Ce-Co-S composite material as well as preparation method and application thereof

A composite material, ce-co-s technology, used in Ce-Co-S composite material and its preparation, the application field of super capacitor, can solve the problems of poor electrochemical stability, poor conductivity, hindering practical application, etc. Environmentally friendly, high energy density and power density, the effect of shortening synthesis time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of Ce-Co-S composite material, comprising the following steps:

[0029] 1mmol Co(NO 3 ) 2 ·6H 2 O, 1mmol Ce(NO 3 ) 3 ·6H 2 O, 6 mmol NH 4 F, 5mmol of urea was dissolved in 40mL of water, after magnetically stirring evenly, 0.3g of thioacetamide was added to it and quickly transferred to an 80mL polytetrafluoroethylene-lined stainless steel autoclave for one-step hydrothermal reaction. The hydrothermal reaction temperature was 180°C, the hydrothermal reaction time is 16h; the sample after hydroheating is taken out and cooled, then centrifuged, washed, and vacuum-dried at 60°C for 12h to obtain Ce-Co-S powder. After the active material is ground, it is evenly mixed with carbon black and polytetrafluoroethylene in a mass ratio of 8:1:1, pressed onto a nickel foam sheet (1cm×1cm), and dried in an oven at 60°C for 12h to obtain Ce-Co-S working electrode (note CCS-1).

