Regrowth groove-filling GaN-based junction barrier Schottky diode structure and implementation method

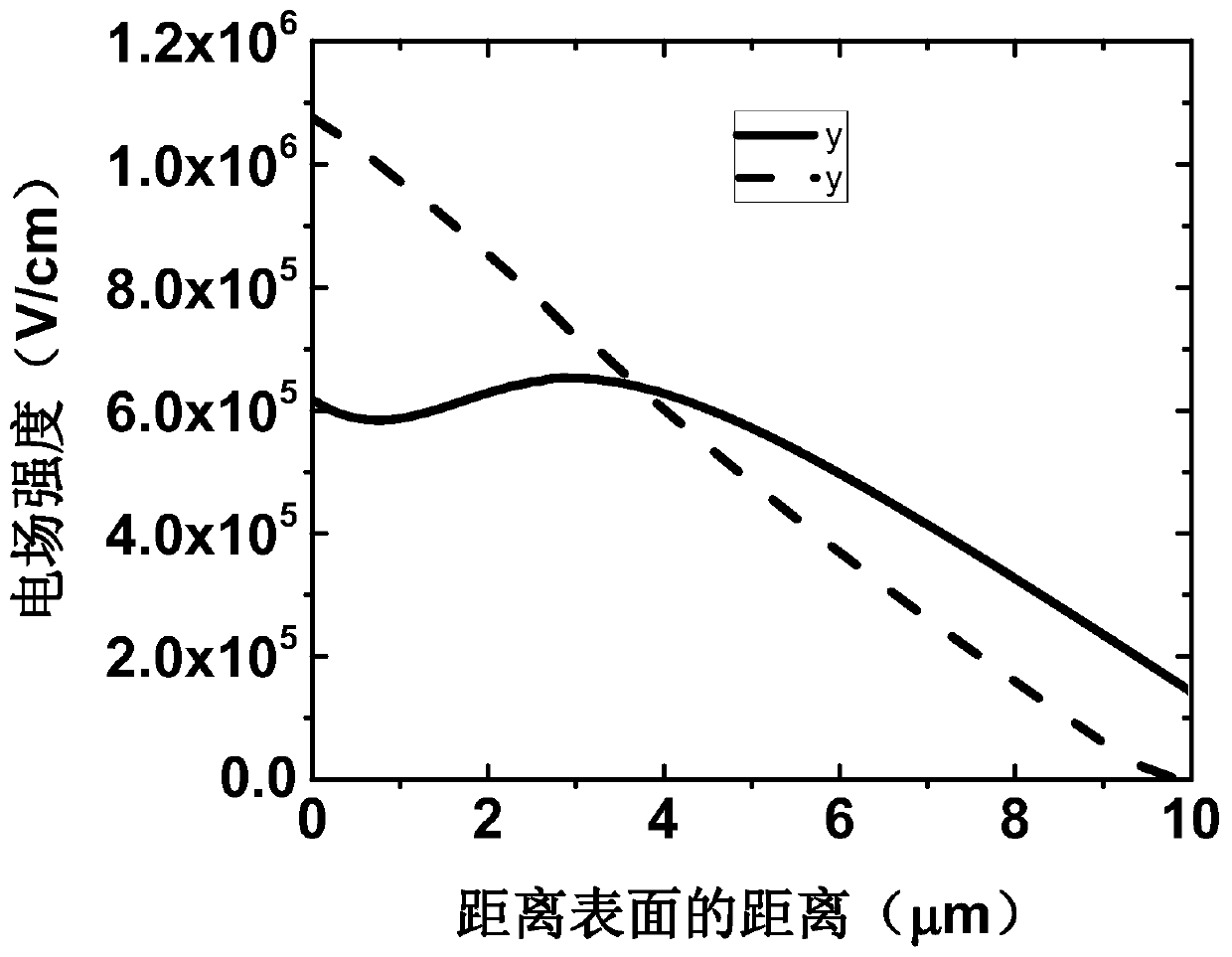

A technology of Schottky diode and realization method, applied in the field of microelectronics, can solve the problems of lack of GaN material modification, poor performance of GaN JBS, etc., and achieve the effects of suppressing electric field accumulation effect, improving breakdown electric field, and suppressing reverse leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In the following, the present invention will be described more fully with reference to the accompanying drawings, in which embodiments and their realization are shown, the described embodiment is only one form of realization in the present invention, that is, the present invention should not be interpreted are limited to the examples set forth herein. Based on the embodiment, the scope of the present invention is fully conveyed to those skilled in the art.

