Plastic stop valve

A cut-off valve, plastic technology, applied in the direction of valve lift, valve details, valve device, etc., can solve the problems of inability to replace the valve stem, water leakage, etc., reduce the use of metal materials, ensure normal service life, and facilitate maintenance and replacement operations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

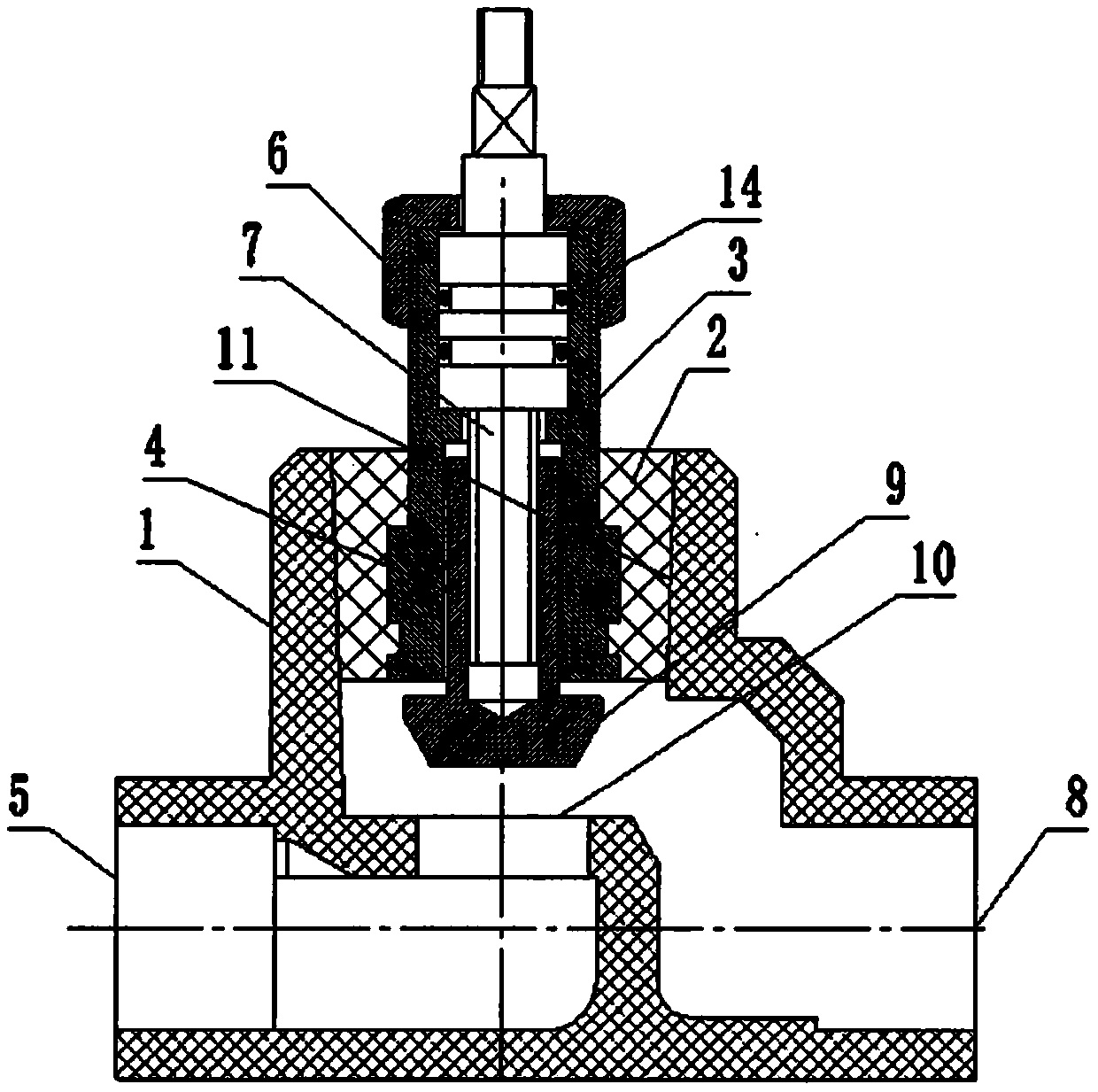

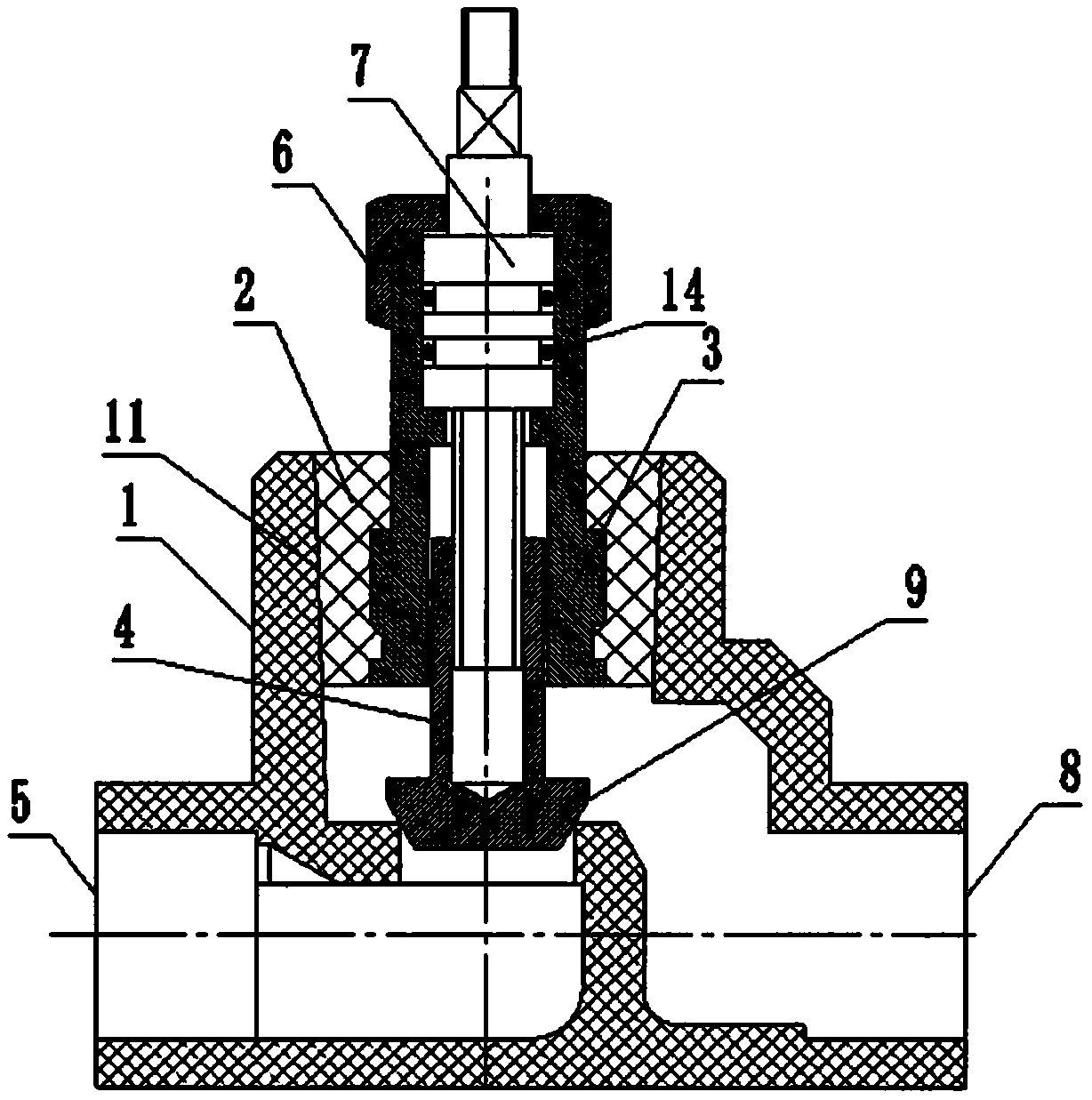

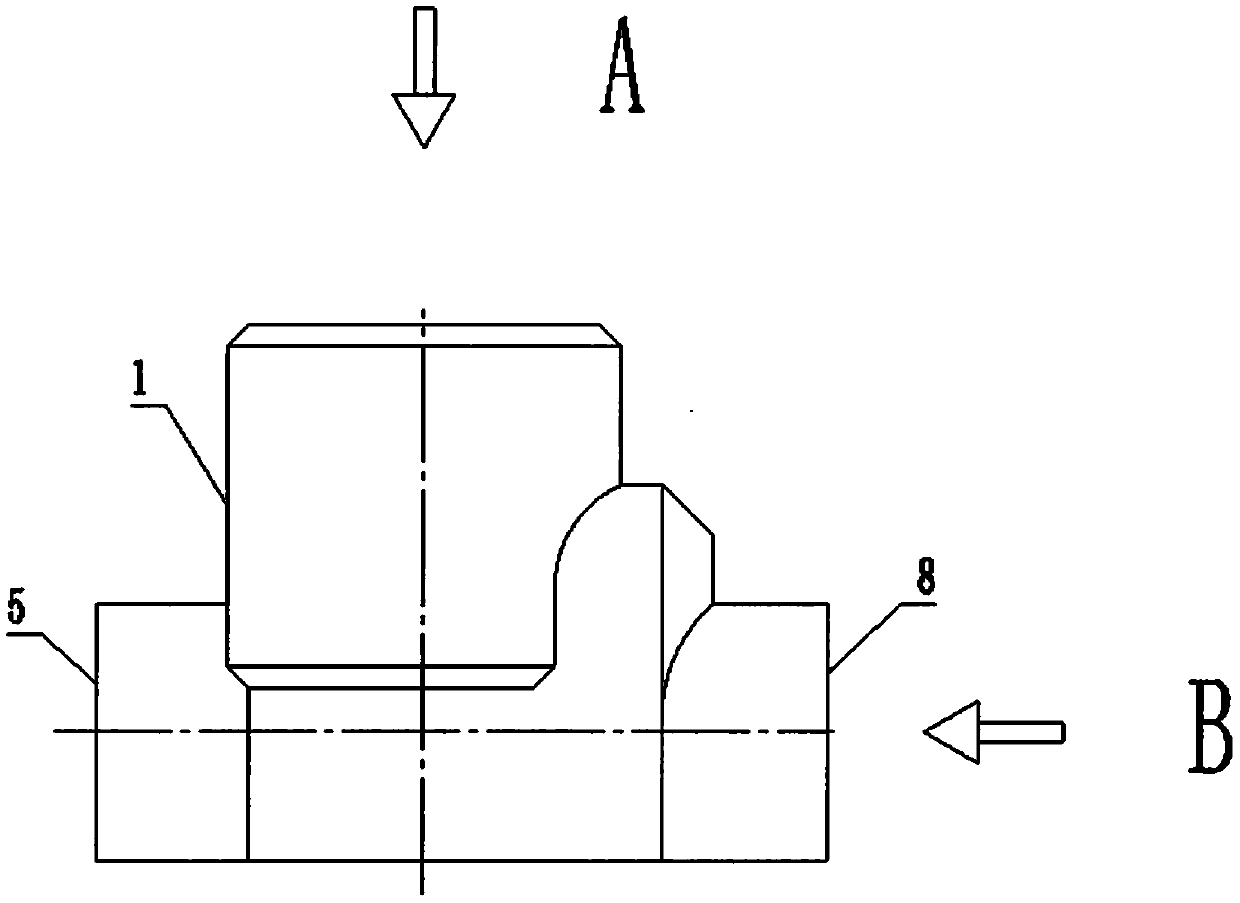

[0072] Such as Figure 1-23 As shown, the structure of the plastic globe valve in this example includes a bonnet connection insert cap 6, a valve disc 9, a valve stem 7 with an extended operating end, and a plastic valve body 1, and a valve seat is arranged in the plastic valve body 1. The valve seat has a valve seat opening 10, and the two ends of the plastic valve body 1 respectively have an inlet port 5 and an outlet port 8 communicating with the