Protein microcapsules for targeted inhibition of small intestinal amylase and preparation method

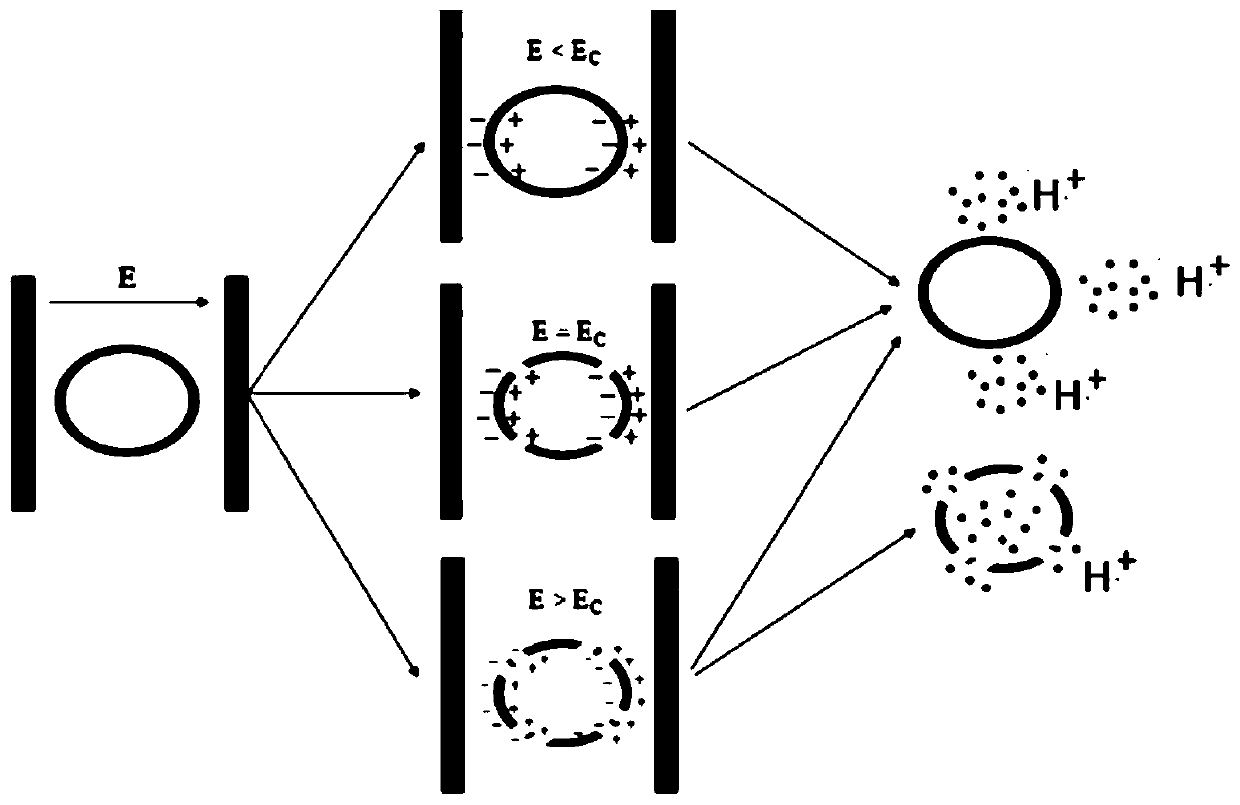

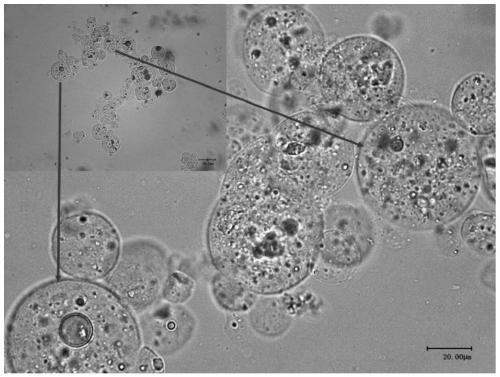

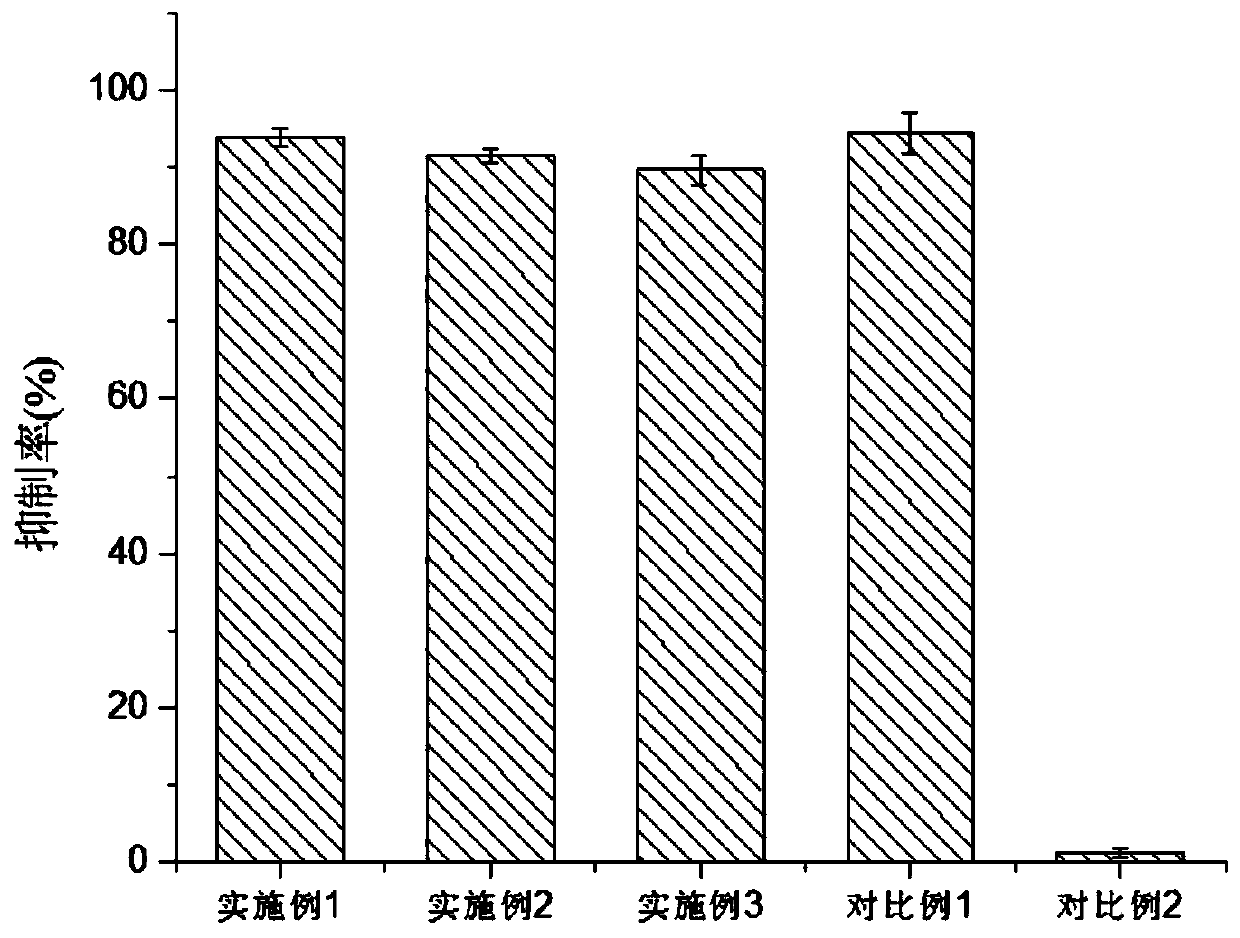

A protein and amylase technology, applied in the field of nutrition and health, to achieve the effect of uniform shape, inhibition of activity, and small and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A protein microcapsule capable of targeting and inhibiting intestinal amylase and a preparation method thereof. Specific steps are as follows:

[0045] (1) Take 100 parts each of wheat flour, rye flour, highland barley flour, sorghum flour and barley flour, respectively disperse them in 1000 parts of deionized water containing 2% NaCl, extract at room temperature for 2 hours, centrifuge (9600g, 10min) to get the supernatant , add ammonium sulfate powder until its saturation is 75%, let it stand for 2h, centrifuge (9600g, 10min) to get the precipitate, dialyze and desalt after reconstitution, and vacuum dry to prepare wheat extract, rye extract, highland barley extract, Sorghum extract and barley extract are compounded according to the content ratio of 5:10:1:5:1 to obtain the grain extract.

[0046] (2) Dissolve 5 parts of cereal extract and 10 parts of polysaccharide in 400 parts of deionized water. Add 1.3 parts of calcium carbonate powder to make it evenly disperse...

Embodiment 2

[0051] A protein microcapsule capable of targeting and inhibiting intestinal amylase and a preparation method thereof. Specific steps are as follows:

