Test device and method for observing behavior of flowing boiling bubbles in micro-channel

A test device and microchannel technology, applied in the field of physical measurement, can solve the problems of lack of bubble dynamics, achieve the effect of convenient flow of working fluid, reduce test time, and facilitate research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

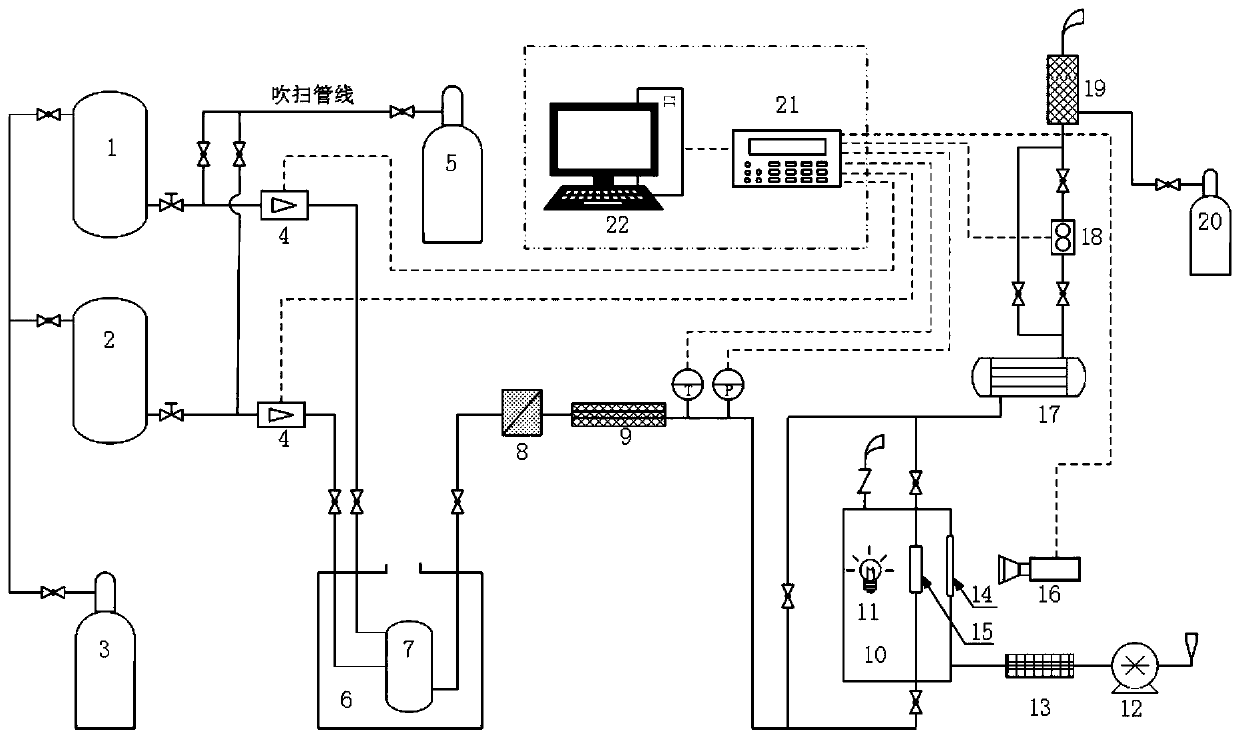

[0039] In a typical embodiment of the present invention, as figure 1 As shown, a test device for observing the behavior of flowing and boiling bubbles in a microchannel includes a liquid dispensing mechanism, a purging mechanism, an observation mechanism, a venting mechanism, a data monitoring and collection mechanism, and pipes, pipe fittings, valves, etc. connecting various equipment. The liquid mechanism is connected to the observation mechanism, and the liquid dispensing mechanism can provide the observation mechanism with a mixed working fluid composed of precise components; the purging mechanism is connected to all the pipelines in this embodiment, and all pipelines here include connections for various The pipeline between the mechanism and the microchannel, as well as the pipeline of the microchannel itself, the purging mechanism blows nitrogen into the test mechanism and the pipeline before and after the test, and the observation mechanism is used for the observation of...

