Halogen-free low-smoke high-flame-retardant high-oxygen-isolation cable material for power cable, and preparation method thereof

A power cable, high flame retardant technology, used in circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problems of poor flame retardant and fire resistance, unsatisfactory extrusion process, and poor forming. Superior processing performance, superior processing performance, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

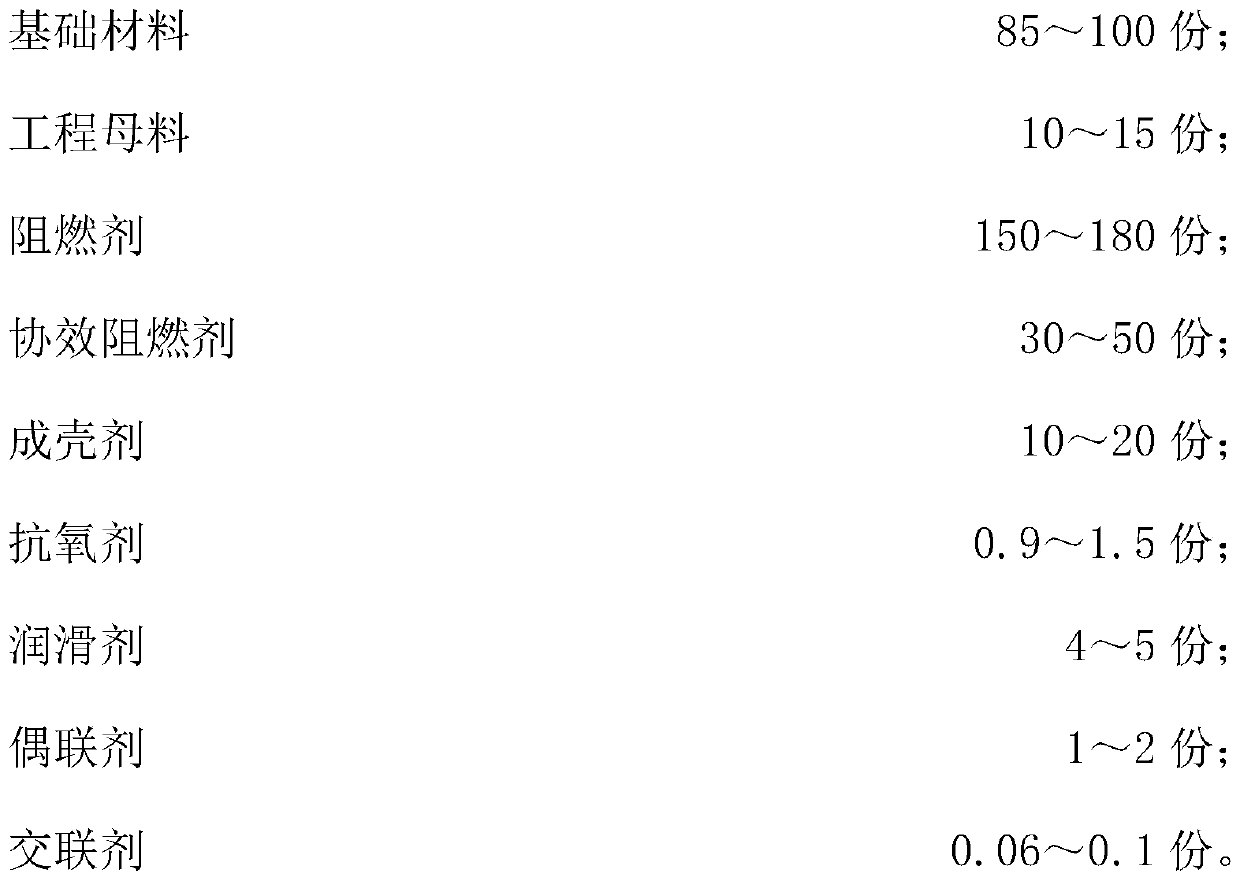

[0063] The second aspect of the present invention provides a method for preparing the halogen-free, low-smoke, high flame-retardant and high-oxygen barrier cable material for power cables according to the present invention. The preparation method includes the following steps:

[0064] First prepare the components of the cable material according to the ratio of parts by weight described in the first aspect of the present invention, then dissolve the crosslinking agent in the coupling agent; then dissolve the flame retardant, synergistic flame retardant , shell forming agent, antioxidant, lubricant and dissolved coupling agent and crosslinking agent, add to the high-speed mixer and stir at high speed for about 10 minutes, the temperature is controlled at about 60°C; then add the stirred material to the banburying In the mixing machine, add the basic material and engineering masterbatch into the internal mixer, wait for the temperature of the internal mixing material to reach 145-...