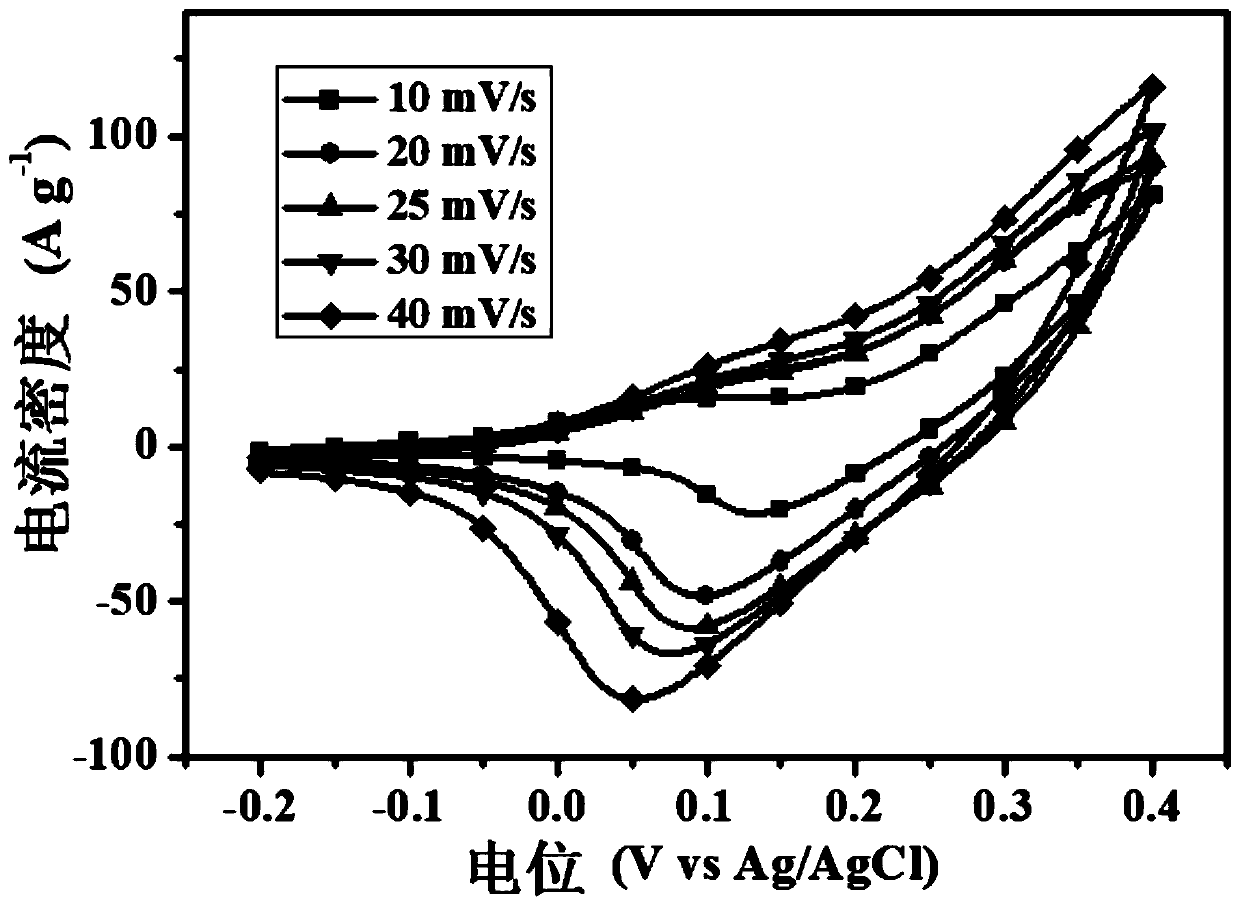

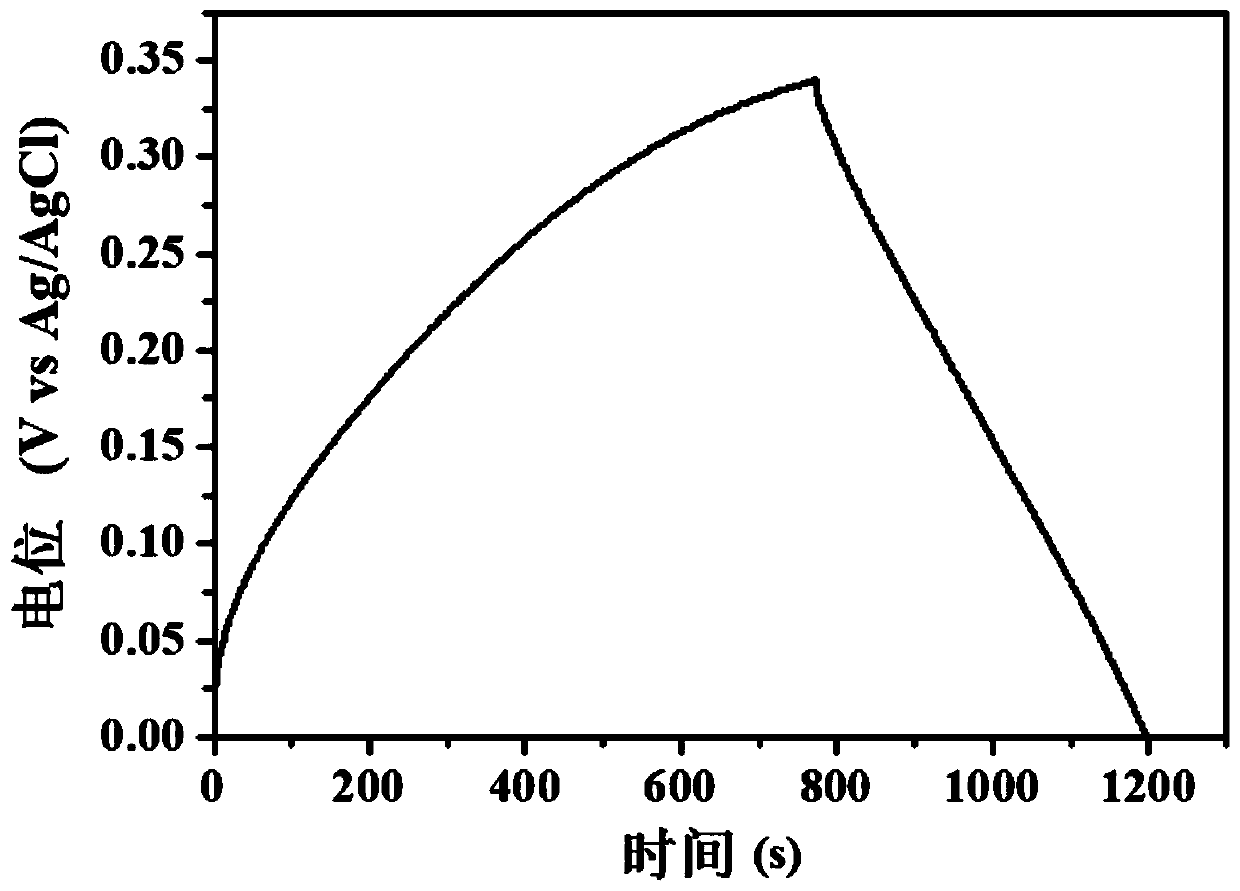

[0030] Jingchenhua CHI760e electrochemical workstation adopts cyclic voltammet...

Embodiment 2

[0034] A preparation method of Ce-Co-S composite material, comprising the following steps:

[0035] 1mmol Co(NO 3 ) 2 ·6H 2 O, 0.5mmol Ce(NO 3 ) 3 ·6H 2 O, 6 mmol NH 4 F, 5mmol of urea was dissolved in 40mL of water, after magnetically stirring evenly, 0.3g of thioacetamide was added to it and quickly transferred to an 80mL polytetrafluoroethylene-lined stainless steel autoclave for one-step hydrothermal reaction. The hydrothermal reaction temperature was 180°C, the hydrothermal reaction time is 16h; the sample after hydroheating is taken out and cooled, then centrifuged, washed, and vacuum-dried at 60°C for 12h to obtain Ce-Co-S powder. After the active material is ground, it is evenly mixed with carbon black and polytetrafluoroethylene in a mass ratio of 8:1:1, pressed onto a nickel foam sheet (1cm×1cm), and dried in an oven at 60°C for 12h to obtain Ce-Co-S working electrode (note CCS-2).

[0036] Jingchenhua CHI760e electrochemical workstation adopts cyclic voltammet...

Embodiment 3

[0038] A preparation method of Ce-Co-S composite material, comprising the following steps:

[0039] 1mmol Co(NO 3 ) 2 ·6H 2 O, 2mmol Ce(NO 3 ) 3 ·6H 2 O, 6 mmol NH 4 F, 5mmol of urea was dissolved in 40mL of water, after magnetically stirring evenly, 0.3 thioacetamide was added to it and quickly transferred to an 80mL polytetrafluoroethylene-lined stainless steel autoclave for one-step hydrothermal reaction, the hydrothermal reaction temperature was 180 °C, the hydrothermal reaction time is 16h; the hydrothermal sample is taken out to cool, then centrifuged, washed, and vacuum-dried at 60°C for 12h to obtain Ce-Co-S powder. After the active material is ground, it is evenly mixed with carbon black and polytetrafluoroethylene in a mass ratio of 8:1:1, pressed onto a nickel foam sheet (1cm×1cm), and dried in an oven at 60°C for 12h to obtain Ce-Co-S working electrode (note CCS-3).

[0040] Jingchenhua CHI760e electrochemical workstation adopts the method of cyclic voltamm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com