Embodiment 2

[0066] This embodiment discloses a test method for observing the behavior of flowing and boiling bubbles in a microchannel. It should be stated first that all valves in the test device are closed before a set of tests starts; the following steps are included:

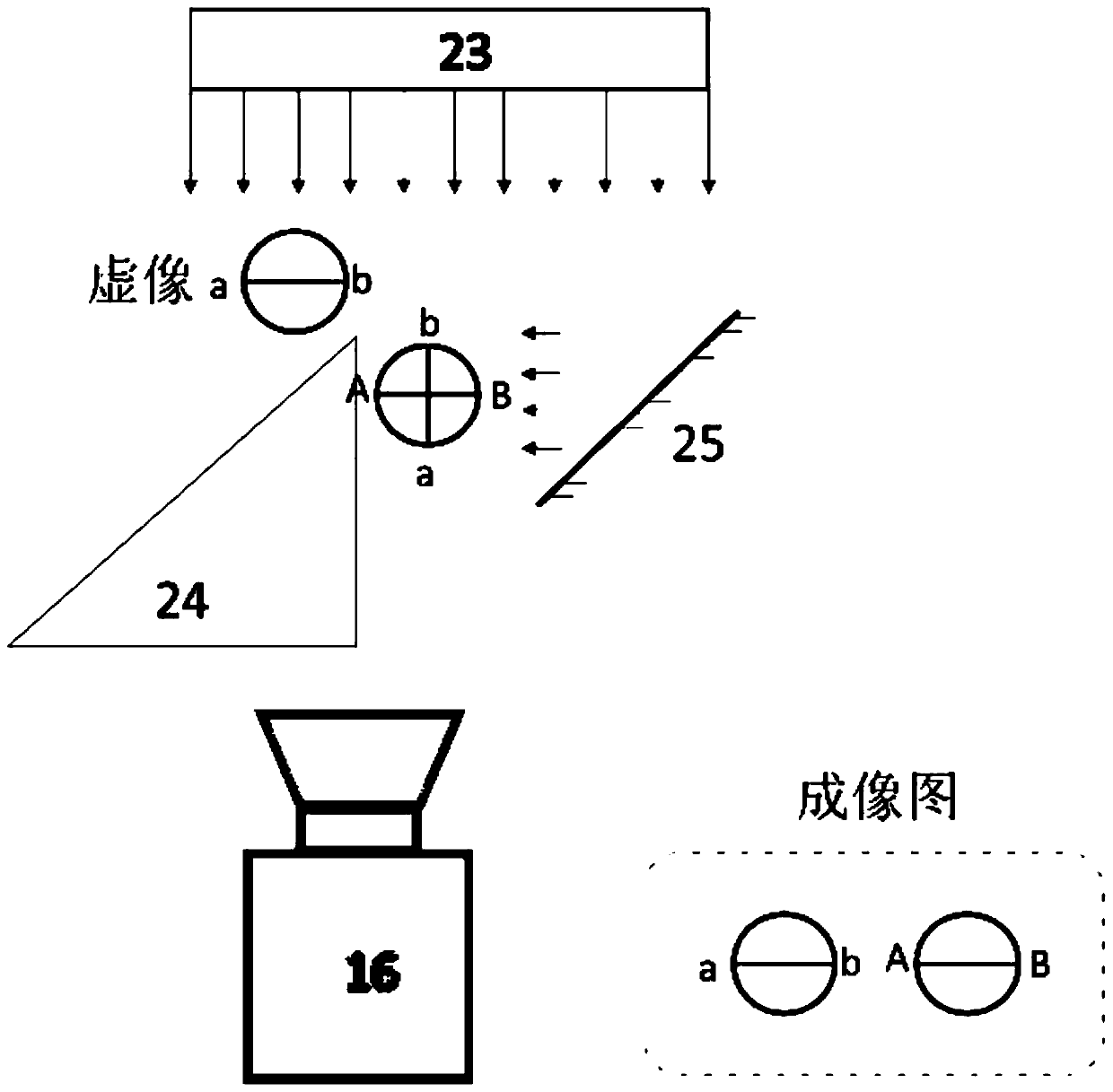

[0067] Step 1: Preset the data of the mass flow meter as two groups A and B; install the micro-channel, and debug the LED light source 11 and the camera 16;

[0068] Step 2: Open the valve of the safety venting device 19, the front and rear valves of the volumetric flowmeter 18, the front and rear valves of the microchannel, and the inlet valve of the mixing tank 7 to purge the nitrogen branch pipe valve; keep the volumetric flowmeter 18 bypass valve, microchannel bypass valve, The dosing system valve is closed;

[0069] Step 3: Open the purging nitrogen cylinder 5 valve to purge the pipeline;

[0070] Step 4: close the valve of the purge nitrogen cylinder 5 and the purge nitrogen branch pipe valve;

[0071] Step 5: o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com