A method for safe regeneration and utilization of heavy metal contaminated soil after chemical leaching and remediation

A technology for chemical leaching and polluted soil, which is applied in the restoration of polluted soil, chemical instruments and methods, and other chemical processes, and can solve problems such as soil acidification and hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

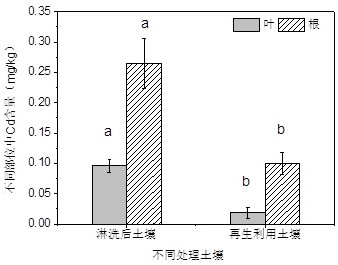

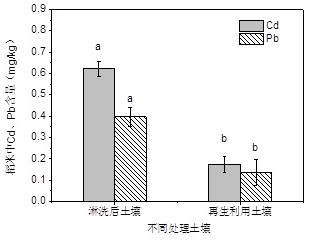

[0025] (1) The basic physical and chemical properties of the tested soil

[0026] The test soil was taken from the soil (0-20cm) of a Cd-contaminated farmland in Suxian District, Chenzhou City, Hunan Province, and the soil was naturally air-dried and passed through a 10-mesh sieve for later use. Accurately weigh 15kg of sieved soil into the rinsing container, add 0.05mol / L EDTA solution 150L with a solid-to-liquid ratio of 1:10, and strengthen the leaching under the action of ultrasonic waves (ultrasonic frequency is 25kHz, and the action time is 15min ). After the washing is completed, the washed farmland soil is obtained. The basic physical and chemical properties of the original contaminated soil and the soil after leaching are shown in Table 1.

[0027] Table 1 Basic physical and chemical properties of the tested soil

[0028]

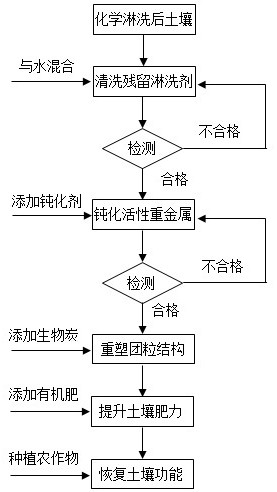

[0029] (2) Implementation methods and steps

[0030] ①Clean the residual eluent. After chemical leaching, 15kg of soil was added to 300L o...

Embodiment 2

[0044] (1) The basic physical and chemical properties of the tested soil

[0045] The test soil was taken from the plow layer soil (0-20cm) of a heavy metal polluted paddy field in Liuyang City, Hunan Province, and the soil was naturally air-dried and passed through a 10-mesh sieve for later use. Take 30kg of sieved soil into the rinsing container, add 0.05mol / L leaching agent nitrilotriacetic acid solution 300L at a solid-to-liquid ratio of 1:10, and rinse for 4 hours at a speed of 100r / min. After the washing is completed, the paddy field soil after washing is obtained. The basic physical and chemical properties of the original contaminated soil and the soil after leaching are shown in Table 4.

[0046] Table 4 Basic physical and chemical properties of the tested soil

[0047]

[0048] (2) Implementation methods and steps

[0049] ①Clean the residual eluent. After rinsing, the soil was 30kg, and the soil was added to 600L of water at a solid-to-liquid ratio of 1:20, st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com