Graphene homogeneous p-n junction structure and preparation method thereof

A technology of graphene and graphene layers, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as different chemical properties, performance parameter differences, doping effects, etc., to reduce dislocations and defects, improve performance Excellent, structurally stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

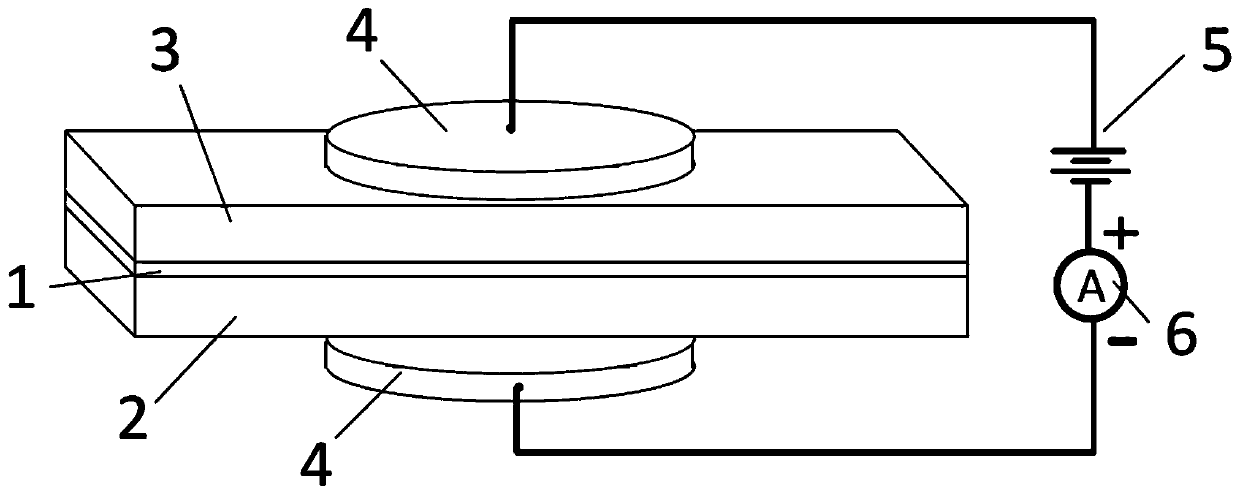

[0039] The preparation method of graphene homogeneous p-n junction structure of the present invention comprises following process:

[0040] Prepare p-type graphene layer 2 / neutral graphene layer 1 / n-type graphene layer 3 composite structure;

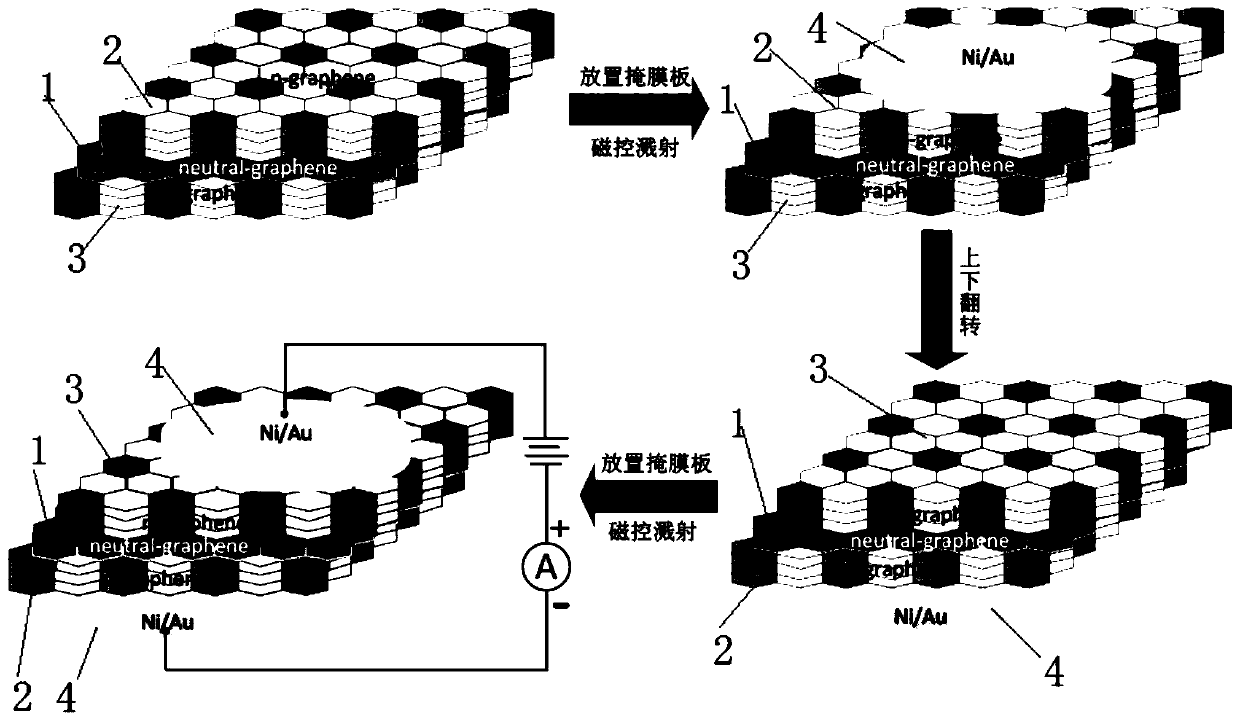

[0041] Electrodes 4 are prepared on the surface of the p-type graphene layer 2 and the surface of the n-type graphene layer 3 to obtain the graphene homogeneous p-n junction structure.

