Cutting type spiral distribution sanitary heat exchanger

A heat exchanger, sanitary technology, applied in the field of shearing spiral split flow sanitary heat exchanger, can solve the problems of material cost waste, short service life, heat exchanger damage, etc., to achieve easy heat exchange and improve service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solution of the present invention will be described in further non-limiting detail below in combination with preferred embodiments and accompanying drawings.

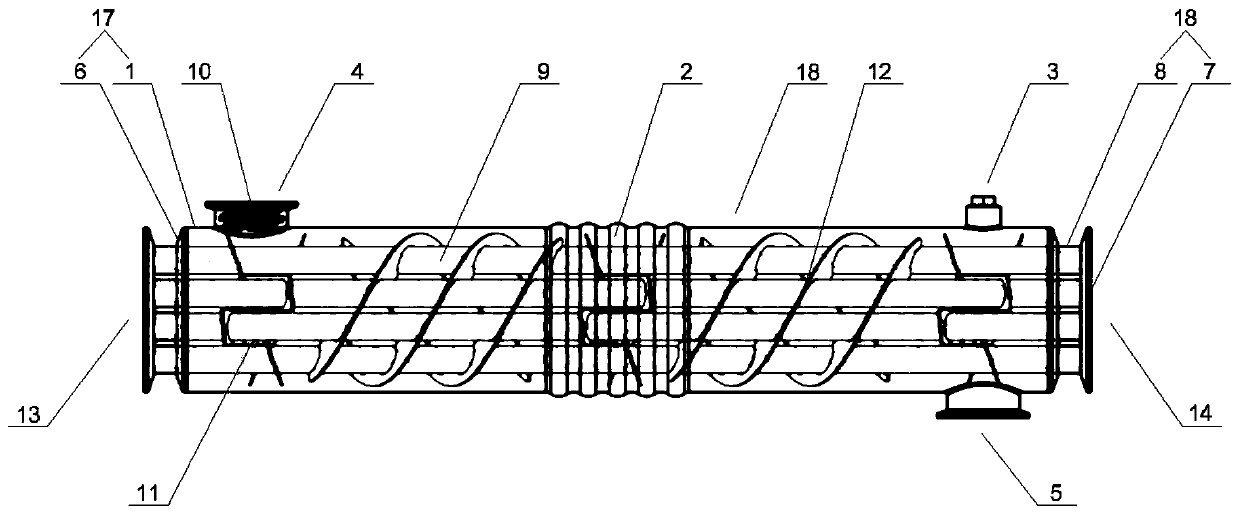

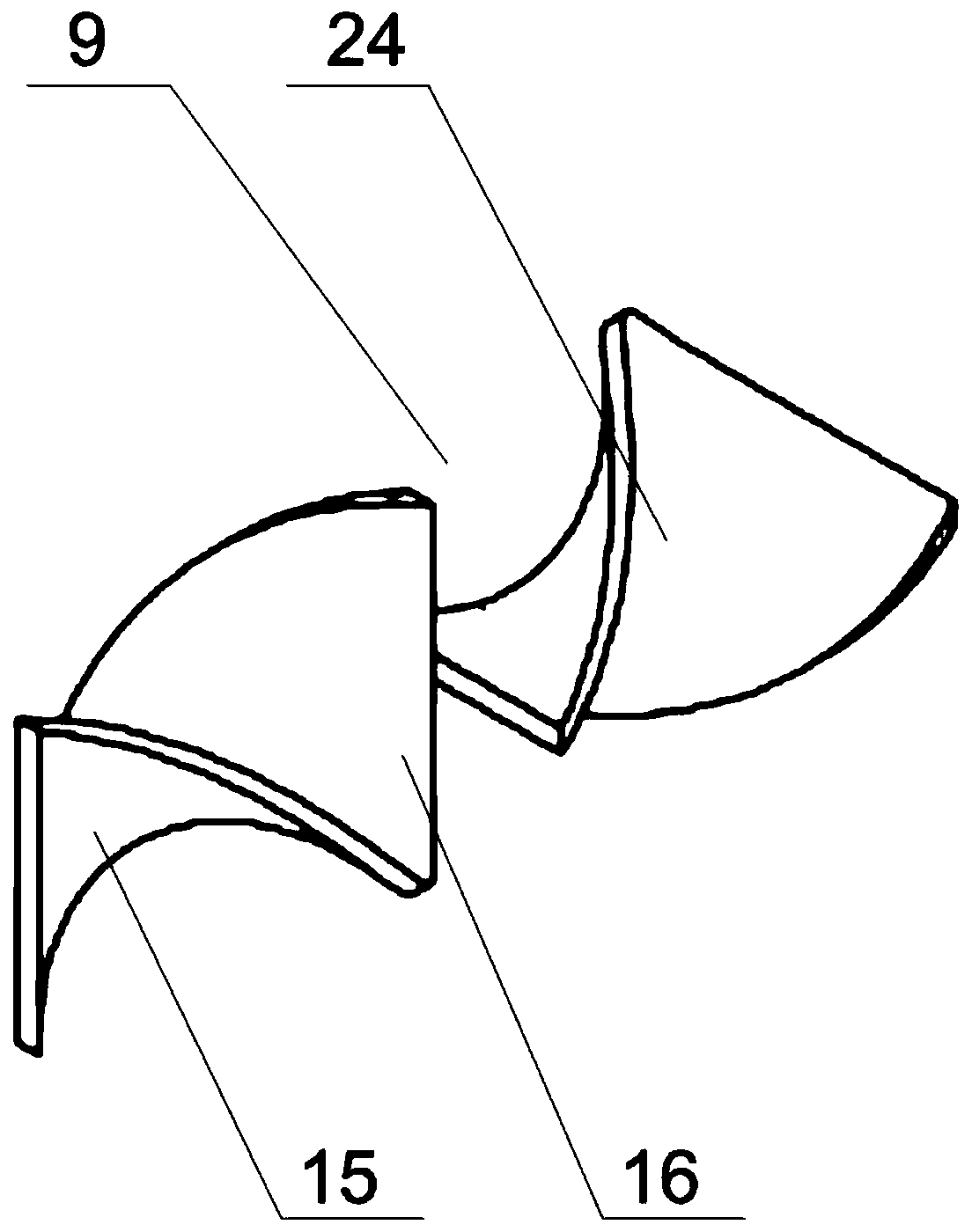

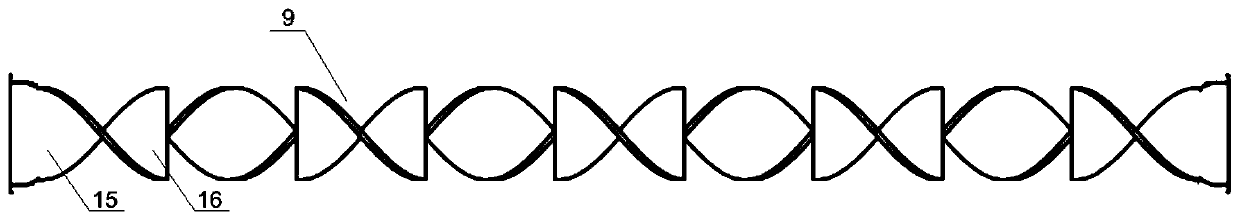

[0038] Such as figure 1 As shown, a shear-type spiral split-flow sanitary heat exchanger includes an outer tube pass 17 and an inner tube pass 18 arranged in the outer tube pass 17, corresponding to a preferred embodiment of the present invention, this heat exchanger is also called a heat exchanger. The heater is a device that transfers part of the heat of the hot fluid to the cold fluid. It is widely used in chemical, petroleum, food and many other industrial sectors. It plays an important role in production. It can be used for both heating medium and cooling medium .

[0039] The outer tube side 17 includes the shell 1 and the inner tube plate 6, the second spoiler 11 and the baffle plate 12 are set in the shell 1, the expansion joint 2 is set in the middle part of the shell 1, and the cooling / he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com