Embodiment

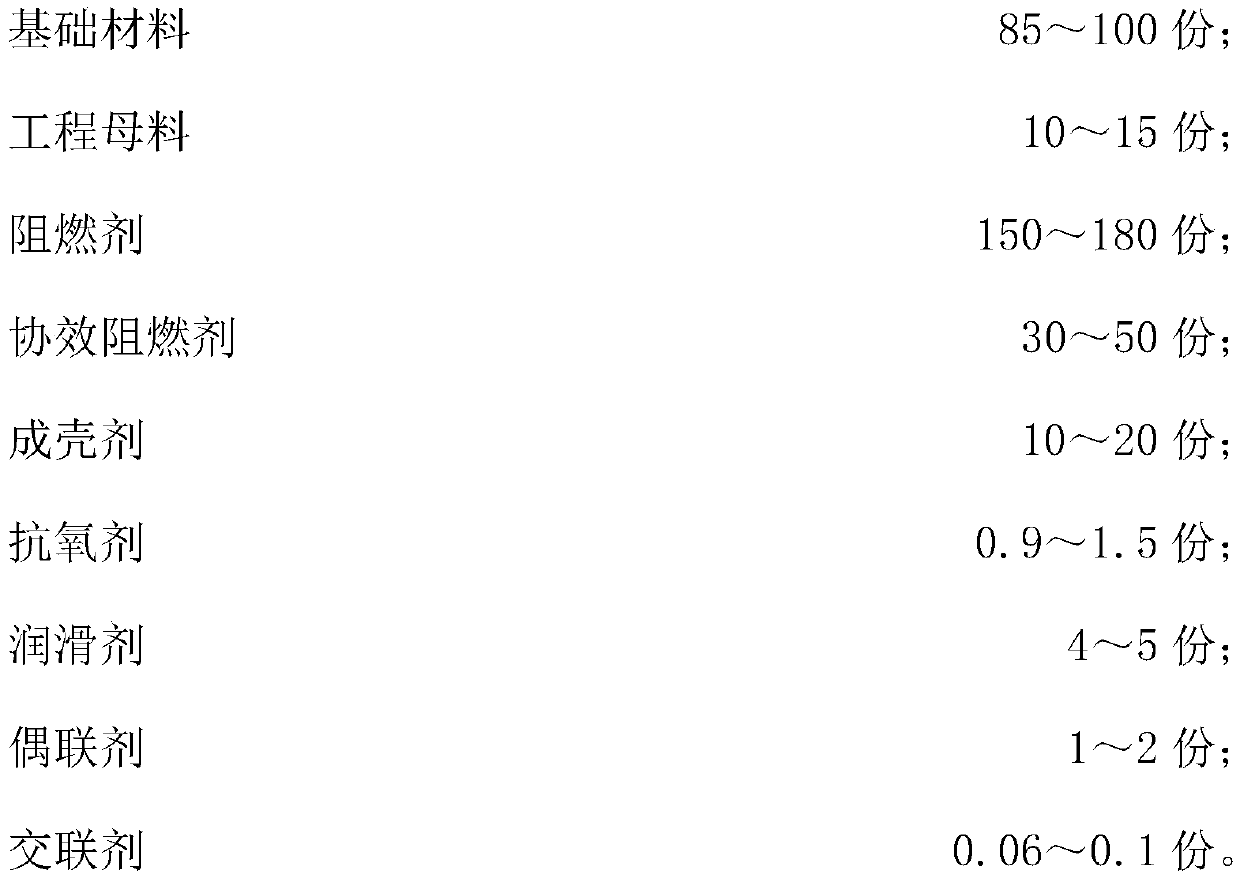

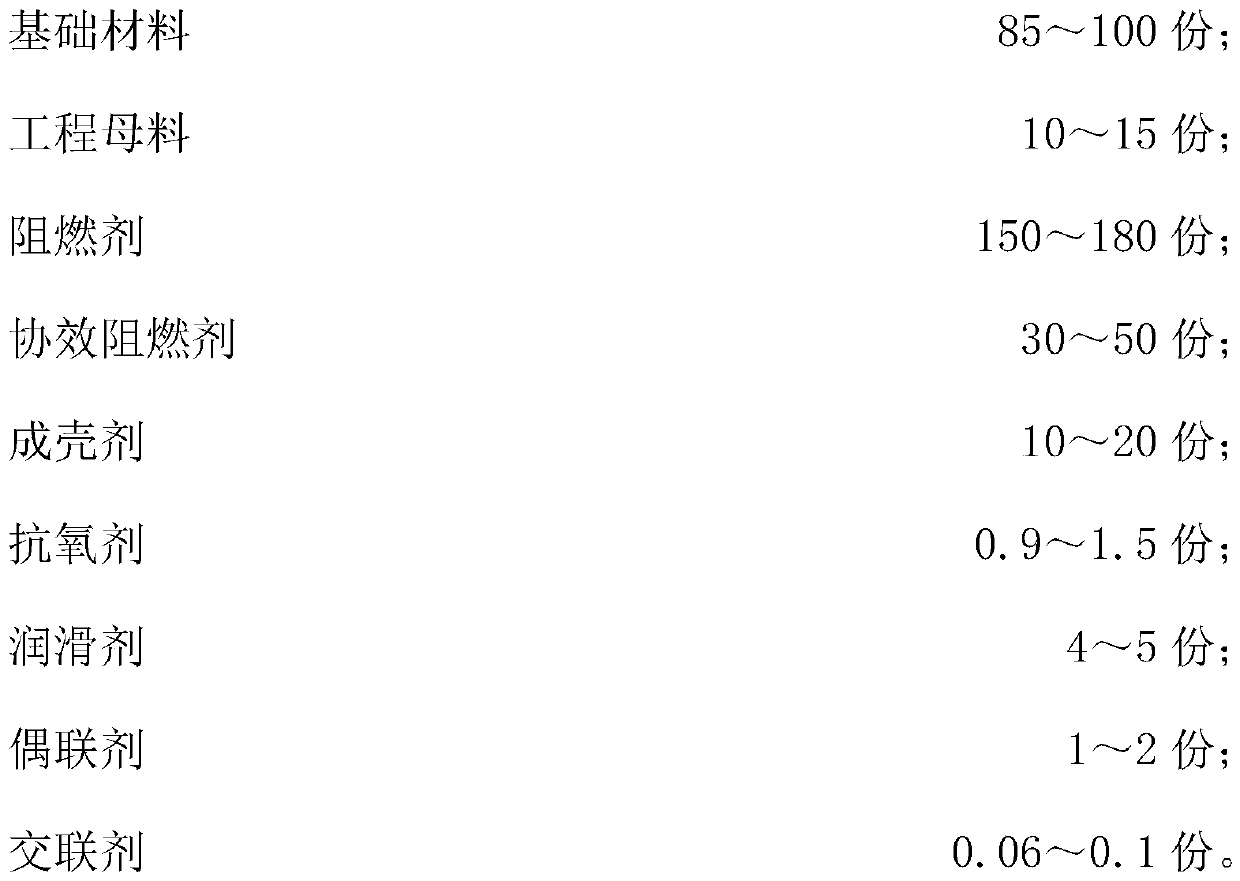

[0070] The name of each component and the parts by weight of each component are shown in Table 1 below.

[0071] Table 1:

[0072] raw material Example 1 Example 2 Example 3 EVA 70 75 80 MLLDPE 25 10 15 PE grafted maleic anhydride 15 9 POE grafted maleic anhydride 15 6 Aluminum hydroxide 120 75 magnesium hydroxide 60 150 100 Zinc borate 30 20 Antimony trioxide 35 20 25 Shell former 18 12 15 Antioxidant 1010 1 0.6 0.8 Antioxidant DLTDP 0.5 0.3 0.4 silicone 4 3 4 polyethylene wax 2 1 A silane coupling agent 1 2 1.5 Cross-linking agent DCP 0.06 0.1 0.09 total 349.56 320 352.79

[0073] The preparation method of the above-mentioned invention, it comprises the following processing steps:

[0074] First, dissolve the crosslinking agent in the coupling agent according to the parts by weight; then prepare other materials according to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com