Axial liquid flushing micro electrolytic machining device and machining method

A micro-electrolysis and processing device technology, applied in the direction of electrochemical processing equipment, the supply of processing working medium, metal processing equipment, etc., can solve the problems of limited processing depth, reduced processing accuracy, and difficulty in discharging electrolytic products, and achieve low cost , high efficiency and low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

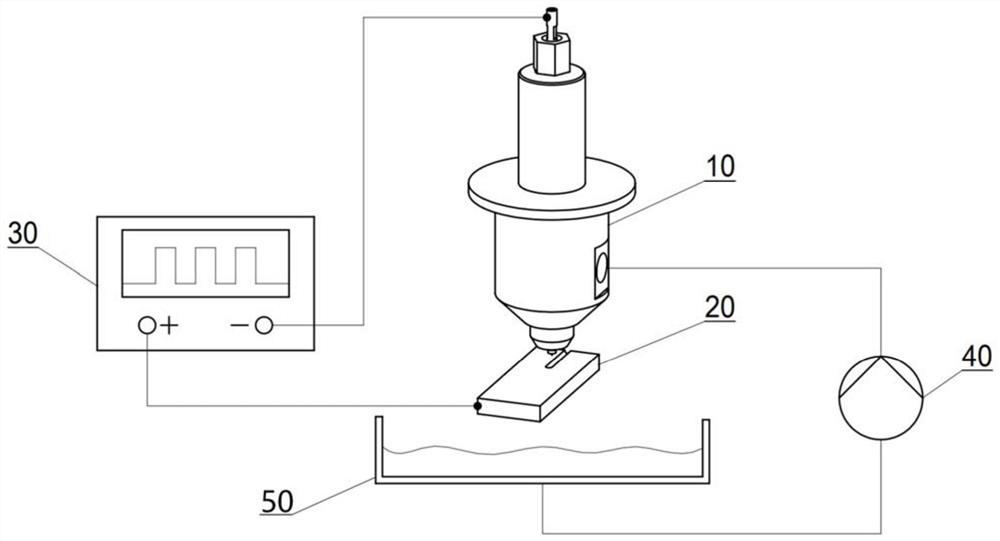

[0050] A micro-electrolytic processing device for axial liquid flushing, the processing device includes an axial liquid flushing tool head 10 , a workpiece anode 20 , a pulse power supply 30 , a booster pump 40 and an electrolyte tank 50 .

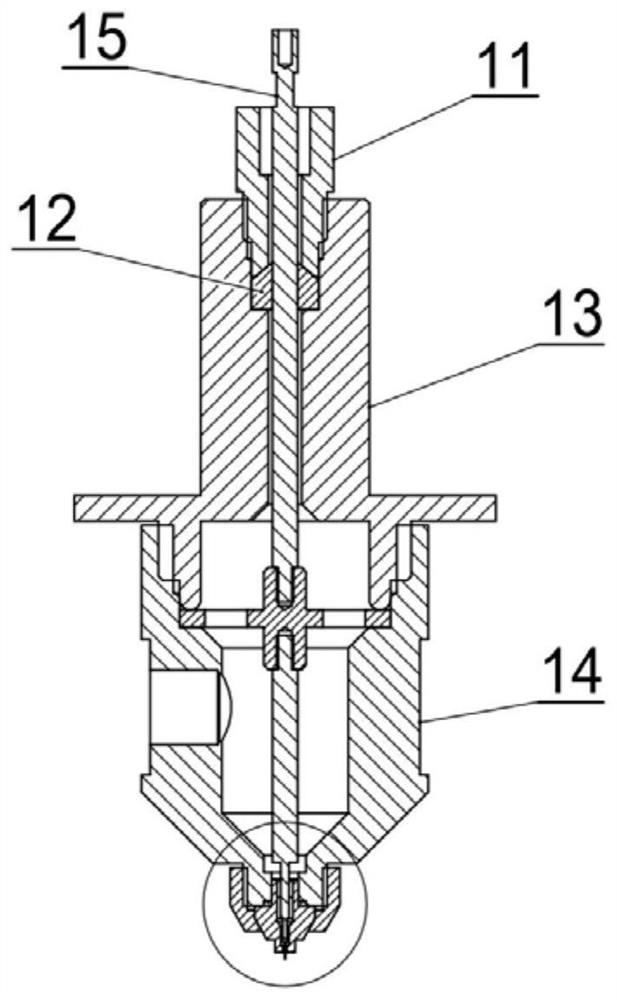

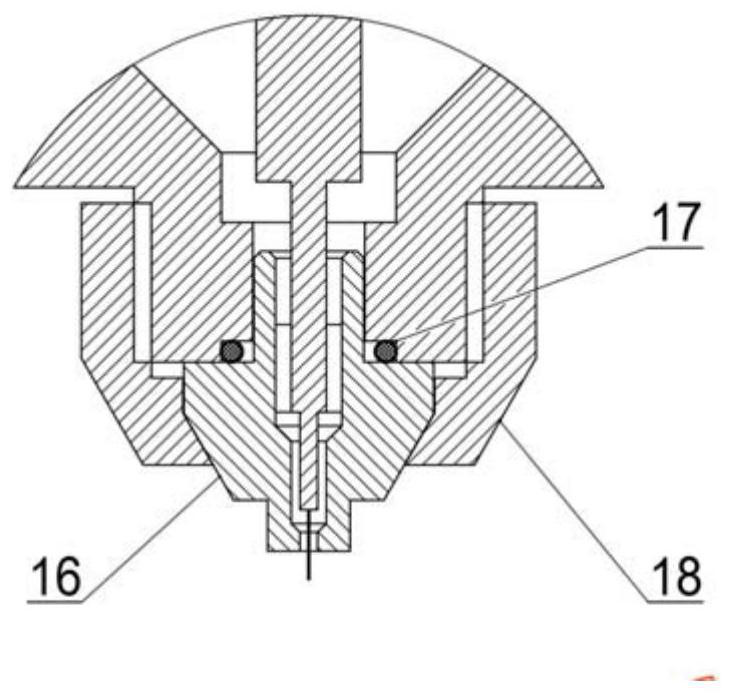

[0051] In a preferred embodiment, the axial flushing tool head 10 includes an upper cavity 13 , a lower cavity 14 , a combined electrode 15 , a nozzle 16 , and a pressing member II18.

[0052] The bottom of the upper cavity 13 is open, and the top of the upper cavity 13 has a through hole.

[0053]The axial flushing tool head 10 also includes a water stopper 12. The through hole of the upper cavity 13 is provided with an internal thread section, and the bottom of the internal thread section is provided with a water stopper annular step. The water stopper 12 is installed On the annular step of the water stopper in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com