valve seat opening 10, and the inlet port 5 and the outlet port 8 are hot-melt Socket-type interface, the disc 9 has a disc rod 4, the disc rod 4 is located in the through hole of the valve cover connecting insert 3, the external thread of the valve rod 7 cooperates with the internal thread of the disc rod 4 and constitutes a kinematic pair The rotation of the valve rod 7 drives the valve disc rod 4, which is restricted to rotate, to lift the valve disc 9 and cooperate with the valve seat opening 10 to form a switch. The through ho...

Embodiment 2

[0074] Such as Figures 24 to 29 shown. The basic structure of the plastic globe valve in this example is similar to that of Embodiment 1, the difference is that the upper part of the valve stem 7 of the plastic globe valve in this embodiment is fixed with a hand wheel 18, and the outer wall of the valve cover connecting insert 3 is sleeved with The bonnet connecting insert sealing cover 12, the external thread of the bonnet connecting insert 3 is matched with the internal thread of the bonnet connecting insert sealing cover 12 through the outer wall, and the bonnet connecting insert sealing cover 12 is matched with the internal thread of the bonnet connecting insert sealing cover 12. A bonnet connection insert O-ring 13 is provided between the plastic connection transition piece 2 and the outer wall of the bonnet connection insert 3 .

Embodiment 3

[0076] Such as Figures 30-38 shown. The basic structure of the plastic globe valve in this example is similar to that of Embodiment 2, the difference is that there is an anti-loose gasket 15 between the bonnet connection insert cap 6 and the bonnet connection insert 3, and the anti-loose gasket 15 has two anti-rotation extensions 16 , and the valve cover connecting insert 3 has an anti-rotation groove 17 cooperating with the anti-rotation extensions 16 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com