Intelligent detection method and device for KIT board

A technology of intelligent detection and template, applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems such as difficult realization, lack of workpieces, detection, etc., to improve accuracy and detection efficiency, save manpower, avoid rework and maintenance work Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

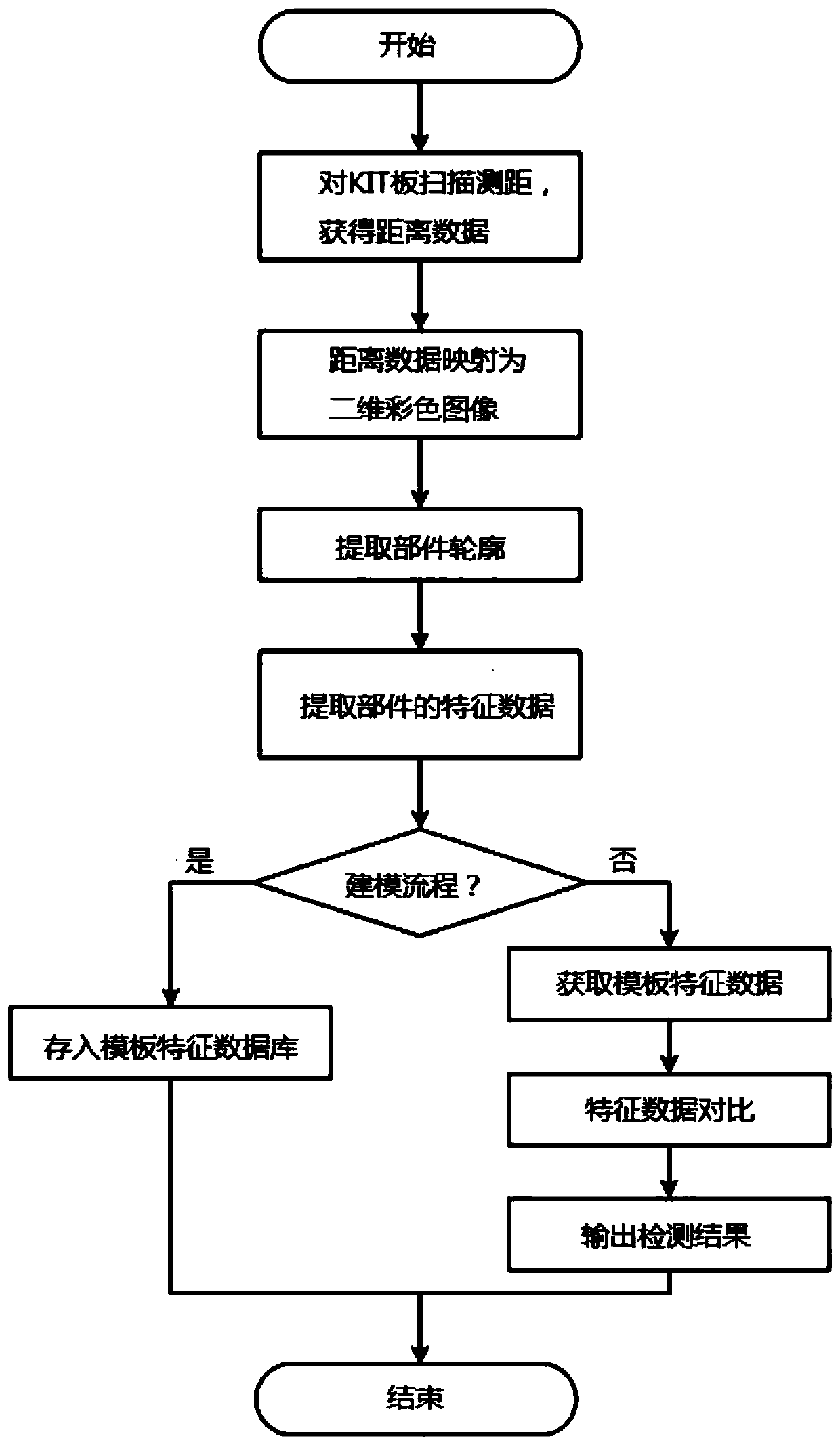

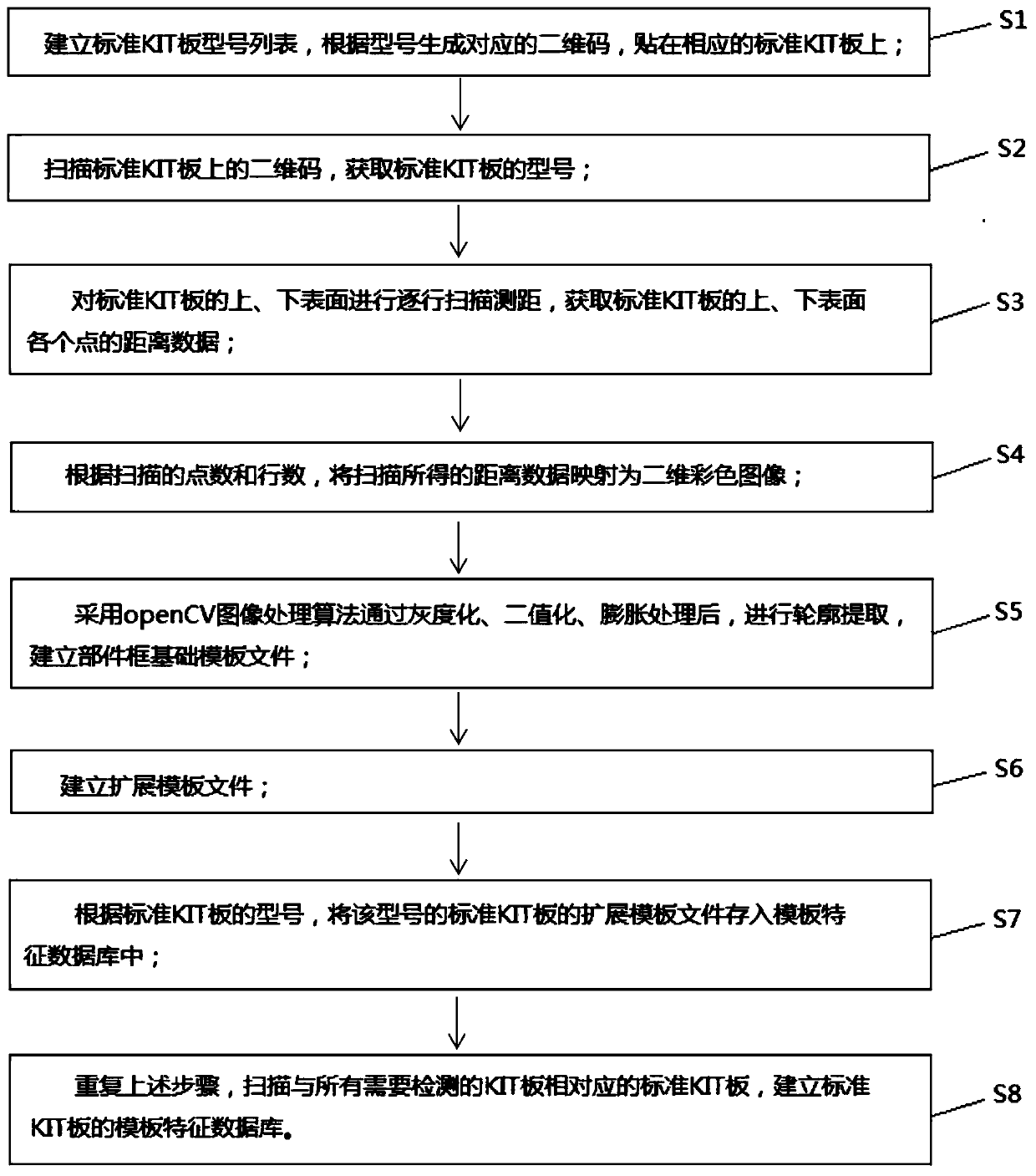

[0061] The intelligent detection method of the KIT board that this embodiment provides, see figure 1 , which is divided into two parts: modeling and detection. Scan and measure the KIT board, map the scanned distance point cloud data into a two-dimensional color image, use the OpenCV image processing algorithm to extract the component contour information, and calculate the area, grayscale, height and other feature data in the component contour area. During modeling, the feature data is stored in the template feature database; during detection, the feature data is the object to be compared with the template feature data.

[0062] In order to make the method of the present invention more clear, modeling and detection will be described separately below. But in practice, modeling and detection can be combined. For example, when scanning a standard KIT board, its feature data is the modeling data; when scanning a test KIT board, its feature data is the object to be compared. Aft...

