Crosslinked anion exchange membrane based on polyphenyl ether/polyvinyl alcohol and preparation method

An anion-exchange membrane and polyvinyl alcohol technology, applied in electrochemical generators, fuel cells, electrical components, etc., can solve the problems of low membrane ion conductivity and severe swelling, so as to improve ion conductivity, reduce swelling, The effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Take a certain amount of polyphenylene ether in a three-necked flask, add an appropriate amount of chlorobenzene, and slowly raise the temperature to 80°C under the protection of nitrogen. After the polyphenylene ether is completely dissolved, add 40% wt of N-bromosuccinimide and 2 , 2'-azobisisobutyronitrile (the amount used is 0.5% of the mass of polyphenylene ether), stirred evenly and heated under reflux for 3 hours. After cooling, the reaction mixture was transferred to a beaker and washed several times with ethanol. The polymer was collected and dried under vacuum to obtain bromomethylated polyphenylene oxide (BPPO).

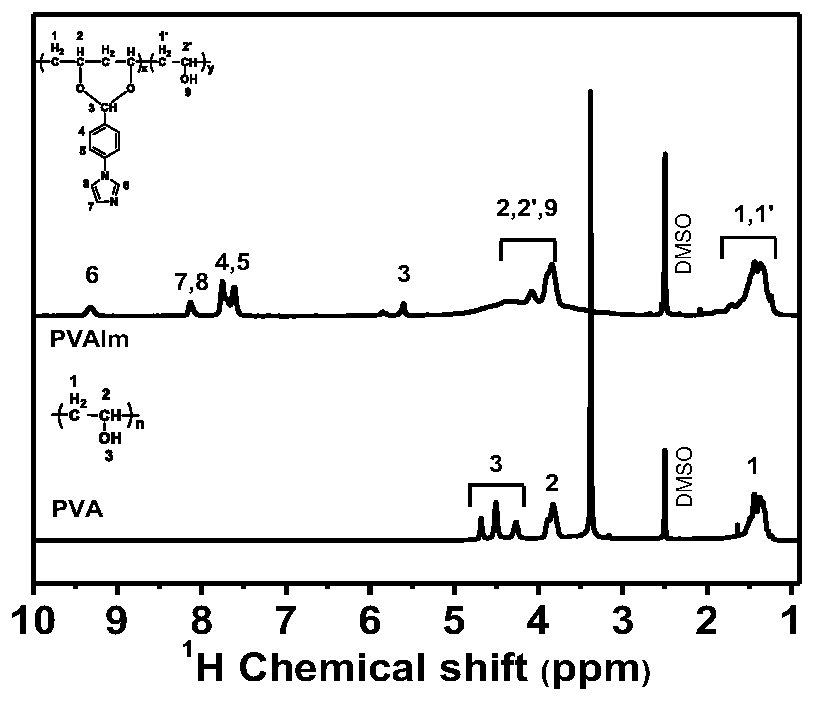

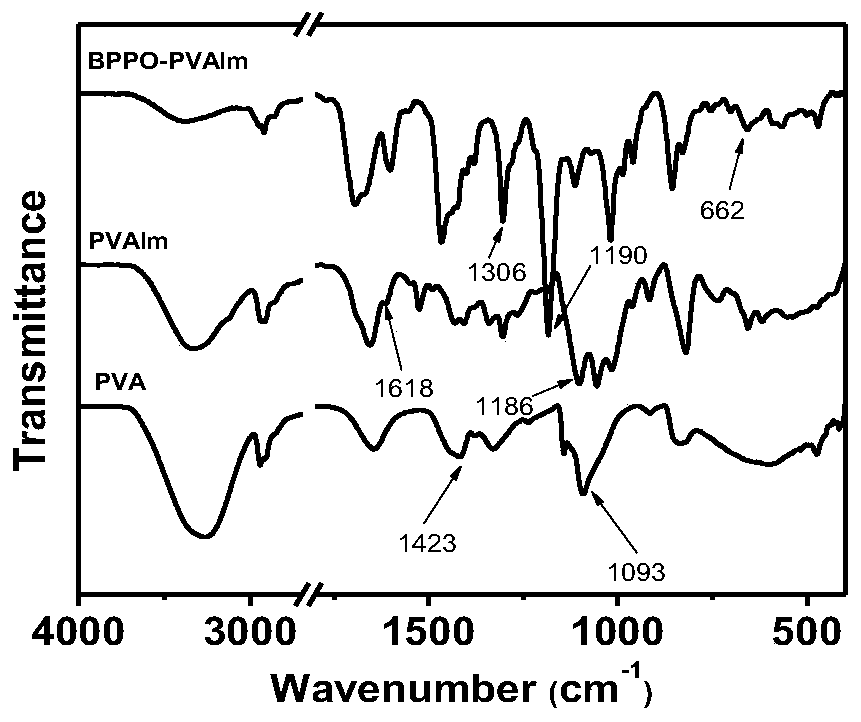

[0033] Get a certain amount of polyvinyl alcohol (PVA) and dissolve in dimethyl sulfoxide (DMSO), then add 10%wt p-imidazole benzaldehyde and concentrated hydrochloric acid (consumption is 0.5% of polyvinyl alcohol quality). After stirring at 50° C. for 72 hours, the resulting mixture was poured into deionized water containing sodium hydroxide to p...

Embodiment 2

[0043] Take a certain amount of polyphenylene ether in a three-necked flask, add an appropriate amount of chlorobenzene, and slowly raise the temperature to 60°C under the protection of nitrogen. After the polyphenylene ether is completely dissolved, add 40% wt of N-bromosuccinimide and 2 , 2'-azobisisobutyronitrile (the amount used is 0.6% of the mass of polyphenylene ether), stirred evenly and heated under reflux for 4 hours. After cooling, the reaction mixture was transferred to a beaker and washed several times with ethanol. The polymer was collected and dried under vacuum to obtain bromomethylated polyphenylene oxide (BPPO).

[0044] Get a certain amount of polyvinyl alcohol (PVA) and dissolve in dimethyl sulfoxide (DMSO), then add 10%wt p-imidazole benzaldehyde and concentrated hydrochloric acid (consumption is 0.5% of polyvinyl alcohol quality). After stirring at 60° C. for 72 hours, the resulting mixture was poured into deionized water containing sodium hydroxide to p...

Embodiment 3

[0048] Take a certain amount of polyphenylene ether in a three-necked flask, add an appropriate amount of chlorobenzene, and slowly raise the temperature to 50°C under the protection of nitrogen. After the polyphenylene ether is completely dissolved, add 40% wt of N-bromosuccinimide and 2 , 2'-azobisisobutyronitrile (the amount used is 1.0% of the mass of polyphenylene ether), stirred evenly and heated under reflux for 5 hours. After cooling, the reaction mixture was transferred to a beaker and washed several times with methanol. The polymer was collected and dried under vacuum to obtain bromomethylated polyphenylene oxide (BPPO).

[0049] Get a certain amount of polyvinyl alcohol (PVA) and dissolve in dimethyl sulfoxide (DMSO), then add 10%wt p-imidazole benzaldehyde and concentrated hydrochloric acid (consumption is 0.5% of polyvinyl alcohol quality). After stirring at 50° C. for 60 hours, the resulting mixture was poured into deionized water containing sodium hydroxide to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com