Extraction method of flavor components of rapeseed oil

A technology of flavor components and rapeseed oil, which is applied in material separation, material analysis, measuring devices, etc., can solve problems such as loss, and achieve the effects of short pretreatment time, real extraction components, and simple and efficient detection methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

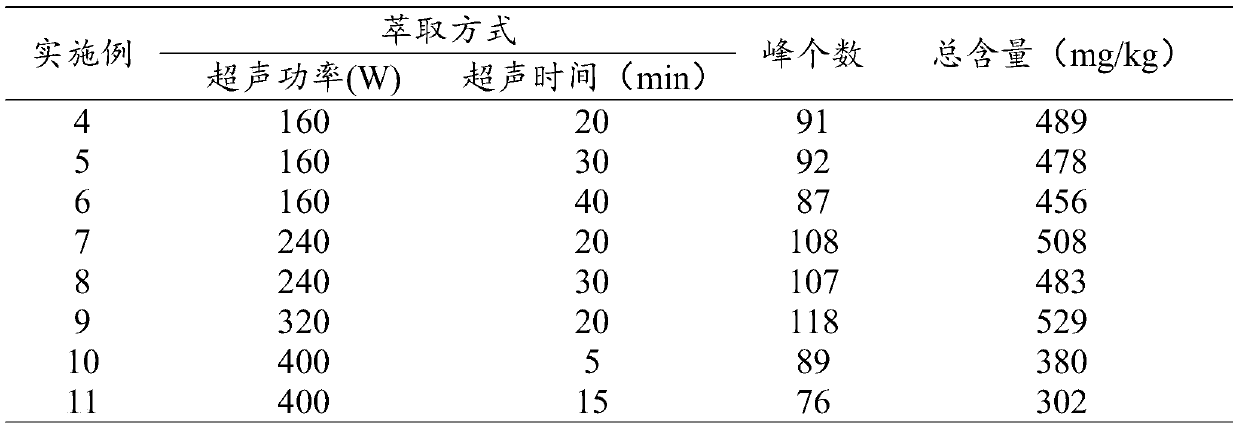

Examples

Embodiment 1

[0033] A method for extracting the flavor components of rapeseed oil, which specifically includes the following steps:

[0034] (1) Take 30g rapeseed oil sample to be tested in a 200mL flask, add 60mL dichloromethane to dissolve, set the power to 240W, and the ultrasonic time to 15min. Ultrasound in an ultrasonic cell disruptor with a probe to prepare a mixed solution.

[0035] (2) Use SAFE device for distillation separation. Use a constant temperature water bath to keep the 500mL flask on the left side of the SAFE device at 40°C, in a high vacuum (10 -6 KPa) distilled for 1h. After separation, the extract was further used anhydrous Na 2 SO 4 Dry, and then store in a refrigerator at -20°C for 4 hours to further remove any remaining water. The resulting extract was concentrated to 100 μL by gentle nitrogen.