Embodiment 2

[0099] This embodiment provides a device for implementing the intelligent detection method for a KIT board in the first embodiment above. see Figure 8 , the device specifically includes:

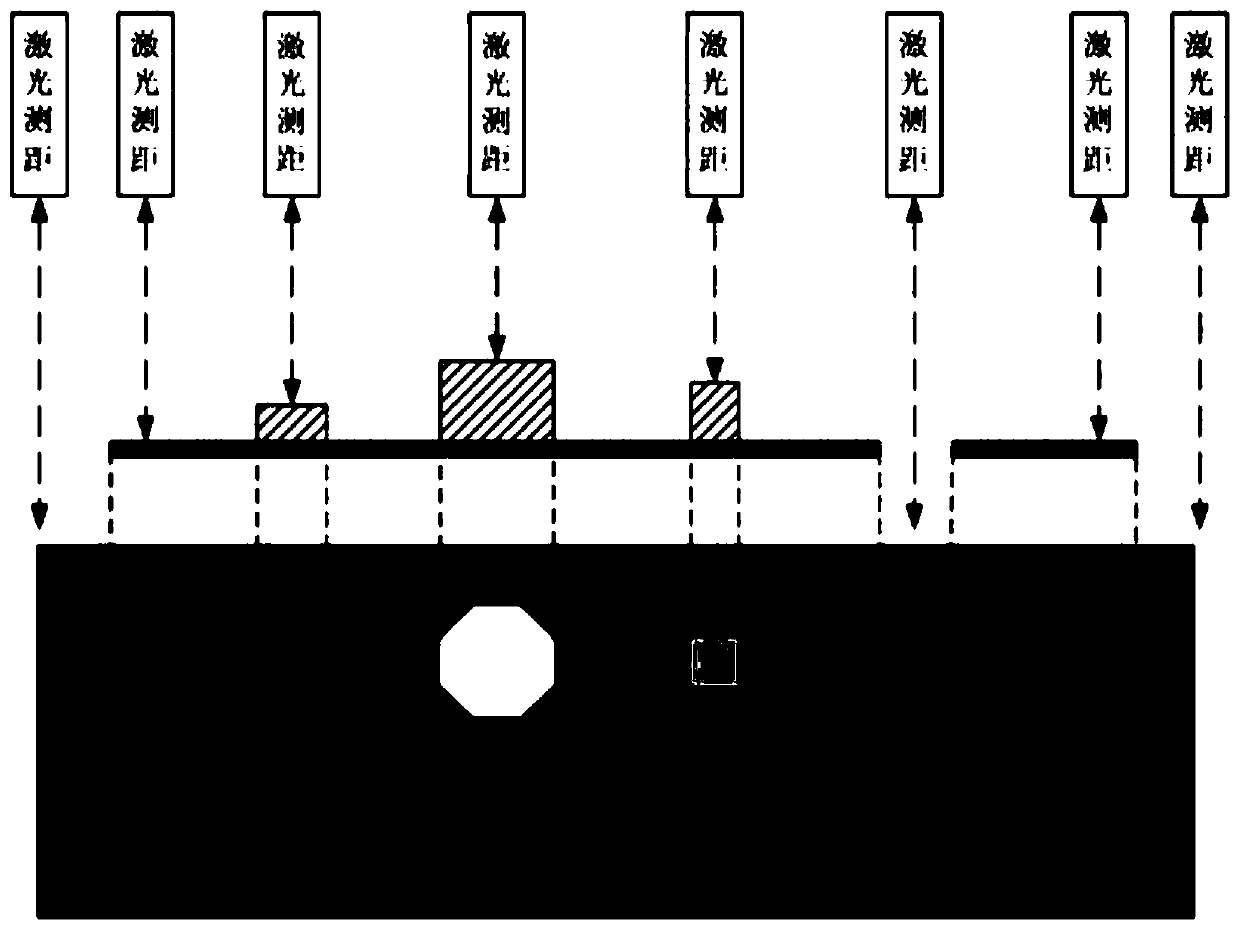

[0100] The scanning distance measurement module 1 scans and measures the standard KIT board, and obtains the distance between each point on the standard KIT board and the scanner;

[0101] Image mapping module 2, which maps the measured distance to a two-dimensional color image;

[0102] The basic template building module 3 uses the openCV image processing algorithm to extract the outline of the part in the two-dimensional color image to obtain the basic template file of the part;

[0103] Extended template builds module 4, according to the outline in basic template file, calculates the feature data of each part, saves as template feature data, obtains extended template file; Described feature data includes gray value, area value and height value;

[0104] Template characteristic databas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com