Optimized manufacturing method of paraffin sections of different flower tissues of phalaenopsis amabilis

A production method and a technology of paraffin sectioning, which are applied in the preparation, sampling, and measuring devices of test samples, can solve the problems of less observation of pedicels and petals, and achieve short production methods, save time, and maintain integrity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

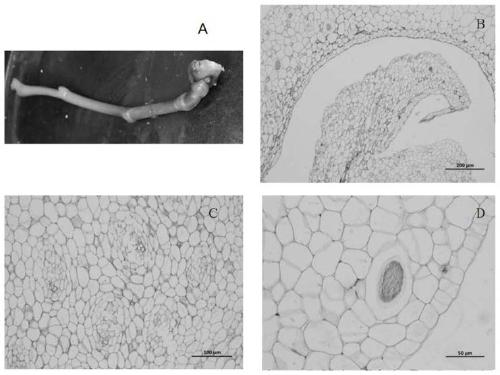

[0046] The making of embodiment 1 Phalaenopsis petal tissue paraffin section

[0047] 1. Fixing: Wash the Phalaenopsis petals, take fresh tissues and fix them in FAA fixative solution containing 50% alcohol. Aspirate the fixative until no more air bubbles are produced to remove intercellular air from the material. After the fixation time is more than 24 hours, take the tissue out of the fixative solution and use a scalpel in the fume hood to smooth the tissue at the target site, thin the tissue to 2-3mm, and put the trimmed tissue into the dehydration box.

[0048] 2. Dehydration: Put the dehydration box into the hanging basket and dehydrate with gradient alcohol in the dehydrator. The alcohol gradient and dehydration time are as follows: 75% alcohol for 4 hours-85% alcohol for 2 hours-90% alcohol for 2 hours-95% Alcohol for 1 hour-absolute ethanol for 30 minutes-absolute ethanol for 30 minutes-alcohol benzene for 5 minutes-xylene for 5 minutes-xylene for 5 minutes.

[0049]...

Embodiment 2

[0055] The making of embodiment 2 Phalaenopsis non-lignified pedicel tissue paraffin section

[0056] 1. Fixing: Clean the non-lignified pedicel (young pedicel) of Phalaenopsis, take fresh tissue and fix it in standard fixative solution (FAA fixative solution) containing 70% alcohol. Aspirate the fixative until no more air bubbles are produced to remove intercellular air from the material. After the fixation time is more than 24 hours, take the tissue out of the fixative and use a scalpel in the fume hood to smooth the tissue at the target site, thin the tissue to 2-3 mm, and put the trimmed tissue into the dehydration tray.

[0057] 2. Softening: Submerge the embedding frame with ethylenediamine softener, seal it, and put it in a blast drying oven at 55°C for softening. The softener replacement cycle is 7 days, and the softening degree is observed once a week, and the softening time is about 14 days.

[0058] 3. Dehydration: Put the dehydration box into the hanging basket a...

Embodiment 3

[0060] The making of embodiment 3 Phalaenopsis lignified pedicel tissue paraffin section

[0061] Referring to Example 2, wherein the softening time of step 2 is about 30 days.

[0062] Phalaenopsis lignified pedicel tissue sections stained blue-green ( image 3 ), which can be clearly distinguished from petal tissue and unlignified pedicel tissue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com