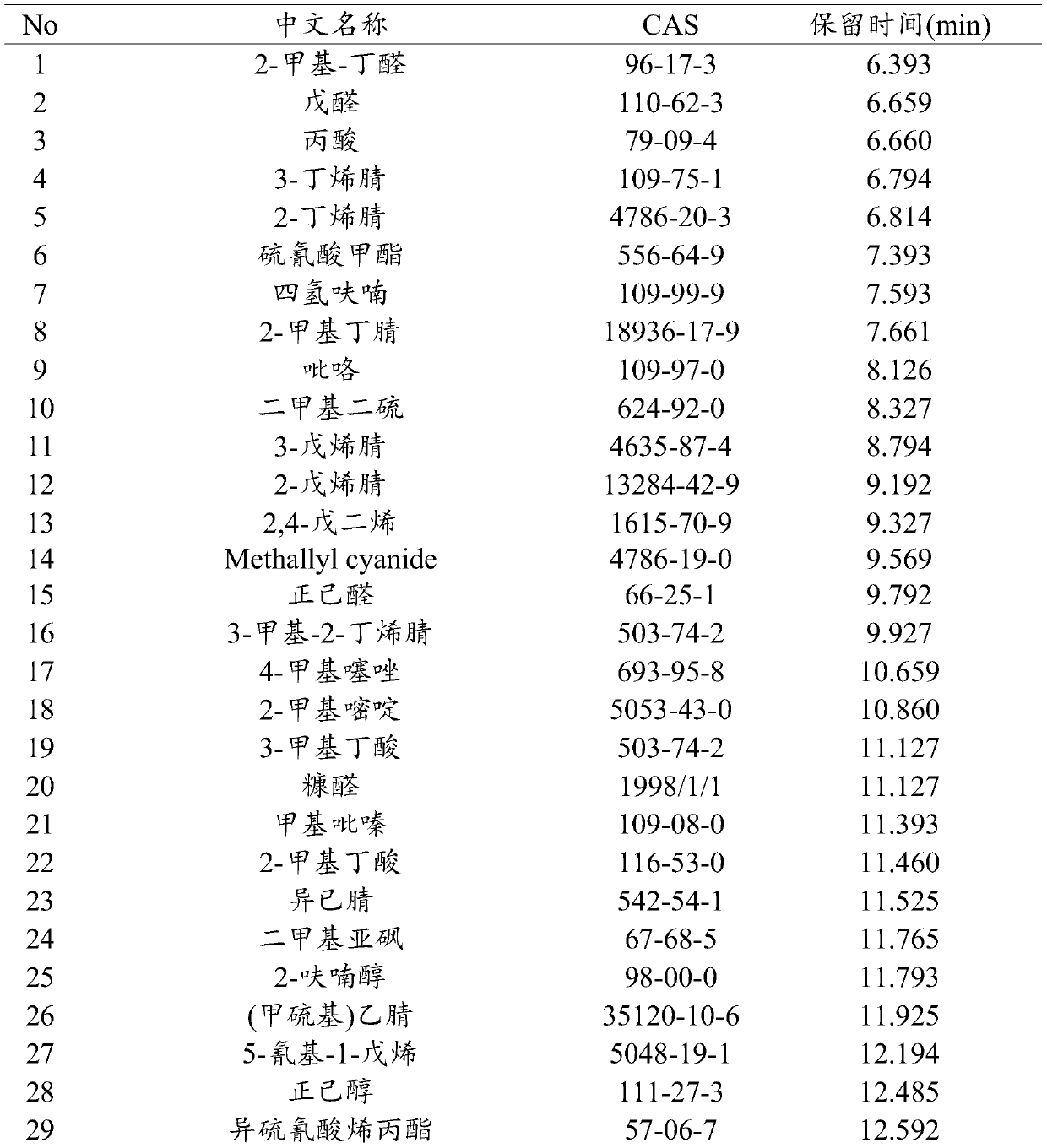

[0036] (3) Use Agilent 7890A gas chromatograph and 5975C mass spectrometer. Helium is used as the carrier gas at a rate of 1.5mL / min. HP-5MS chromatographic column (60m×0.25m...

Embodiment 2

[0039] A method for extracting the flavor components of rapeseed oil, which specifically includes the following steps:

[0040] (1) Take 40g rapeseed oil sample to be tested in a 200mL flask, add 100mL dichloromethane to dissolve, set the ultrasonic power to 400W, and the ultrasonic time to 10min. Ultrasound in an ultrasonic cell disruptor with a probe to prepare a mixed solution.

[0041] (2) Use SAFE device for distillation separation. Use a constant temperature water bath to keep the 500mL flask on the left side of the SAFE device at 40°C, in a high vacuum (10 -6 KPa) distilled for 1h. After separation, the extract was further used anhydrous Na 2 SO 4 Dry it and store it in a refrigerator at -20°C for 6 hours to further remove any remaining water. The resulting extract was concentrated to 100 μL by gentle nitrogen.

[0042] (3) Use Agilent 7890A gas chromatograph and 5975C mass spectrometer. Helium is used as the carrier gas at a rate of 1.5mL / min. HP-5MS chromatographic colum...

Embodiment 3

[0045] A method for extracting the flavor components of rapeseed oil, which specifically includes the following steps:

[0046] (1) Take 50 g of rapeseed oil sample to be tested in a 200 mL flask, add 150 mL of dichloromethane and 100 μL of 2-methyl-3-heptanone as internal standard compounds for quantification. The ultrasonic power is 320W, and the ultrasonic time is 30min. Ultrasound in an ultrasonic cell disruptor with a probe to prepare a mixed solution.

[0047] (2) Use SAFE device for distillation separation. Use a constant temperature water bath to keep the 500mL flask on the left side of the SAFE device at 30°C, in a high vacuum (10 -6 KPa) distilled for 1h. After separation, the extract was further used anhydrous Na 2 SO 4 Dry and store in a refrigerator at -20°C for 8 hours to further remove any remaining water. The resulting extract was concentrated to 100 μL by gentle nitrogen.

[0048] (3) Use Agilent 7890A gas chromatograph and 5975C mass spectrometer. Helium is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com