Foundry crude sand screening method

A screening method and raw sand technology, applied in casting molding equipment, manufacturing tools, cleaning/processing machinery of casting materials, etc., can solve problems such as low efficiency, insufficient drying efficiency, and inability to pass through sieve holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

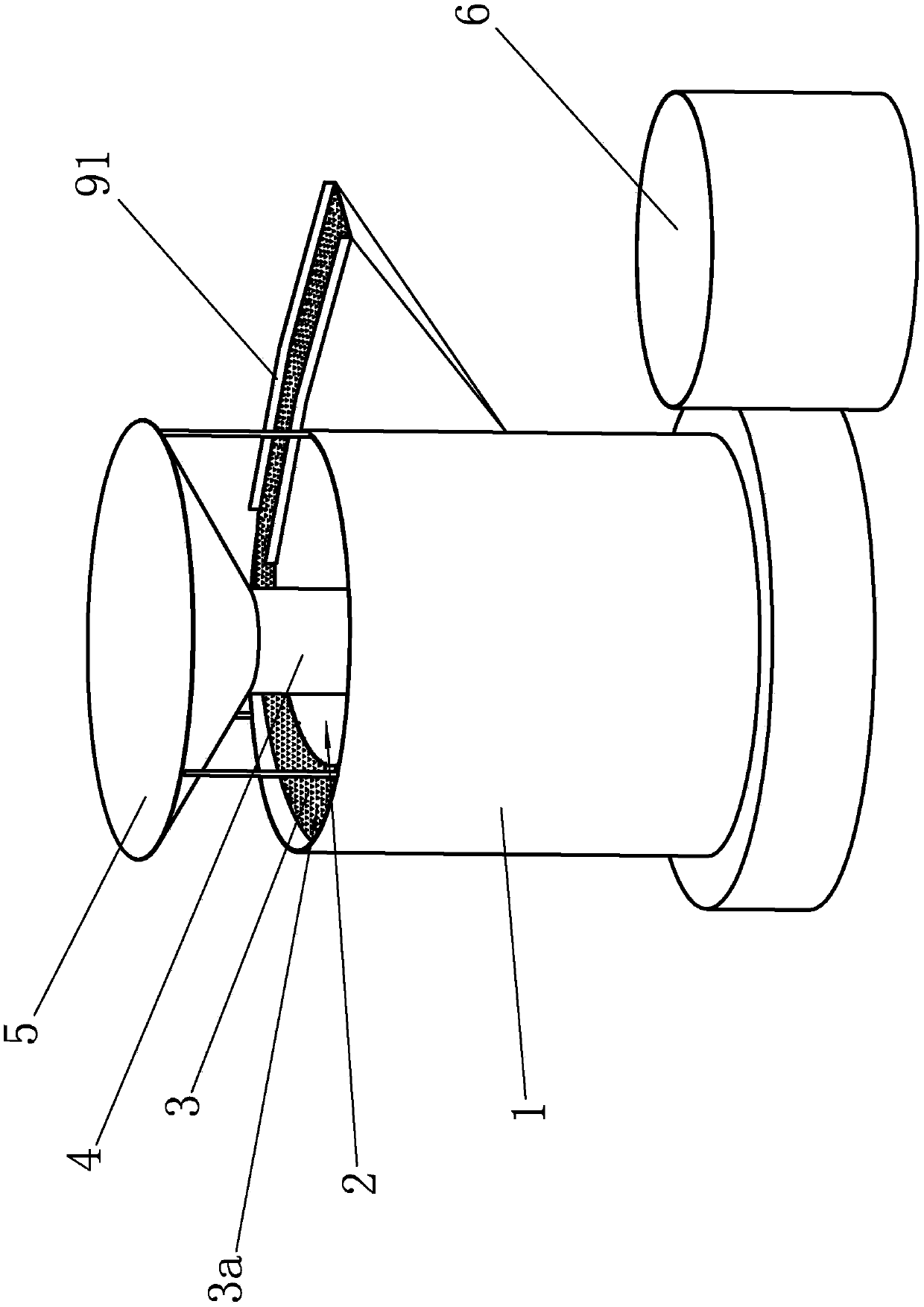

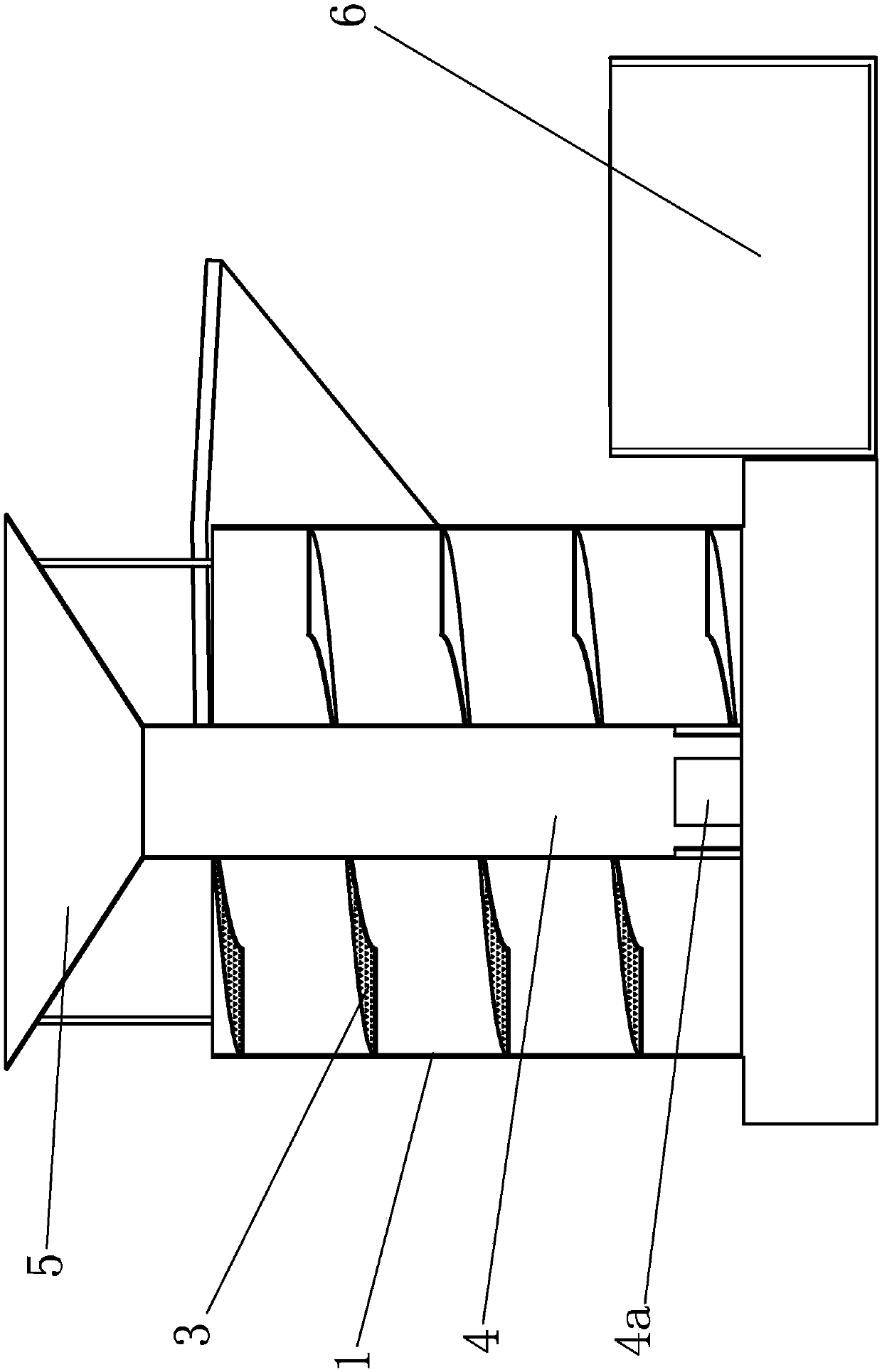

[0039] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0040] A method for screening raw foundry sand, characterized in that the method comprises the following steps: a, crushing sand treatment, using a sand crushing device to crush the agglomerated sand; b, removing impurities, using a sand filter device to crush the agglomerated sand a. Removal of impurities in the treated sand; c. Dust removal treatment, using a dust removal device to remove the dust mixed in the sand treated in step b; d, drying the sand treated in step c; e. d The treated sand is collected.

[0041] Such as figure 1 and figure 2 As shown, the sand crushing device in step a includes a first vibrating plate, the first vibrating plate includes a first disc body 1 with a top opening, the first disc body 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com