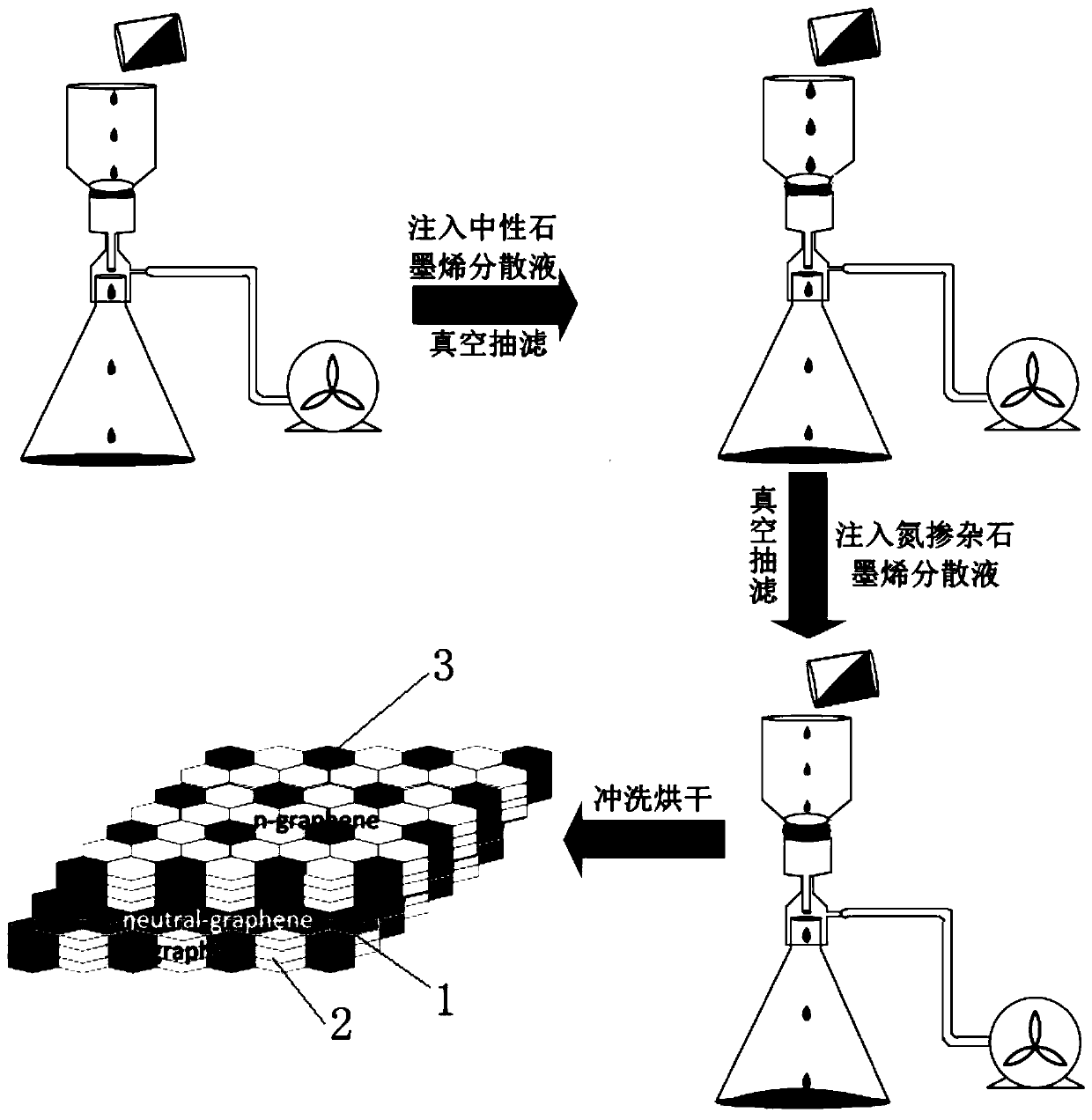

[0042] As a preferred embodiment of the present invention, the homogeneous p-n junction graphene-based paper of p-type graphene layer / neutral graphene layer / n-type graphene layer is prepared by vacuum filtration method, and then the homogeneous p-n junction graphene-based paper The paper is cleaned and dried to obtain a composite structure of p-type graphene layer / neutral graphene layer / n-type graphene layer, and the electrode 4 is prepared by magnetron sputtering.

[0043] As a preferred embodiment of the present invention, the neutral graphene layer 1...

Embodiment

[0045] In this example, the compound of graphene oxide and doped target atoms (boron, nitrogen) is used as raw materials, and the traditional vacuum filtration technology is used to prepare the graphene homogeneous p-n junction structure at one time, and the same material has thermal expansion coefficient, electronic The affinity energy, band gap width and lattice constant are all the same, which avoids the problem of interface characteristics caused by the heterojunction formed by different materials.

[0046] This embodiment adopts the following technical solutions to achieve:

[0047] 1. Preparation of boron-doped graphene and nitrogen-doped graphene;

[0048] 2. Prepare graphene homogeneous p-n junction by traditional vacuum filtration technology;

[0049] 3. Preparation of Ni / Au circular electrodes by magnetron sputtering.

[0050] Here are the detailed steps for each step:

[0051] 1. Preparation of boron-doped graphene and nitrogen-doped graphene

[0052] Graphene o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com