A kind of powder active release agent, powder reclaimed rubber and production method thereof

A technology of release agent and reclaimed rubber, which is applied in the field of reclaimed rubber to achieve good activity, high compatibility and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

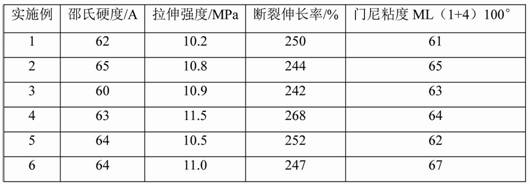

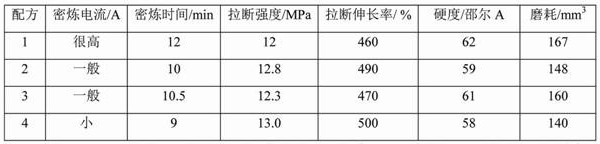

Examples

Embodiment 1

[0048] A kind of powder reclaimed rubber, its production method comprises the following steps:

[0049] (1) Preparation of powdery active release agent A: in parts by weight,

[0050] Silica wet product, calculated as dry product: 10

[0052] Tall Oil: 8

[0054] Pentachlorothiophenol zinc salt: 0.15

[0055] Sodium petroleum sulfonate: 0.3

[0056] ① Prepare sodium silicate into 10% aqueous solution a; ② Mix a with tall oil to form b; ③ Dissolve pentachlorothiophenol zinc salt and zinc stearate in petroleum sodium sulfonate to form c; ④ mix c Add dropwise to b to emulsify to form a water-soluble active release agent with a pH of 8-10 to obtain d; ⑤ mix d with the wet product of white carbon black for beating, pulverize to form e, and flash dry to obtain powdery active release agent A ;

[0057] (2) Add 10% of the waste rubber particles to the step (1) powdery active release agent A, and perform high-speed shear ...

Embodiment 2

[0077] A kind of powder reclaimed rubber, its production method comprises the following steps:

[0078] (1) Preparation of powdery active release agent A: in parts by weight,

[0079] Silica wet product, calculated as dry product: 10

[0080] Sodium silicate: 0.4

[0081] Tall Oil: 10

[0083] Pentachlorothiophenol zinc salt: 0.2

[0084] Sodium petroleum sulfonate: 0.1

[0085] ① Prepare sodium silicate into 10% aqueous solution a; ② Mix a with tall oil to form b; ③ Dissolve pentachlorothiophenol zinc salt and zinc stearate in petroleum sodium sulfonate to form c; ④ mix c Add dropwise to b to emulsify to form a water-soluble active release agent with a pH of 8-10 to obtain d; ⑤ mix d with the wet product of white carbon black for beating, pulverize to form e, and flash dry to obtain powdery active release agent A ;

[0086] (2) Add 15% of the waste rubber particles to the step (1) powdery active release agent, and perform high-speed shear ac...

Embodiment 3

[0106] A kind of powder reclaimed rubber, its production method comprises the following steps:

[0107] (1) Preparation of powdery active release agent A: in parts by weight,

[0108] Silica wet product, calculated as dry product: 12

[0109] Sodium silicate: 0.5

[0110] Tall Oil: 5

[0111] Zinc stearate: 0.3

[0112] Pentachlorothiophenol zinc salt: 0.1

[0113] Sodium petroleum sulfonate: 0.2

[0114] ① Prepare sodium silicate into 12% aqueous solution a; ② Mix a with tall oil to form b; ③ Dissolve pentachlorothiophenol zinc salt and zinc stearate in petroleum sodium sulfonate to form c; ④ mix c Add dropwise to b to emulsify to form a water-soluble active release agent with a pH of 8-10 to obtain d; ⑤ mix d with the wet product of white carbon black for beating, pulverize to form e, and flash dry to obtain powdery active release agent A ;

[0115] (2) Add 20% of waste rubber particles to step (1) powdery active release agent A, perform high-speed shear activation in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com