Structural chromogenic textile with asymmetric wetting characteristics as well as preparation method and application thereof

A technology with structural color-generating and wetting characteristics, applied in textiles, papermaking, dyeing, etc., can solve the problems of complex processing, numerous operating procedures, and energy consumption, and achieve bright colors, strong universality, and simple procedures. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

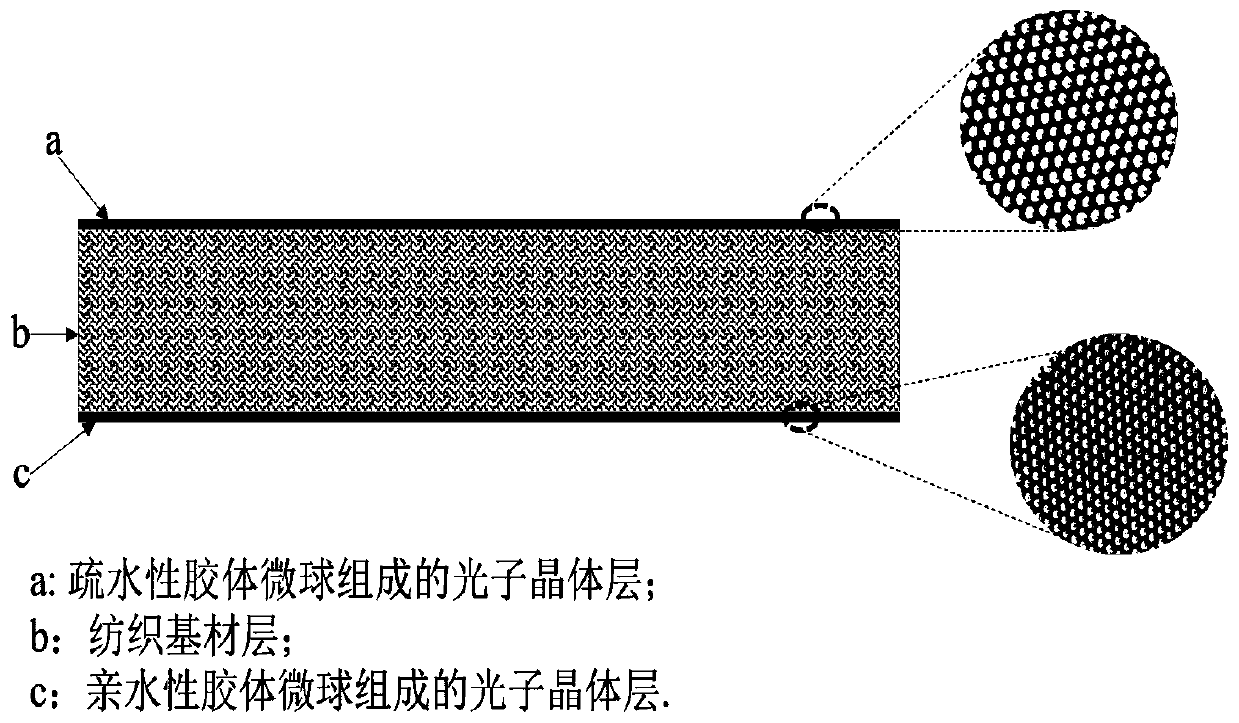

[0049] Further, the present application provides a method for preparing the above-mentioned structural color-producing textiles with asymmetric wetting properties, the following steps:

[0050] 1) Configure the structural chromogenic ink I including hydrophobic colloidal microspheres and the structural chromogenic ink II including hydrophilic colloidal microspheres;

[0051] 2) Coating the structural color-forming ink I on the first surface of the textile substrate and curing it to obtain a textile substrate having a hydrophobic photonic crystal layer on the first surface;

[0052] 3) The second surface of the textile substrate treated in step 2) is coated with the structural color-generating ink II and cured to obtain the structural color-generating textile with asymmetric wetting properties.

[0053] It can be understood that the first surface of the textile substrate can also be coated with the structural color-forming ink II and solidified to obtain a textile substrate wit...

Embodiment 1

[0070] This embodiment provides a method for preparing a structurally colored polyester fabric with asymmetric wetting properties, and the specific steps are as follows:

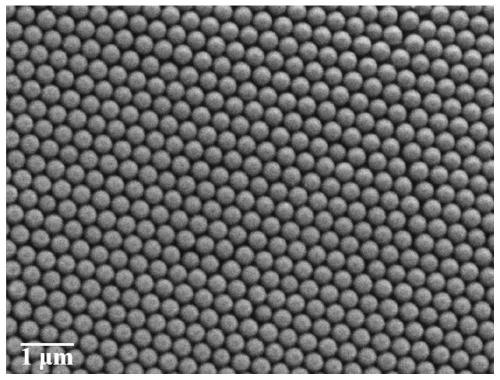

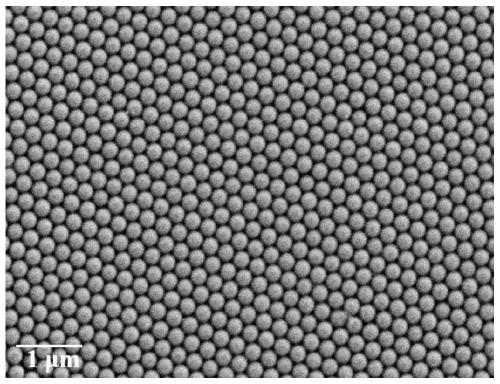

[0071] (1) Preparation of structural chromogenic ink: the main body is the dispersion of hydrophobic polystyrene colloidal microspheres (particle size is 320nm, monodispersity index is 0.08) with a solid content of 20%, diluted 10 times with deionized water Finally, compound 0.5% of sodium carbonate, 0.5% of polyethylene glycol, 1.0% of urea and 2.0% of N,N-dimethylacetamide, which account for the mass of the whole solution, and mix well to obtain the structural color-forming ink I; With the dispersion liquid of hydrophilic silica colloidal microspheres (particle size: 220nm, monodispersity index: 0.03) with a solid content of 20% as the main body, after diluting 10 times with deionized water, the compound accounts for 0.5% of the overall solution mass. % citric acid, 0.5% polyethylene glycol, 1.0% glycerin ...

Embodiment 2

[0076]This embodiment provides a method for preparing a structurally colored cotton fabric with asymmetric wetting properties, and the specific steps are as follows:

[0077] (1) Preparation of structural chromogenic ink: the dispersion liquid of hydrophobic polystyrene colloidal microspheres (particle size is 240nm, monodispersity index is 0.06) with a solid content of 25% is the main body, diluted 10 times with deionized water Finally, compound 0.5% of sodium carbonate, 1% of polyethylene glycol, 1.0% of glycerin and 2.0% of N,N-dimethylacetamide in the mass of the whole solution, and mix well to obtain the structural color-forming ink I; The dispersion of hydrophilic silica colloidal microspheres (particle size: 180nm, monodispersity index: 0.03) with a solid content of 20% as the main body, after being diluted 10 times with deionized water, the compound accounts for 1% of the overall solution mass. % citric acid, 0.5% polyethylene glycol, 1.0% urea and 2.0% N,N-dimethylace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com