Method for recycling gold from gold-containing pregnant solution

A technology for recovering gold and precious liquid, applied in the field of gold recovery, can solve the problems of reducing the grade of gold mud, affecting the effect of zinc powder replacement, reducing the replacement recovery rate, etc., and achieve the effects of improving production quality, improving process production efficiency, and increasing replacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

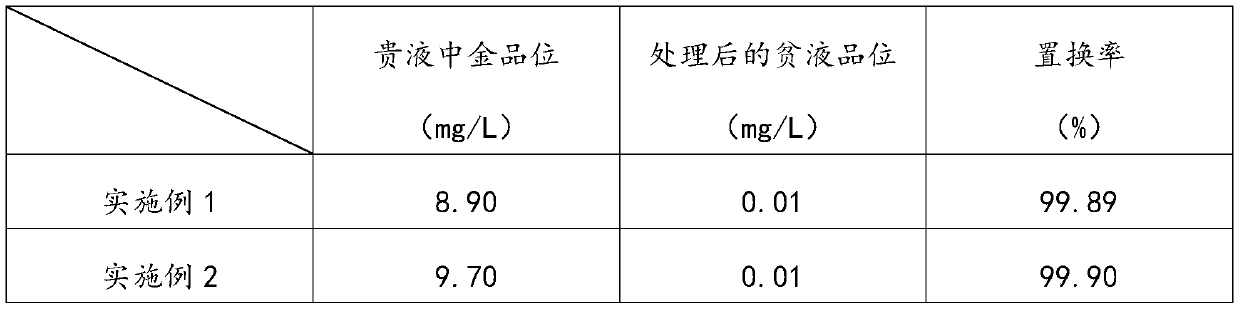

Examples

Embodiment 1

[0037] The present embodiment provides a kind of method that recovers gold from precious liquid containing gold, and it comprises the steps:

[0038] S1. Preparing precious liquid: said step S1 comprises the following steps:

[0039] S11. Grinding the gold-containing ore, and then performing press filtration and pulping to obtain a slurry with a pH value of 10;

[0040] S12. Add sodium cyanide to the sizing liquid obtained in step S11 for leaching reaction, and obtain leaching pulp, then perform dense washing and solid-liquid separation on the leaching pulp in sequence, and the obtained liquid is precious liquid, which is set aside.

[0041] S2. Purifying the precious liquid: at a temperature of 20°C, add the precious liquid prepared in step S1 into a filter press for impurity removal treatment to obtain purified precious liquid;

[0042] S3. Precious liquid deoxidation treatment: adding the precious liquid purified in step S2 into a deoxidation tower for deoxidation treatmen...

Embodiment 2

[0046] The present embodiment provides a kind of method that recovers gold from precious liquid containing gold, and it comprises the steps:

[0047] S1. Preparing precious liquid: said step S1 comprises the following steps:

[0048] S11. Grinding the gold-containing ore, and then performing press filtration and pulping to obtain a slurry with a pH value of 11;

[0049] S12. Add sodium cyanide to the sizing liquid obtained in step S11 for leaching reaction, and obtain leaching pulp, then perform dense washing and solid-liquid separation on the leaching pulp in sequence, and the obtained liquid is precious liquid, which is set aside.

[0050] S2. Purifying the precious liquid: at a temperature of 15°C, add the precious liquid prepared in step S1 into a filter press for impurity removal treatment to obtain purified precious liquid;

[0051] S3. Precious liquid deoxidation treatment: adding the precious liquid purified in step S2 into a deoxidation tower for deoxidation treatmen...

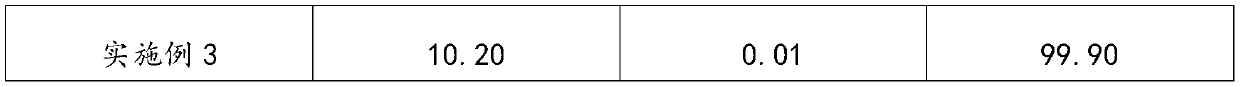

Embodiment 3

[0055] The present embodiment provides a kind of method that recovers gold from precious liquid containing gold, and it comprises the steps:

[0056] S1. Preparing precious liquid: said step S1 comprises the following steps:

[0057] S11. Grinding the gold-containing ore, and then performing pressure filtration and pulping to obtain a slurry with a pH value of 12;

[0058] S12. Add calcium cyanide to the sizing liquid obtained in step S11 for leaching reaction, and obtain leaching pulp, then perform dense washing and solid-liquid separation on the leaching pulp in sequence, and the obtained liquid is noble liquid, which is set aside.

[0059] S2. Purifying the precious liquid: at a temperature of 25°C, adding the precious liquid prepared in step S1 into a filter press for impurity removal treatment to obtain purified precious liquid;

[0060] S3. Precious liquid deoxidation treatment: adding the precious liquid purified in step S2 into a deoxidation tower for deoxidation trea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com