Preparation method of zinc-iron flow battery with high energy density and low cost

A high-energy-density, low-cost technology, applied in fuel cells, battery electrodes, regenerative fuel cells, etc., can solve the problems of high cost and low energy density, and achieve low cost, high energy density, and low raw material prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In this example, the preparation method of the ion exchange membrane for the alkaline redox flow battery is as follows:

[0037] 1. The ionization treatment process of Nafion membrane / SPEEK membrane includes the following steps:

[0038] (1) Soak the Nafion membrane or SPEEK membrane with a length of 7.5cm and a width of 5.0cm in deionized water and wash it repeatedly;

[0039] (2) Nafion film or SPEEK film after cleaning is placed in the sodium hydroxide or potassium hydroxide or lithium hydroxide aqueous solution (the present embodiment is the sodium hydroxide aqueous solution that molar concentration is 1M) of 0.1~10M molar concentration, Ionize at a constant temperature of 60-100°C for 1-3 hours (in this example, ionize at a constant temperature of 80°C for 2 hours);

[0040] (3) After the ionized Nafion membrane or SPEEK membrane is cooled to room temperature, it is repeatedly washed with deionized water to neutrality, soaked in deionized water, and set aside;

...

Embodiment 2

[0050] The difference from Example 1 is that the preparation of the electrolyte:

[0051] Dissolve ferrocyanide (such as potassium ferrocyanide) in sodium hydroxide or potassium hydroxide or lithium hydroxide aqueous solution with a molar concentration of 0.1-2M (this example is an aqueous lithium hydroxide solution with a molar concentration of 1.5M) After being completely dissolved, an alkaline aqueous solution of ferrocyanide with a molar concentration of 0.9M is obtained, and a certain amount is placed in the positive electrode liquid storage tank to be used as the positive electrode electrolyte of the battery.

