Parasitic patch array antenna substrate integrated waveguide feed

A waveguide feeding and parasitic patch technology, applied in the direction of electrical short antennas, antennas, resonant antennas, etc., can solve the problems of multi-surface wave loss of radiating patches, narrow antenna bandwidth, and high quality factor, to expand bandwidth and increase bandwidth. , Improve the effect of antenna gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

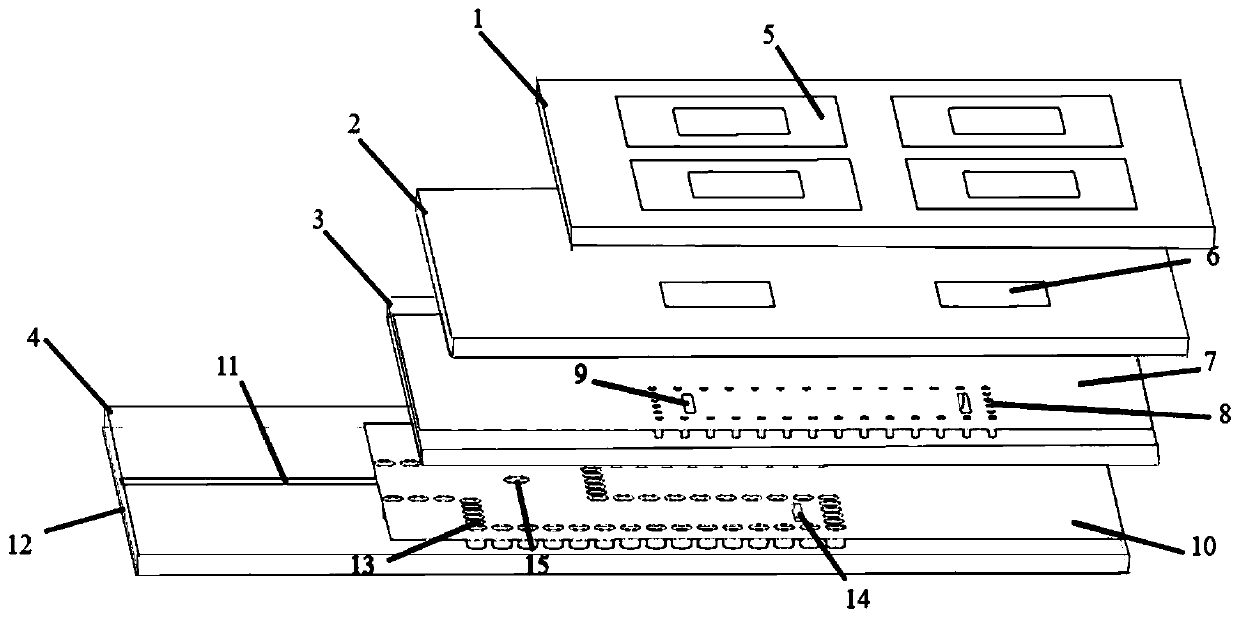

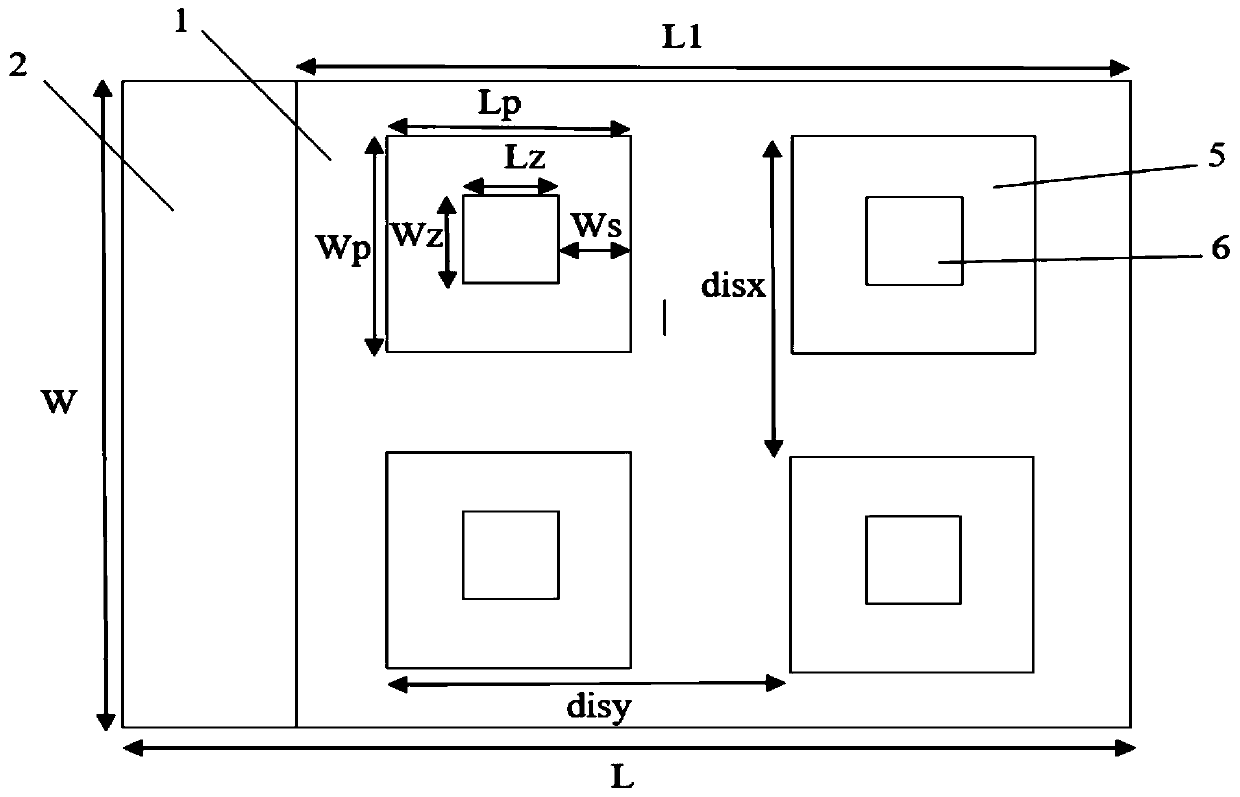

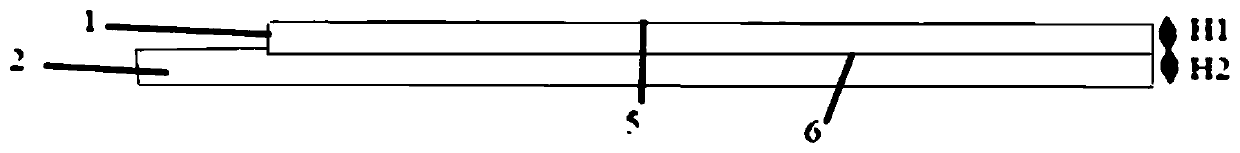

[0030] The substrate-integrated waveguide-fed parasitic patch array antenna of the present invention includes a first dielectric plate 1, a second dielectric plate 2, a third dielectric plate 3 and a fourth dielectric plate 4, wherein the first dielectric plate 1 is located on the second dielectric plate 2, the second dielectric plate 2 is located above the third dielectric plate 3, and the third dielectric plate 3 is located above the fourth dielectric plate 4. Four annular patches 5 arranged in two rows and two columns are arranged above the first dielectric plate 1, and four main radiation patches 6 arranged in two rows and two columns are arranged above the second dielectric plate 2. The pieces 6 are located directly below the annular patches 5 in one-to-one correspondence. The upper surface of the third dielectric plate 3 is the first metal layer 7, and the first...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com