Multi-station macromolecular vacuum hot press

A vacuum hot pressing and polymer technology, applied in the field of hot press equipment, can solve problems such as harsh structural design, stagnant development and research of multi-station hot press machines, and inability to realize batch hot press processing, etc., to achieve compact structure , Good consistency, small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further understand the content, features and effects of the present invention, the following examples are given in detail.

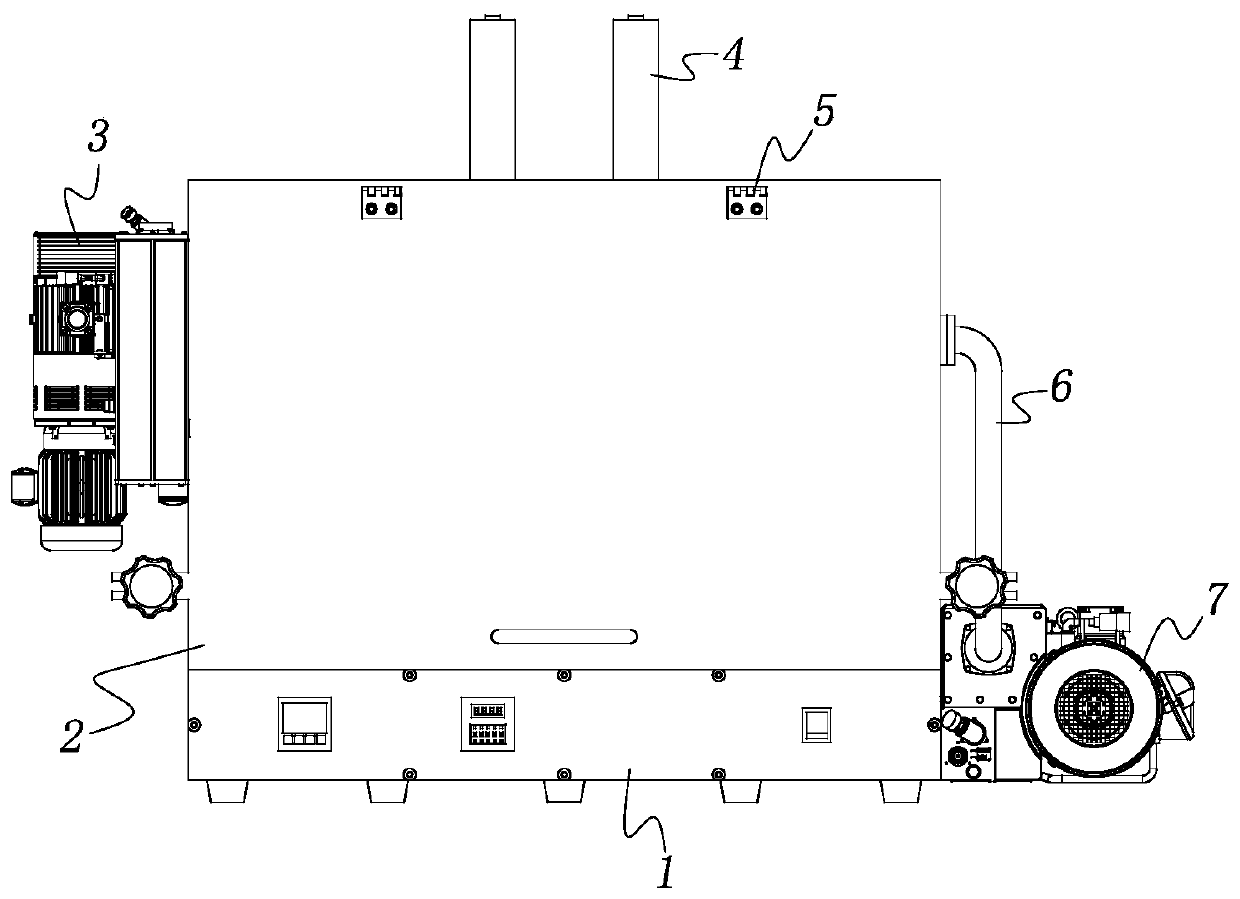

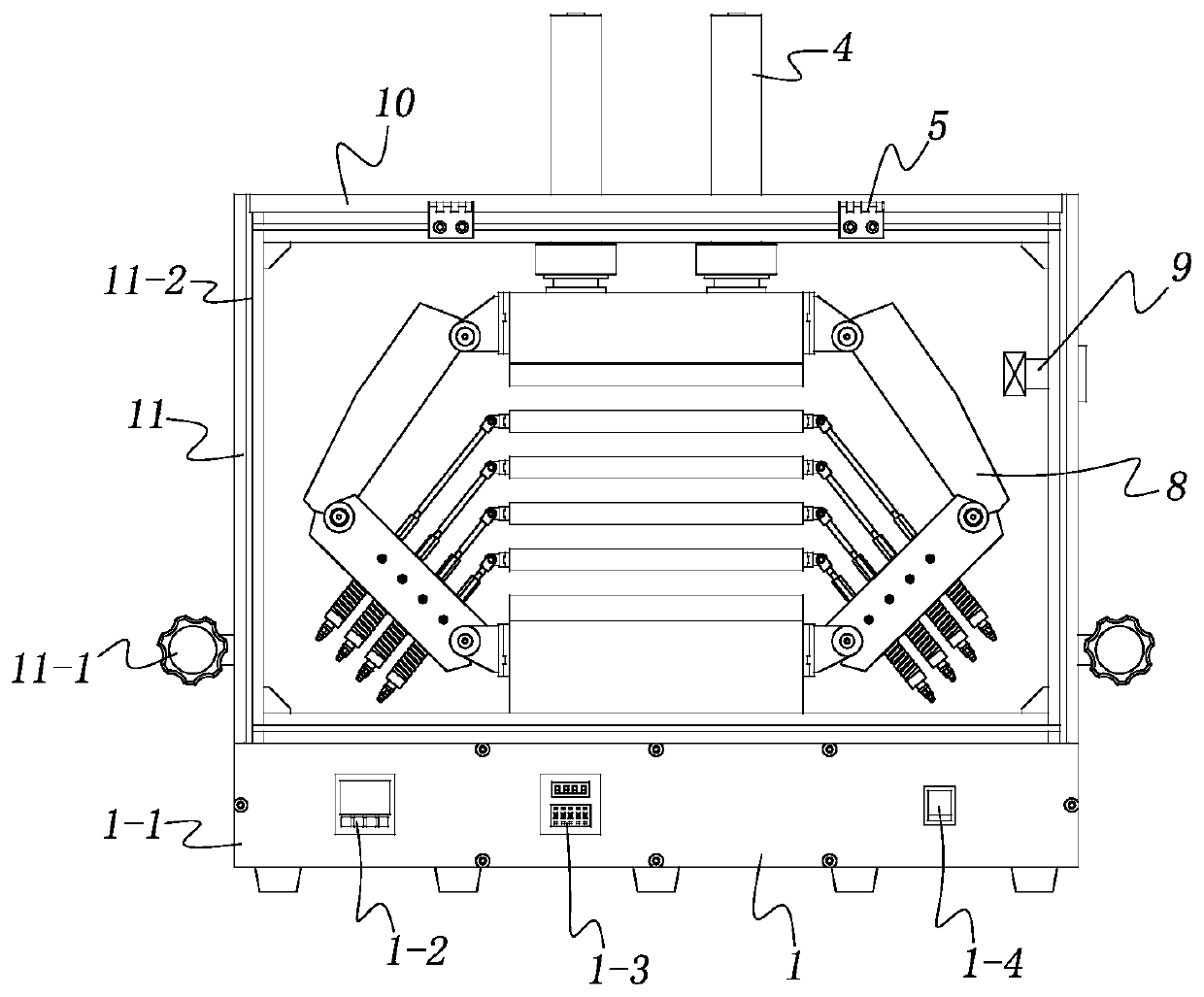

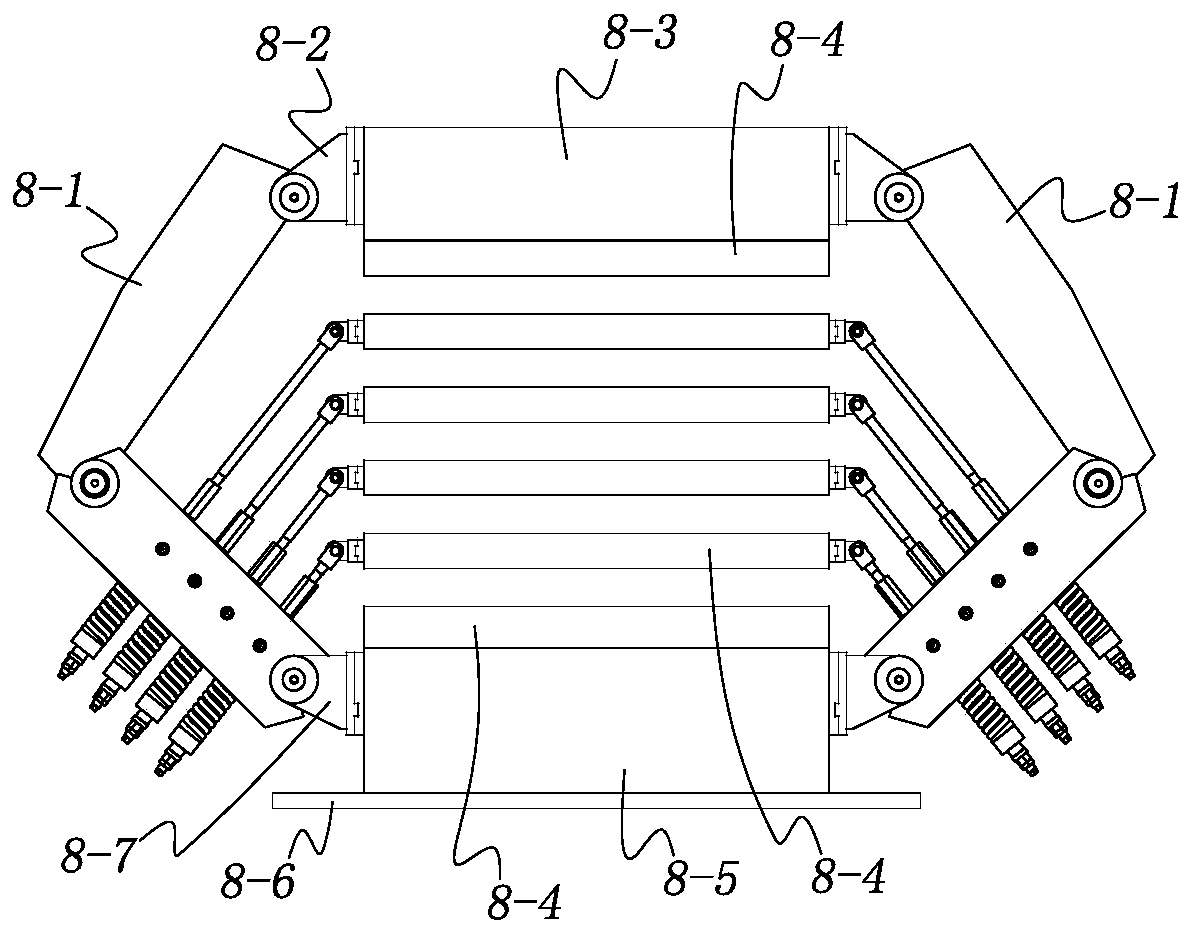

[0026] See figure 1 with figure 2 , the multi-station polymer vacuum heat press of the present invention comprises a support bottom shell 1, an inner frame 11 is installed on the support bottom shell 1, and box boards are provided on the top, back, left and right sides of the inner frame 11 10. A box door 2 is hingedly installed on the front part of the inner frame 11. After the box door 2 is closed, each box plate 10, the box door 2 and the top plate supporting the bottom shell 1 form a sealed box body.

[0027] Wherein, the inner frame 11 is built with metal profiles, and the box panels 10 on the top, back, left and right sides are all cut from thick metal plates and welded to the inner frame 11. The bottom of the inner frame 11 is connected to the supporting bottom. The top plate of the shell 1 is sealed and welded, the left part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com