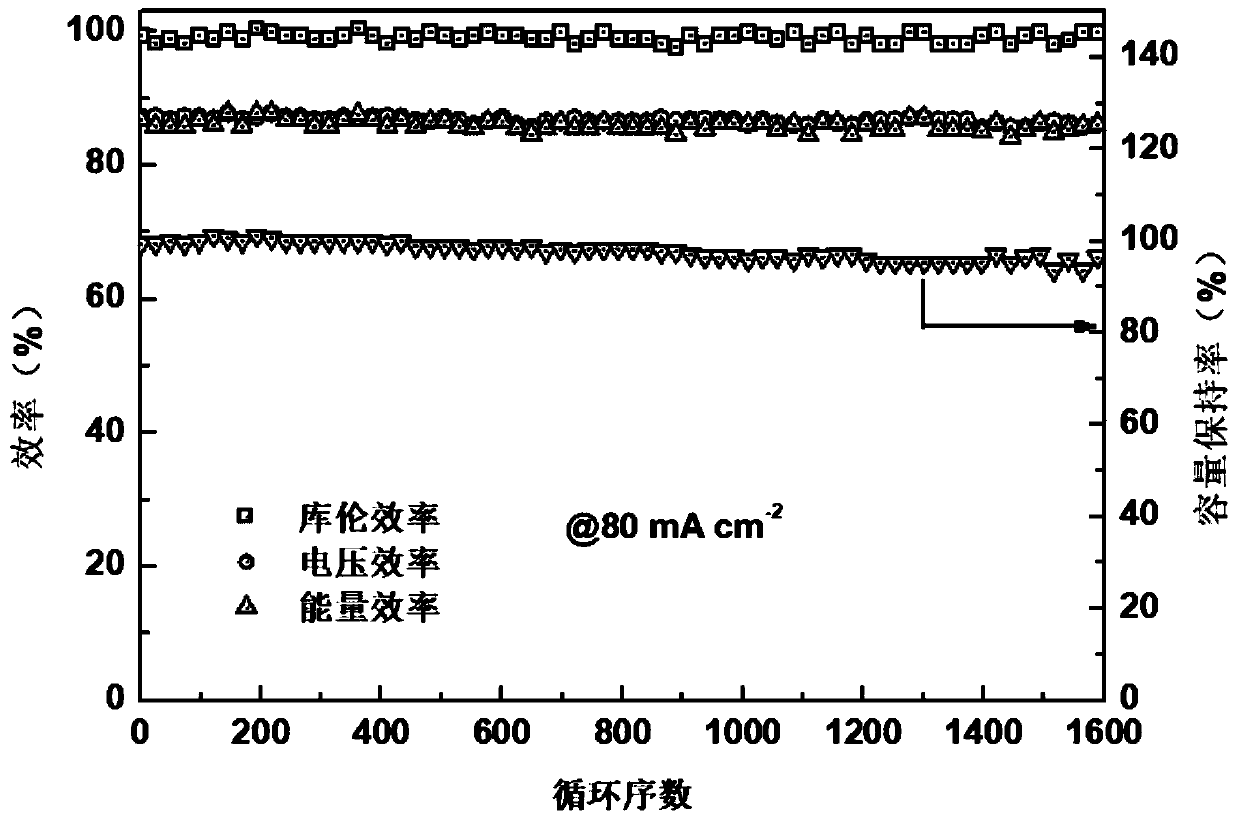

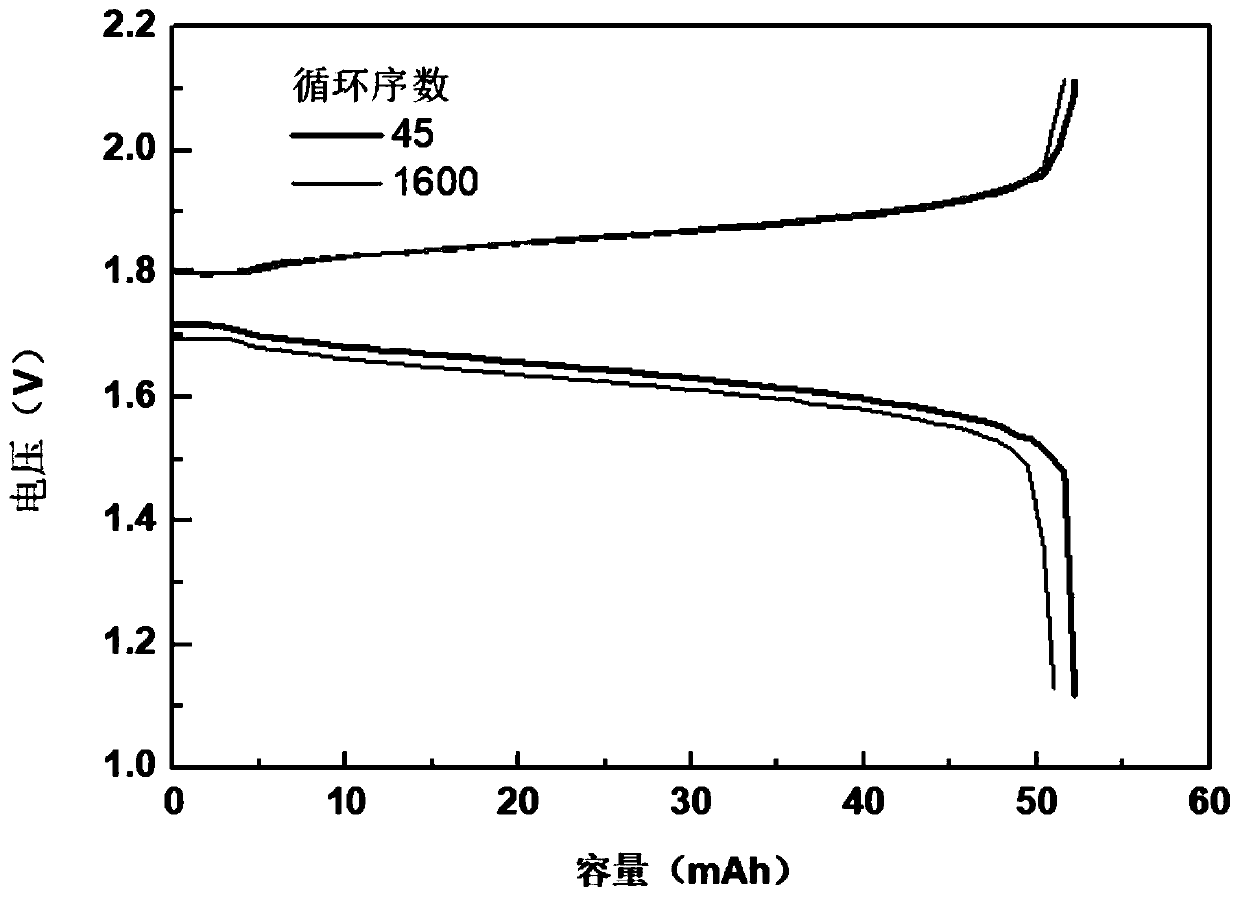

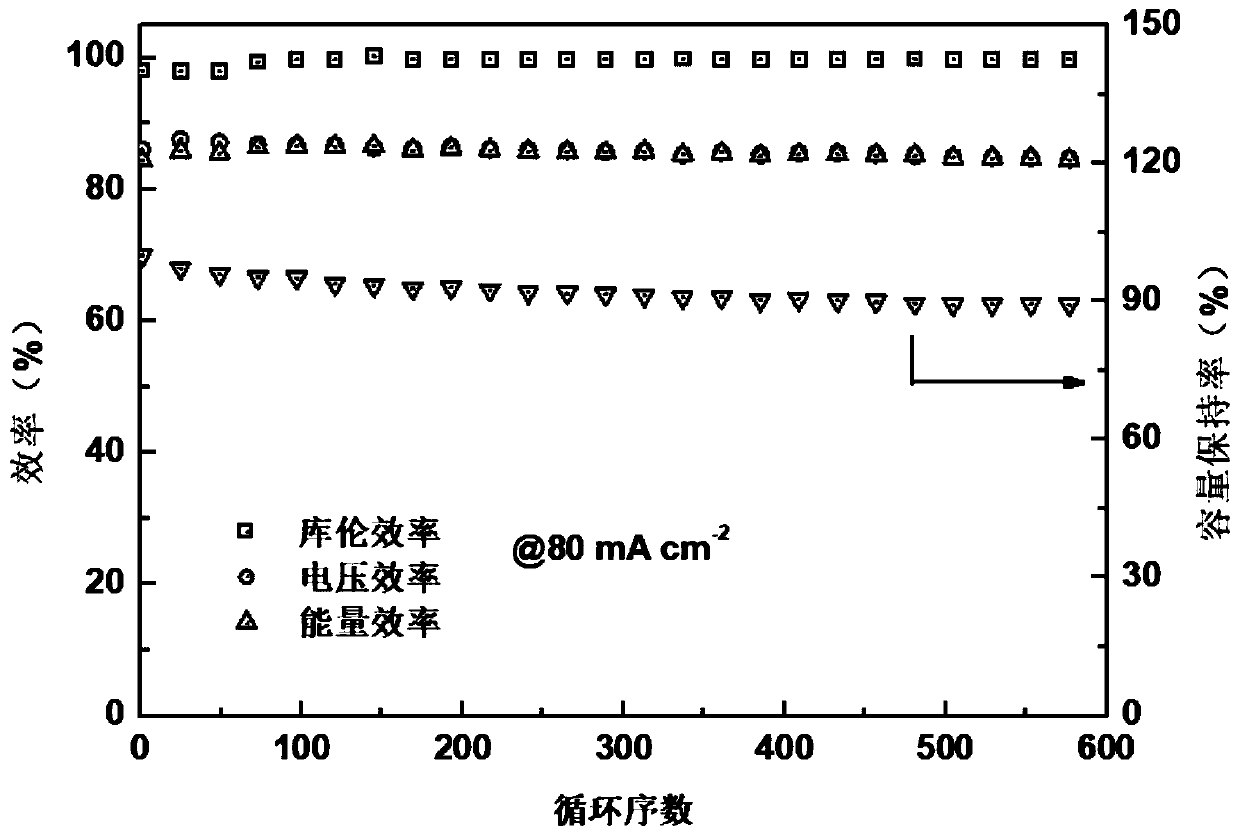

[0052] In this embodiment, the carbon felt is used as the positive electrode material of the flow battery, the zinc plate is used as the negative electrode material of the flow battery, and the ionized cation exchange membrane is used to assemble the flow battery of the system. The zinc-iron system flow battery assembled with the alkaline aqueous solution of ferro...

Embodiment 3

[0058] In this example, the preparation method of the ion exchange membrane for the alkaline redox flow battery is as follows:

[0059] 1. The ionization treatment process of PBI membrane comprises the following steps:

[0060] (1) Soak the PBI membrane with a length of 7.5cm and a width of 5.0cm in deionized water and wash it repeatedly;

[0061] (2) Place the cleaned PBI membrane in an aqueous potassium hydroxide solution with a molar concentration of 2M, and ionize it at a constant temperature of 90° C. for 1 h;

[0062] (3) After the ionized PBI film is cooled to room temperature, it is washed repeatedly with deionized water to neutrality, soaked in deionized water, and set aside;

[0063] 2. Preparation of electrode materials:

[0064] (1) Polish a zinc plate with a thickness of 4mm on 120-mesh sandpaper, clean it with deionized water and dry it with a hair dryer, and use it as the negative electrode material of the battery.

[0065] (2) Carbon felt and graphite felt w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com