[0032] Hereinafter, exemplary embodiments of the present invention will be described in more detail with reference to the accompanying drawings.

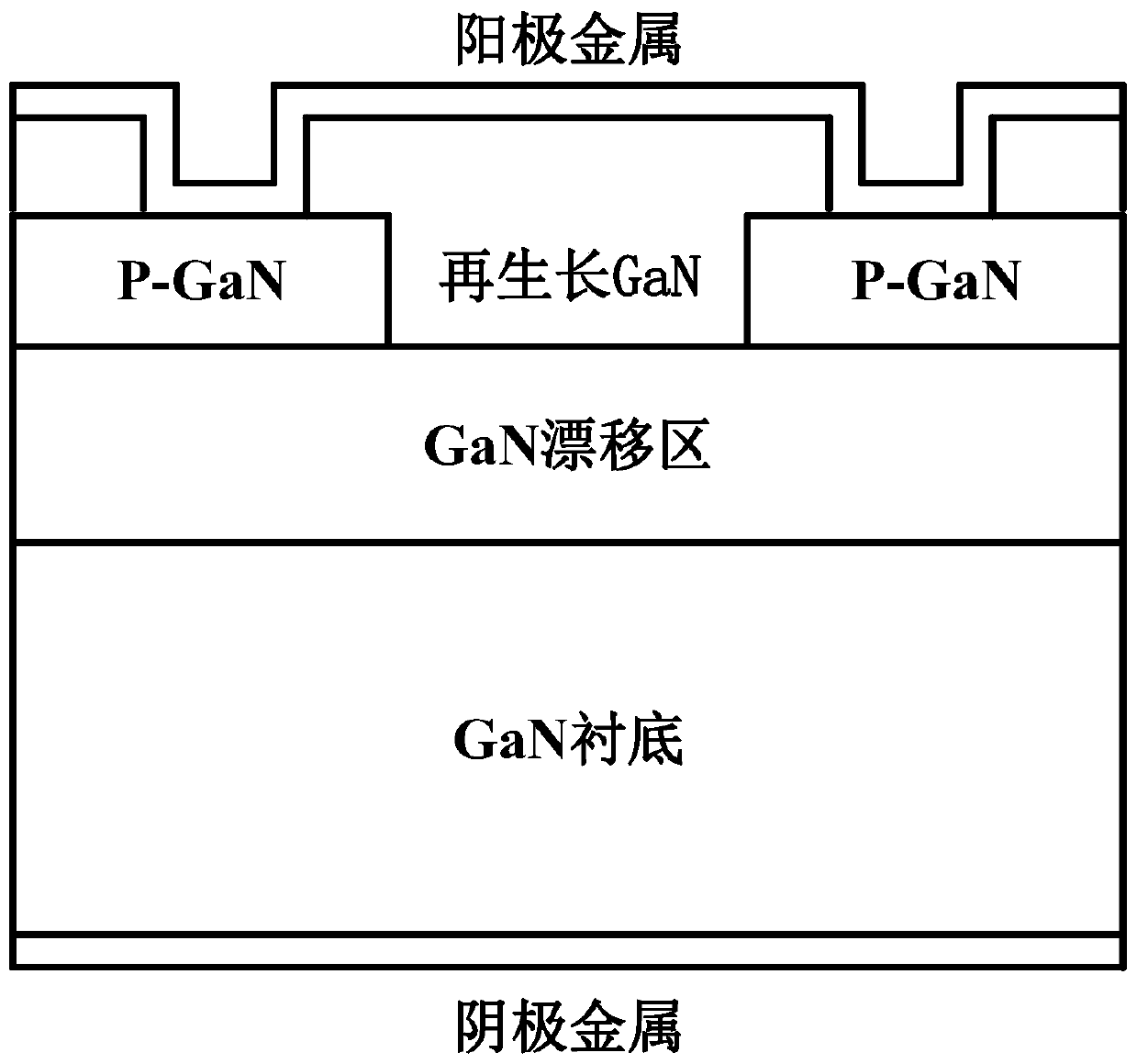

[0033] refer to figure 1 , the device structure from bottom to top includes cathode metal, substrate, n - -GaN drift region, P-type GaN, regrown n - -GaN and anode metal. Its preparation method comprises the following specific steps:

[0034] (1) if Figure 4 As shown, on a GaN free-standing substrate, a layer of n is first grown by MOCVD or MBE - -GaN drift region...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com