] Step 3, rolling the raw material of the separator through a calender, and controlling the temperature of the calender to be 72° C. to obtain a battery separator.

Embodiment 3

[0063] The difference between Example 2 and Example 1 is that the adhesive layer in Example 2 includes the following components by weight: 16 parts of polyethylene; 16 parts of glycidyl butyl ether; 3 parts of rubber powder; deionized water 180 copies.

[0064] And the preparation method of the adopted battery separator comprises the following steps:

[0065] Step 1. Mix 16 parts of polyethylene, 16 parts of glycidyl butyl ether; 3 parts of rubber powder; and 180 parts of deionized water to obtain an adhesive with a viscosity between 40-80cP;

[0066] Step 2. Control the temperature of the adhesive at 48°C, put the non-woven base layer in the adhesive for 30 minutes, take it out, dry at 53°C, and form an adhesive layer on both sides of the non-woven base layer to obtain a diaphragm coarse material;

[0067] Step 3, rolling the raw material of the separator through a calender, and controlling the temperature of the calender to be 76° C. to obtain a battery separator.

[0068...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com