[0052] (1) Take 100 parts each of wheat flour, rye flour, highland barley flour, sorghum flour and barley flour, disperse them in 1000 parts of deionized water containing 5% NaCl, extract at room temperature for 2 hours, and centrifuge (9600g, 10min) to get the supernatant , add ammonium sulfate powder until its saturation is 80%, let it stand for 2h, centrifuge (9600g, 10min) to get the precipitate, reconstitute and then dialyze and desalt, vacuum dry and extract respectively wheat extract, rye extract, highland barley extract and sorghum extract Grain extract and barley extract are compounded according to the content ratio of 2:8:3:5:5 to obtain the grain extract.

[0053] (2) Dissolve 4 parts of cereal extract and 4 parts of polysaccharide in 800 parts of deionized water. Add 0.8 parts of calcium carbonate powder to make i...

Embodiment 3

[0058] A protein microcapsule capable of targeting and inhibiting intestinal amylase and a preparation method thereof. Specific steps are as follows:

[0059] (1) Take 100 parts each of wheat flour, rye flour, highland barley flour, sorghum flour and barley flour, disperse them in 1000 parts of deionized water containing 0.5% NaCl, extract at room temperature for 2 hours, and centrifuge (9600g, 10min) to get the supernatant , add ammonium sulfate powder until its saturation is 85%, let it stand for 2h, centrifuge (9600g, 10min) to get the precipitate, dialyze and desalt after reconstitution, and vacuum dry to obtain rye extract, highland barley extract, sorghum extract and The barley extract is compounded according to the content ratio of 10:2:3:8:1 to obtain the grain extract.

[0060] (2) Dissolve 4 parts of cereal extract and 5 parts of polysaccharide in 500 parts of deionized water. Add 0..6 parts of calcium carbonate powder to make it evenly dispersed.

[0061] (3) Slo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com