A connection structure, connection method and application of a quartz tuning fork and a base

A technology of quartz tuning fork and connection structure, which is applied in the direction of gyro effect for speed measurement, gyroscope/steering induction equipment, instruments, etc., can solve problems such as thermal stress, gas release, thermal expansion coefficient mismatch, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

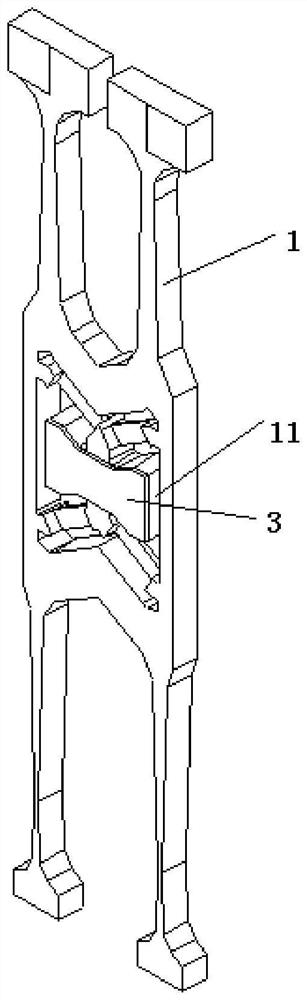

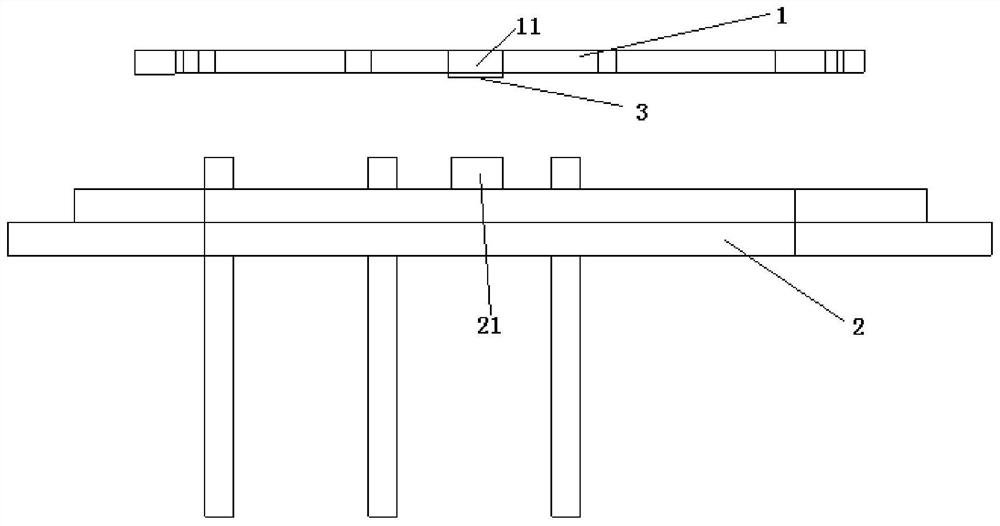

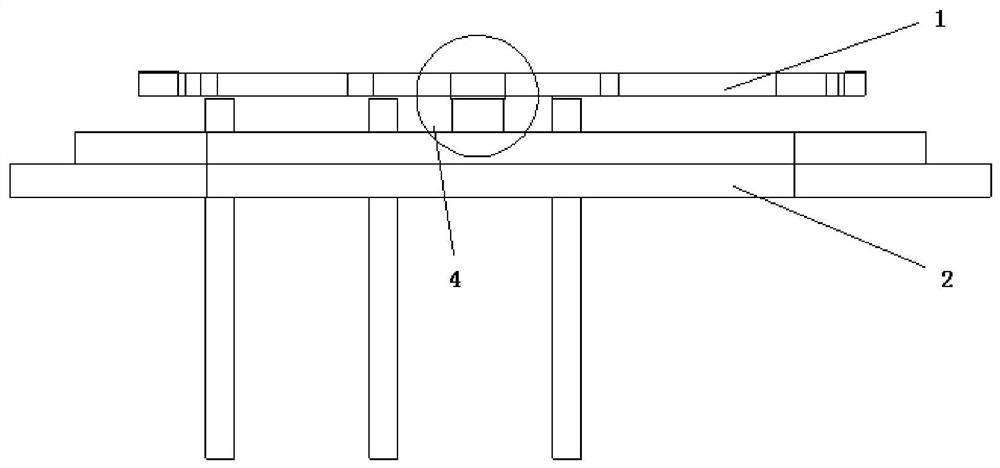

[0056] This embodiment provides a method for connecting a quartz tuning fork to a base, such as Figure 1-Figure 6 As shown, it specifically includes the following steps:

[0057] (1) On the central island 11 of the quartz tuning fork 1, magnetron sputtering is used to sequentially deposit a 20nm Cr layer 31 and a 6000nm first Au layer 32;

[0058] (2) The structure obtained in step (1) is precisely defined by using a photolithography process, so that the area corresponding to the target structure is covered by photoresist;

[0059] (3) A wet etching process is adopted for the Cr layer 31 and the first Au layer 32, and after the etching is completed, the photoresist is removed to form a target pattern;

[0060] (4) Precisely define the structure obtained in step (3) by photolithography, so that the region corresponding to the target structure is not covered by photoresist;

[0061] (5) adopt thermal evaporation to deposit the second Au layer 34 of the Sn layer 33 of 4000nm a...

Embodiment 2

[0073] This embodiment provides a method for connecting a quartz tuning fork to a base, such as Figure 1-Figure 6 As shown, it specifically includes the following steps:

[0074] (1) On the central island 11 of the quartz tuning fork 1, magnetron sputtering is used to sequentially deposit a 19nm Cr layer 31 and a 6300nm first Au layer 32;

[0075] (2) The structure obtained in step (1) is precisely defined by using a photolithography process, so that the area corresponding to the target structure is covered by photoresist;

[0076] (3) A wet etching process is adopted for the Cr layer 31 and the first Au layer 32, and after the etching is completed, the photoresist is removed to form a target pattern;

[0077] (4) Precisely define the structure obtained in step (3) by photolithography, so that the region corresponding to the target structure is not covered by photoresist;

[0078] (5) adopt thermal evaporation to deposit the second Au layer 34 of the Sn layer 33 of 4200nm a...

Embodiment 3

[0090] This embodiment provides a method for connecting a quartz tuning fork to a base, such as Figure 1-Figure 6 As shown, it specifically includes the following steps:

[0091] (1) On the central island 11 of the quartz tuning fork 1, magnetron sputtering is used to sequentially deposit a Cr layer 31 of 21 nm and a first Au layer 32 of 5700 nm;

[0092] (2) The structure obtained in step (1) is precisely defined by using a photolithography process, so that the area corresponding to the target structure is covered by photoresist;

[0093] (3) A wet etching process is adopted for the Cr layer 31 and the first Au layer 32, and after the etching is completed, the photoresist is removed to form a target pattern;

[0094] (4) Precisely define the structure obtained in step (3) by photolithography, so that the region corresponding to the target structure is not covered by photoresist;

[0095] (5) adopt the second Au layer 34 of the Sn layer 33 of thermal evaporation deposition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com