A kind of preparation method of microporous high temperature resistant lightweight refractory brick

A technology of high temperature resistant refractory bricks, which is applied in the field of preparation of microporous high temperature resistant lightweight refractory bricks, can solve the problems of corrosion resistance, high temperature resistance, low strength, etc. , the effect of low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

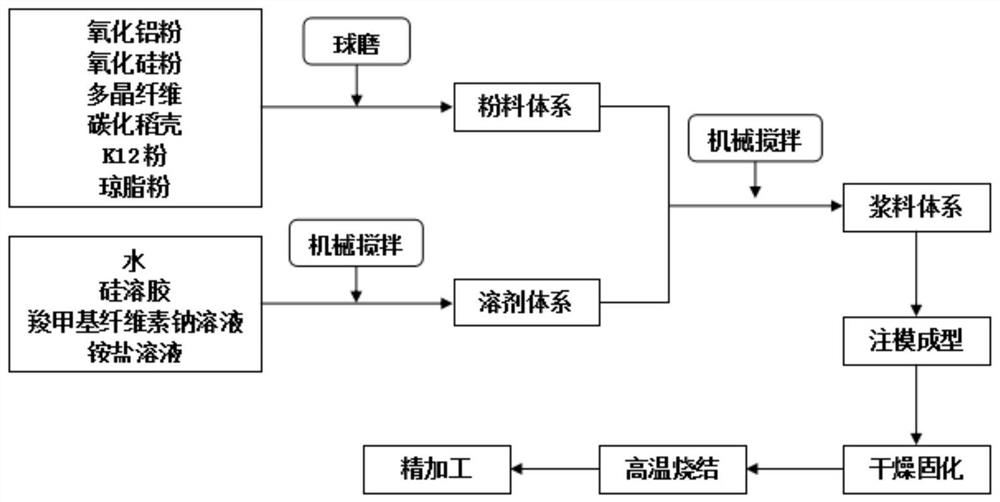

Method used

Image

Examples

Embodiment approach 1

[0025] 1. Weigh 3.8kg of alumina powder, 570g of polycrystalline mullite fiber, 750g of silicon powder, 300g of carbonized rice husk, 60g of K12 powder, and 100g of agar powder, add them to a ball mill and mix them for 1 hour, mix well and take out for use;

[0026] 2. Weigh 1.2kg of 80°C water for use, weigh 1.0kg of silica aerosol, 130ml of sodium carboxymethyl cellulose solution, and 70ml of ammonium salt solution, mix them into 80°C water, and use a mixer at 100 rpm, Stir slowly for 5min to make a mixed solvent;

[0027] 3. Gradually add the uniformly mixed powder into the mixed solvent. During the powder addition process, keep the mixer stirring slowly (rotating speed 100 rpm). After the powder is completely added to the mixed solvent, increase the mixer speed (rotating speed 700 rpm). Stir at high speed for 15 minutes until the slurry foams sufficiently;

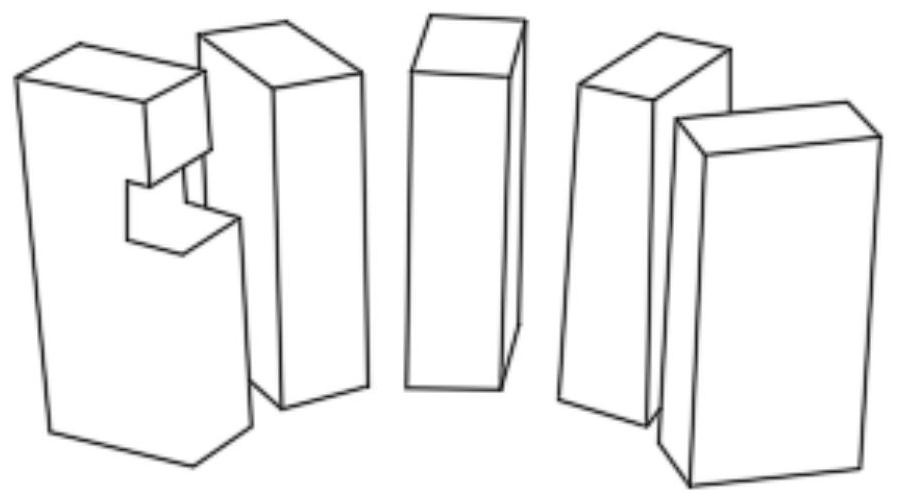

[0028] 4. Pour the foamed slurry into a mold with a size of 480*165*90mm, let it stand for 24 hours, cool the slurr...

Embodiment approach 2

[0032] 1. Weigh 4.32kg of alumina powder, 640g of polycrystalline mullite fiber, 840g of silicon powder, 380g of carbonized rice husk, 80g of K12 powder, and 110g of agar powder, add them into a ball mill and mix them for 2 hours, mix well and take out for use;

[0033] 2. Weigh 1.3kg of 80°C water for use, weigh 1.1kg of silica aerosol, 150ml of sodium carboxymethyl cellulose solution, and 80ml of ammonium salt solution, mix them into 80°C water, and use a mixer at a speed of 100 rpm. Stir slowly for 5min to make a mixed solvent;

[0034] 3. Gradually add the uniformly mixed powder into the mixed solvent. During the powder addition process, keep the mixer stirring slowly (rotating speed 200 rpm). After the powder is completely added to the mixed solvent, increase the mixer speed (rotating speed 900 rpm). Stir at high speed for 20 minutes until the slurry foams sufficiently;

[0035] 4. Pour the foamed slurry into a mold with a size of 960*125*80mm, and let it stand for 24 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com