A new type of high-efficiency lithium-sulfur battery cathode material and its preparation method

A technology for positive electrode materials and lithium-sulfur batteries, applied in battery electrodes, lithium batteries, positive electrodes, etc., can solve the problems of poor conductivity, low utilization rate, and shuttle effect of positive electrode materials, so as to improve conductivity, ease migration, and improve discharge The effect of specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

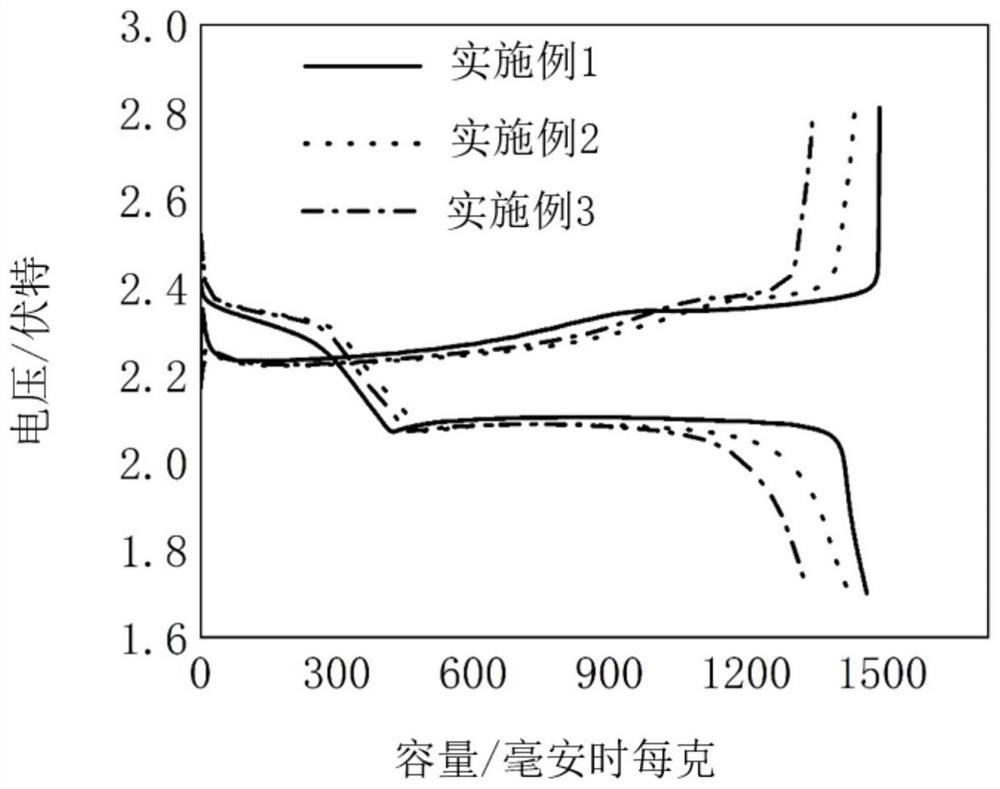

Embodiment 1

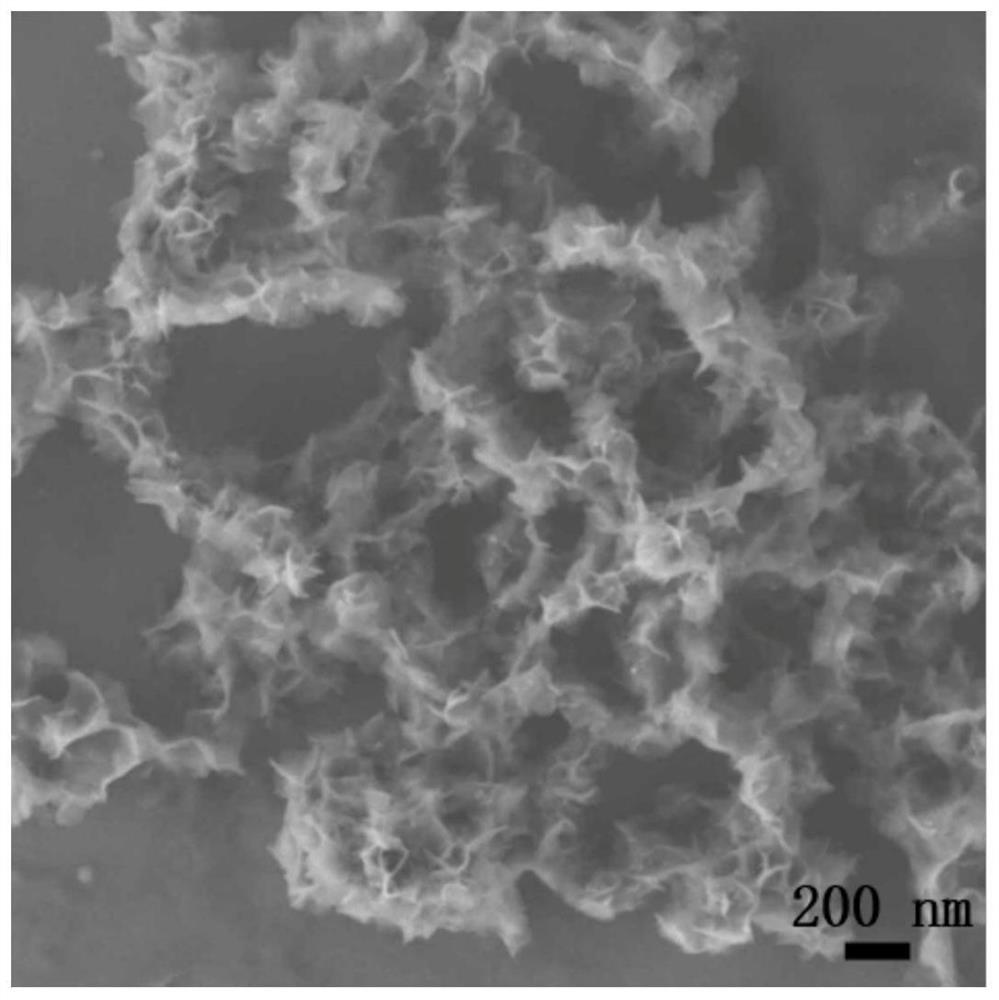

[0030] The novel high-efficiency lithium-sulfur battery cathode material is a CNT-ZnCo-LDH composite material. The CNT-ZnCo-LDH composite material is composed of layered zinc-cobalt double hydroxide ZnCo-LDH uniformly attached to the multi-walled carbon nanotube CNT.

[0031] The preparation method of the novel high-efficiency lithium-sulfur battery cathode material specifically comprises the following steps:

[0032] (1) Preparation of CNT-ZnO: First, dissolve 0.3g of zinc acetate in 55mL of anhydrous methanol, stir at 50°C until completely dissolved to obtain a zinc acetate solution, add the zinc acetate solution into a round bottom flask for oil bath, Insulate at 70°C; then add 0.2g of CNT to 35mL of anhydrous methanol, sonicate until completely dissolved, add the dissolved CNT solution to the above round bottom flask, stir at 70°C for 25min; finally add 0.25g of potassium hydroxide Add it into 45mL of anhydrous methanol, stir and heat on a 70°C heating plate, add the heat...

Embodiment 2

[0038] The preparation method of the novel high-efficiency lithium-sulfur battery cathode material specifically comprises the following steps:

[0039] (1) Preparation of CNT-ZnO: First, dissolve 0.2g of zinc acetate in 50mL of anhydrous methanol, stir at 40°C until completely dissolved to obtain a zinc acetate solution, add the zinc acetate solution to a round bottom flask for oil bath, Insulate at 65°C; then add 0.1g of CNT to 30mL of anhydrous methanol, sonicate until completely dissolved, add the dissolved CNT solution to the above round bottom flask, stir at 65°C for 20min; finally add 0.2g of potassium hydroxide Add it into 40mL of anhydrous methanol, stir and heat on a 65°C heating plate, add the heated potassium hydroxide solution dropwise into the above round bottom flask, stir at 65°C for 1h, centrifuge to collect the precipitate, and use The precipitate was washed three times with anhydrous methanol, and dried at 60°C for 13 hours to obtain CNT-ZnO;

[0040] (2) Pr...

Embodiment 3

[0044] The preparation method of the novel high-efficiency lithium-sulfur battery cathode material specifically comprises the following steps:

[0045] (1) Preparation of CNT-ZnO: First, dissolve 0.4g of zinc acetate in 60mL of anhydrous methanol, stir at 60°C until completely dissolved to obtain a zinc acetate solution, add the zinc acetate solution into a round bottom flask for oil bath, Insulate at 75°C; then add 0.3g of CNT to 40mL of anhydrous methanol, sonicate until completely dissolved, add the dissolved CNT solution to the above round bottom flask, stir at 75°C for 30min; finally add 0.3g of potassium hydroxide Add it into 50mL of anhydrous methanol, stir and heat on a 75°C heating plate, add the heated potassium hydroxide solution dropwise into the above-mentioned round bottom flask, stir at 75°C for 3h, centrifuge to collect the precipitate, and use The precipitate was washed three times with anhydrous methanol, and dried at 70°C for 14 hours to obtain CNT-ZnO;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com